Fabric 101: How to ID Fabric by Fiber, Weave, and Fire

When it comes to fabrics, knowledge is power. Whether you’re a fabric wholesaler, fashion designer or garment manufacturer, knowing textiles inside and out can take your business to the next level. This comprehensive guide to Fabric 101 (also known as Textiles 101) will help you identify fabrics by their fibers, weaving techniques and other key characteristics so your purchasing, designing or manufacturing decisions are always informed.

From the raw fibers that make up every textile to the advanced finishes that add performance and value, consider this blog your roadmap to mastering fabric knowledge.

What Is Fabric?

Before we get started it’s important to clarify a key distinction in industry terminology:

-

Textiles refer to any material made from interlacing fibers. Unfinished fabric straight off the loom or unprocessed raw materials fall under this category.

-

Fabrics are finished textiles that are processed and ready for cutting, sewing and use in production.

-

Cloth is a fundamental material produced from fabrics, widely used for making garments, household items, and various industrial products.

For wholesalers, understanding these terms means accurate communication with suppliers and clients. For designers and manufacturers, it means precise material selection for specific applications.

Module 1: Fiber Types – The Building Blocks of Fabric

Understanding a fabric’s fiber type is the first step to identifying its look, feel and functionality. Fibers are generally categorized as either natural fibers, which are derived from plants or animals, or man made fibers, which are created through synthetic or semi-synthetic processes. Man made fibers include both synthetic fibers, such as nylon and acrylic, and semi-synthetic fibers like rayon.

Natural Fibers

Natural fibers come from plant or animal sources. Cotton, for example, is a plant-based fiber known for its softness and breathability, and has been used as a fabric since prehistoric times. Linen, another plant-based fiber, is valued for its coolness and strength. Linen fabrics are especially prized for their breathability, durability, and are commonly used in sewing, embroidery, upholstery, and household textiles. Wool, derived from sheep, is warm and resilient, and has a rich history dating back to the use of plant fibers. Animal fibers also include hair fibers, such as those from goats (cashmere, mohair) and rabbits (angora), which are known for their elasticity, moisture absorption, and require special care due to their susceptibility to insects. Silk, produced by silkworms, is renowned for its luster and smooth texture. Artificial silk, such as rayon, was developed as an affordable alternative to silk, offering similar lightweight and flowy characteristics. Before the development of woven fabrics, animal hides were among the initial materials used by humans for protection.

Synthetic and Man Made Fibers

Synthetic fibers are man made fibers designed to mimic natural fibers, offering versatility and a wide range of applications. Common types of synthetic fiber include nylon and acrylic, both of which are used extensively in fashion, upholstery, and home décor. Acrylic, in particular, is popular for its durability, color retention, and resistance to environmental factors. After the development of synthetic fibers, rayon emerged as the first man made fiber, classified as a semi-synthetic fiber derived from natural cellulose sources. Rayon is lightweight, breathable, and easily dyed, making it a popular choice for clothing. Rayon fabric shares similarities with natural fibers like silk and cotton, and is especially suitable for hot and humid climates.

Natural Fibers

Natural fibers come from plants or animals, offer a premium hand feel and breathability.

-

Cotton - Soft, moisture absorbent and versatile. Egyptian and Pima cotton are the best.

-

Silk - Luxurious and smooth with natural shine. Most famous for elegant drapes.

-

Wool - A natural insulator that’s good for cold weather wear, from merino to heavier tweeds.

-

Linen - Lightweight, crisp and breathable, perfect for warm climates.

Synthetic Fibers

Synthetics bring durability, elasticity and affordability to the table.

-

Polyester - Resists wrinkles and shrinkage, perfect for everyday wear.

-

Nylon and Spandex - This combination yields a lightweight, strong, and stretchy fabric, making it ideal for activewear, swimwear, and fitted garments like leggings.

Blends, like cotton-polyester, combine the best of both worlds to balance performance and design.

Module 2: Yarn Structure

Yarn structure is a crucial factor in determining the final qualities of any fabric. The way fibers are spun together to create yarn directly impacts the texture, durability, and appearance of the finished product. When selecting the right fabric for your next project, understanding yarn structure can help you achieve the desired look and feel.

