The Rise of Recycled Non Woven Fabric as an Eco-Friendly Solution

Environmental consciousness is no longer optional in industries worldwide. Businesses and manufacturers are actively seeking sustainable alternatives that reduce their carbon footprint while meeting quality and performance standards. The industry must respond to these demands by developing sustainable alternatives like plastic-free products and increasing their portfolio of biodegradable and compostable options. Protecting the environment through sustainable practices is crucial. Among these solutions, recycled non woven fabric has emerged as a versatile, cost-effective, and eco-friendly material set to transform the textile and industrial landscape. Additionally, addressing environmental pollution, recycled non woven fabric helps mitigate emissions and waste, aligning with eco-friendly initiatives.

This blog explores what recycled non woven fabric is, its environmental and economic benefits, its diverse applications, how it is manufactured, and what the future holds for this innovative material.

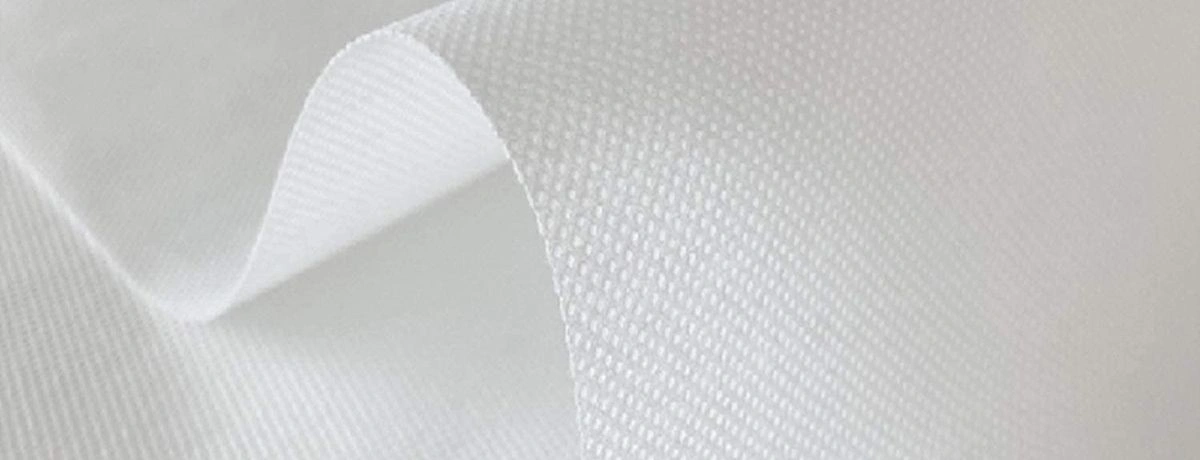

Understanding Recycled Non Woven Fabric

Recycled non woven fabric is created from reused or post-consumer materials, often including polypropylene fibers or polyester. Unlike traditional fabrics that are woven or knitted, these fabrics are bonded through mechanical, chemical, or thermal processes, making the production process simpler and more cost-effective while resulting in a flexible, durable, and lightweight material.

The increasing importance of this fabric lies in its ability to reduce waste and the continued demand for environmentally friendly materials. The growing demand for such materials has been particularly notable in sectors like hygiene and medical PPE, driven by the COVID-19 pandemic. With industries like healthcare, construction, and packaging exploring sustainable practices, recycled non woven fabric plays an essential role in enabling businesses to meet eco-friendly goals.

The Benefits of Recycled Non Woven Fabrics

1. Environmental Advantages

Switching to recycled non woven fabric directly impacts the planet, reducing waste and conserving energy. Key benefits include:

-

Reduction in Landfill Waste: Recycled non woven fabric repurposes post-consumer materials that would otherwise end up in landfills. This contributes to environmental protection by minimizing waste.

-

Lower Energy Consumption: Recycling uses less energy compared to producing virgin materials, thereby decreasing greenhouse gas emissions.

-

Eco-Friendly Disposal Options: Many recycled non woven fabrics are biodegradable or recyclable, ensuring minimal environmental impact after use. Additionally, the integration of plant-based materials in these fabrics enhances their sustainability, offering biodegradable and compostable options that align with consumer demand for innovative, eco-friendly solutions.

2. Economic Benefits

Using recycled materials doesn’t just support environmental goals; it’s also cost-effective:

-

Cost Savings: The production process of nonwoven materials is typically faster and requires fewer resources than traditional fabrics, leading to reduced costs. Over the years, these savings can accumulate significantly, making it a financially sound choice for businesses. Additionally, improving product offerings to include more sustainable options can further enhance cost efficiency and market appeal.

-

Business Appeal: Sustainability credentials are a major selling point for businesses aiming to attract environmentally conscious consumers. The expertise of our team in developing innovative and sustainable nonwoven materials ensures that we meet the evolving expectations for eco-friendly products.