There are several types of yarn structures commonly used in the textile industry. Single-ply yarns are created from a single strand of fibers, resulting in a softer, more flexible fabric, but sometimes at the expense of durability. Multi-ply yarns, on the other hand, are made by twisting two or more strands together, which increases strength and resilience—ideal for upholstery fabrics or garment fabrics that need to withstand frequent use. Textured yarns are engineered by twisting or curling the fibers, adding unique surface interest and enhancing the fabric’s tactile qualities.

By considering how yarns are created and structured, you can better match your fabric choices to the demands of your project, whether you’re aiming for a soft drape in evening wear or the robust durability needed for home decor or upholstery fabric.

Module 2: Yarn StructureYarns are spun into fabrics, the next link in the chain.

-

Yarn Count & Twist - Determines the fineness and strength of the fabric. Higher counts and tighter twists mean durability and smooth texture. Threads, as the fundamental units in textile weaving and fabric construction, are combined and manipulated to create different textures and intricate patterns in fabrics.

-

Single vs. Plied Yarns - Single yarns are cost effective but may lack strength, whereas plied yarns add durability. High-end products often go for 2-ply or cabled yarns.

Knowing this makes it easier for designers and wholesalers to match their choices to product goals, like creating luxurious long-lasting garments.

Module 3: Weave & Knit

The structure and texture of fabrics is determined by how yarns are interlaced. Woven fabric is created by interlacing yarns at right angles, resulting in a stable and structured textile suitable for apparel, upholstery, and decor. In contrast, knitted fabric is made by interlocking yarns in loops, giving it more stretch and flexibility, which makes it ideal for comfortable, form-fitting garments. Knit fabric, known for its stretchiness, is commonly used in T-shirts, athletic wear, and dresses.

Patterns in textiles can be created through weaving, printing, or advanced techniques like Jacquard, which produces intricate woven designs. Print and printed fabrics involve applying designs to the fabric surface, resulting in flat patterns that can fade over time, unlike woven patterns that are integrated into the fabric’s structure.

Woven Fabrics

Woven fabric is created by interlacing yarns at right angles, resulting in a stable and structured textile suitable for apparel, upholstery, and decor. The weft threads are densely woven across the warp threads, creating the structure and texture of woven fabrics and often concealing the warp for a smooth, durable finish. Yarn dyed fabrics are woven with dyed yarns, which enhances durability and color longevity in the finished textile.

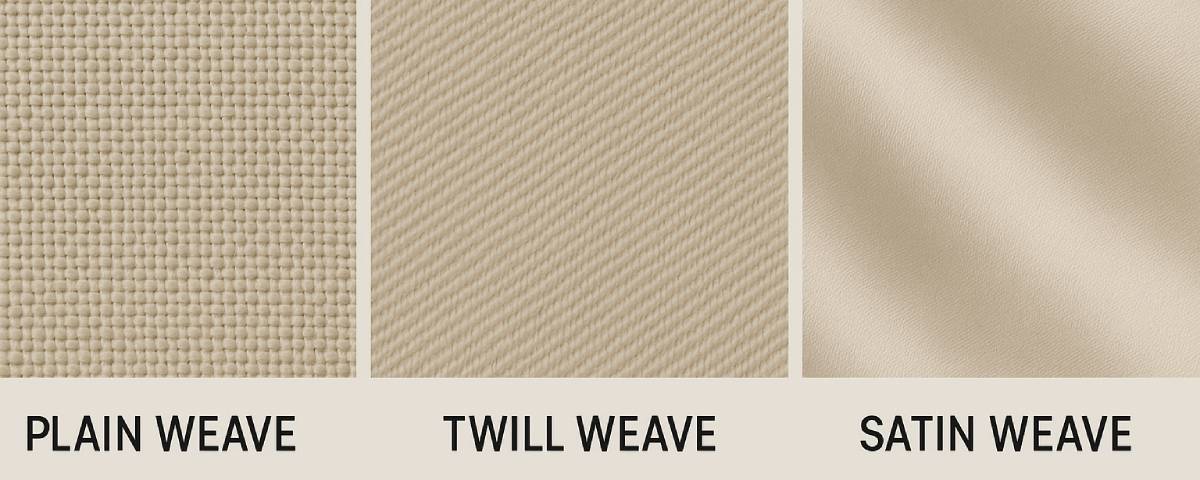

Woven fabrics provide structure and come in three main types of weaves:

-

Plain Weave - The simplest weave, used in shirts and bedding. Plain weave fabric is commonly used for bed sheets due to its durability and softness.

-

Twill Weave - Adds diagonal patterns, good for denim or suiting. Twill fabric is a durable and versatile woven textile characterized by a diagonal pattern, making it popular in items like denim and tweed.

-

Satin Weave - Smooth and shiny, often used in evening wear.

Jacquard is another type of fabric, featuring intricate woven patterns that are integrated into the fabric's construction, often used in upholstery and drapery.

Knitted Fabrics

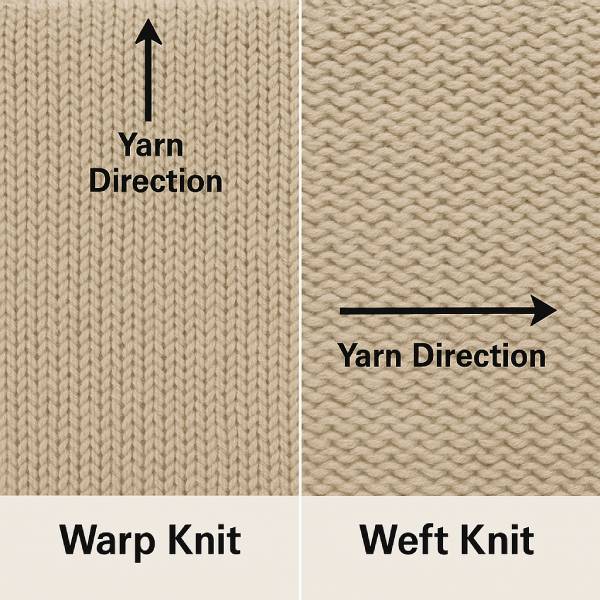

Knits are softer and more forgiving in their stretch, good for casual and activewear:

-

Weft Knits - Stretchy and versatile, including fabrics like jersey.

-

Warp Knits - More stable and durable, used in lingerie.

Both weaving and knitting have their benefits. Having both options means wholesalers can meet diverse client needs.

Module 4: Finishing & Functional Treatments

Fabric finishing turns raw textiles into ready-to-wear masterpieces.

-

Dyeing & Printing - Techniques like reactive dyeing or digital printing for vibrant, fade resistant colours. Printed fabrics have designs applied to the surface through print methods, creating flat patterns that can fade over time, unlike woven patterns where the design is part of the fabric structure.

-

Mechanical Finishes - Processes like brushing or calendering to soften the fabric or add water repellency.

-

Chemical Coatings - Treatments like Teflon for functional benefits like UV protection, stain resistance or anti-wrinkle performance.

Manufacturers can use finishing treatments to add value and create bespoke products for niche markets.

Module 5: Key Performance Metrics

Measuring fabrics means understanding measurable qualities like:

-

GSM (g/m²) - Controls fabric weight and drape.

-

Tensile Strength - Indicates durability and tear resistance.

-

Abrasion Resistance - Determines long wear capability under stress (e.g. Martindale tests).* Moisture Management - Wicking and absorbency.

Measuring these helps clients match design or manufacturing goals and ensures consistency.

Application Scenarios

Fabrics are designed for industries:

-

Apparel - Activewear, formal wear or swimwear each have different performance requirements. The clothing industry plays a crucial role in fabric selection and garment production, ensuring the right materials are used for comfort, durability, and style.

-

Home Textiles - Durability and colorfastness for bedding or upholstery are essential. The choice of fabric for furniture upholstery is important, as furniture fabrics must offer durability, variety, and aesthetic appeal to enhance and extend the lifespan of furniture pieces. For bed sheets, fabrics like cotton and polyester are popular due to their softness, durability, and stain resistance.

-

Industrial Use - Technical textiles meet specific engineering or medical requirements like FDA approved filters.

Mapping fabrics to their use allows professionals to tailor their offerings and streamline supply chains.

Textile manufacturing and production also have a significant impact on fashion trends, shaping current styles and influencing design preferences.

Fabric Selection and Shopping

With so many fabric types available, selecting the right fabric for your project can feel daunting. However, a better understanding of fabric types, their structure, and intended use can make the process much more manageable. When shopping for fabric, it’s important to think about the purpose of your project, the desired drape and texture, and how much durability you’ll need from the finished product.

Whether you’re browsing for garment fabrics, upholstery fabrics, or materials for a new project, take time to compare different fabric types. Consider how the fabric will perform in real-world use, how it will feel against the skin, and how it will hold up over time. This thoughtful approach ensures you’ll select the right fabric every time, resulting in a finished product that meets your expectations for both style and function.

How to Choose the Right Fabric for Your Project

Choosing the right fabric starts with understanding the specific needs of your project. For garments that require stretch and comfort, knit fabrics such as cotton jersey, polyester blends, or spandex are excellent choices. These fabrics, created through interlocking loops, offer flexibility and a soft drape, making them ideal for activewear, t-shirts, or fitted clothing.

For home decor projects like curtains or upholstery, woven fabrics are often preferred. Options like linen, cotton, or synthetic fibers provide structure, durability, and a crisp finish—perfect for items that need to maintain their shape and withstand daily use. When selecting fabric for upholstery, look for tightly woven materials that can handle frequent wear and tear.

Don’t forget to consider the care requirements of each fabric, as well as any sensitivities to certain fibers. By matching the fabric’s properties—such as drape, durability, and fiber content—to your project’s needs, you’ll ensure a successful outcome, whether you’re sewing a new garment or updating your home decor.

Tips for Visiting a Fabric Shop

A trip to the fabric shop can be both exciting and overwhelming, especially with all the different fabric types on display. To make your visit more productive, start by familiarizing yourself with the fabric types you’re interested in and have a clear idea of what you need for your project. Bringing a swatch or sample can help you match colors and textures more accurately.

Don’t hesitate to ask the knowledgeable staff for advice—they can guide you to the right fabric for your needs and help you understand the differences between materials. Always check the care and maintenance instructions for each fabric, and if you’re unsure, ask for assistance. Visiting during quieter hours can give you more time to explore and compare all the different types of fabric available, ensuring you make the best choice for your next project.

Fabric Care and Maintenance

Taking proper care of your fabric is essential for preserving its beauty and extending its lifespan. Whether you’re working with delicate silks, sturdy cottons, or luxurious wool fabrics, understanding the best practices for cleaning, washing, and storing your fabrics will keep them looking their best for years to come.

Cleaning, Washing, and Preserving Your Fabrics

Each fabric type requires specific care to maintain its quality and appearance. Delicate fabrics like silk, wool, and velvet often need gentle hand washing or professional dry cleaning to protect their fibers and prevent damage. More durable fabrics, such as cotton or synthetic fibers like polyester and nylon, can usually be machine washed, but it’s always wise to check the care label for precise instructions.

To preserve your fabrics, consider using fabric protectors that help repel stains and spills, and always test cleaning methods on a small, hidden area first. Proper storage—such as keeping fabrics out of direct sunlight and away from moisture—will also help maintain their color and texture. By following these care guidelines, you’ll ensure your fabrics remain vibrant, soft, and ready for your next sewing or upholstery project.

Sustainable & Eco-Friendly Textiles

Environmental responsibility is no longer optional in fabric choice.

-

Recycled Fibers - Polyester made from post-consumer waste like plastic bottles.

-

Organic & Regenerative Fibers - Certified organic cotton or hemp reduces the ecological footprint of your collection.

-

Low-Impact Dyes - Waterless dyeing and renewable processes are the future of textiles.

Sustainability not only saves the planet but also meets consumer demand and sets you apart in the market.

Get Your Fabric Knowledge

Mastering Fabric 101 helps wholesalers, designers and manufacturers:

-

Wholesalers to position their inventory.

-

Designers to innovate.

-

Manufacturers to produce to quality standards.

Ready to level up your fabric knowledge? Subscribe to our weekly blog or get in touch for sourcing advice. Whether you’re sourcing raw textiles or launching your next collection, fabric fundamentals are key to staying ahead in the industry.