Applications of Recycled Non Woven Fabric

The versatility of recycled non woven fabric is evident in the wide range of industries it supports. Companies such as Pratrivero and Freudenberg Performance Materials are leading the way in adopting these materials, utilizing recycled fibers and engaging in manufacturing processes that minimize environmental impact while meeting market demands for eco-friendly products. The demand for recycled non woven fabrics is particularly high in developed countries in Europe, driven by environmental benefits and sustainable characteristics. Additionally, various types of nonwoven materials, including compostable, renewable raw materials, and those with recycled content, contribute to sustainability in textiles. Here are some of its most notable uses:

1. Protective Clothing

Nonwovens are a key material in protective wear like masks, gloves, and gowns, which protect against microorganisms and became especially vital during the COVID-19 pandemic. Its lightweight yet durable properties ensure safety without compromising comfort.

2. Construction Materials

The construction industry has adopted non woven fabric for insulation, roofing, and moisture barriers. Its lightweight nature simplifies installation, while its efficient use of space makes storage and transportation easier. Nonwoven materials are less voluminous compared to traditional woven or knitted fabrics, which contributes to reduced fuel costs during transportation. Its durability enhances structural longevity.

3. Packaging Solutions

Eco-conscious businesses are increasingly using recycled non woven fabric in reusable shopping bags, gift packaging, and protective packaging materials. Customers are driving the demand for sustainable packaging solutions, pushing businesses to innovate and meet these expectations. Its strength and reusability make it a winning choice. Additionally, the role of water in the production of recycled non woven fabrics is crucial, as careful management of water resources helps minimize usage and reduce environmental impact. Shipping costs for non-Canadian and non-US orders, as well as orders under $150, are calculated based on weight, providing transparency regarding additional costs such as customs and duties for international orders.

4. Clothing and Hygiene Products

A mix of recycled non woven fabric with cotton or viscose fibres is often used in manufacturing a variety of clothing and personal hygiene products such as intimate wear, baby diapers, and wet wipes. Additionally, hemp is increasingly being utilized as a sustainable fiber in these products, highlighting its potential as a renewable raw material. Its softness and skin-friendly qualities make it ideal for such applications.

5. Sustainability Credentials

Brands committed to aligning with their consumers’ growing preference for sustainability use recycled non woven fabric to emphasize their dedication to reducing the environmental impact, differentiating themselves in the market. Additionally, these brands highlight the increasing share of sustainable nonwovens in their product portfolios, driven by consumer awareness and legislative pressures.

How Recycled Non Woven Fabric is Manufactured

The manufacturing process of recycled non woven fabric involves a systematic series of steps to ensure the fabric meets quality and performance standards. The use of raw materials, particularly recycled materials sourced from plastic waste, plays a crucial role in this process, contributing to reduced oil consumption and lower carbon emissions.

In terms of sustainability, it is essential to adhere to specific terms related to sustainability certifications. These certifications ensure that the production techniques align with eco-friendly practices and reinforce the commitment to environmental protection.

1. Collection and Sorting

Post-consumer materials, such as used polypropylene or polyester, are collected and sorted to remove impurities.

2. Cleaning and Breaking Down

Once sorted, these materials are cleaned and broken down into small fibers or flakes, depending on the desired end-use.

3. Bonding Process

The fibers are then bonded together through mechanical, chemical, or thermal processes. The choice of bonding technique determines the fabric’s characteristics, such as strength, flexibility, and breathability.

4. Quality Control

The final step is rigorous quality testing to ensure the durability, safety, and usability of the fabric. This ensures compliance with industry standards for various applications.

Future Trends in Recycled Non Woven Fabric

The future of recycled non woven fabric is marked by innovation and expanding applications. As market demand for sustainable products continues to grow, companies are focusing on expanding their offerings to meet environmental concerns and consumer preferences for greener alternatives. A key focus is on strategic sustainability initiatives, particularly emphasizing sustainable nonwoven products. Here’s what to expect:

Questions about sustainability and the use of synthetic nonwovens are driving innovation in the industry, pushing companies to develop greener alternatives and improve their sustainability practices.

1. Advanced Material Blends

Research and development efforts are focused on enhancing the properties of recycled non woven fabric by blending it with advanced materials to create products with even greater functionality. In addition, integrating new materials and processes further enhances these properties, demonstrating a commitment to innovation and sustainability.

2. Enhanced Circular Processes

Technological advancements in the recycling process will allow for even more efficient conversions of waste into reusable fabric, further reducing environmental impact.

The reuse of waste materials, such as plastic bottles, in recycled nonwoven fabric production not only reduces oil consumption and carbon emissions but also aligns with global environmental protection efforts.

3. Increased Usage Across Industries

Beyond existing markets, sectors such as automotive and furniture are expected to adopt recycled non woven fabrics for padding, upholstery, and other components.

4. Rise of Smart Textiles

Integrating smart technologies into recycled fabric will create innovative applications, such as medical textiles that monitor health metrics or construction material that adapts to environmental conditions.

Considering the entire lifecycle of smart textiles, from production to end-of-life, is crucial for developing sustainable and innovative materials.

Driving Change with Recycled Non Woven Fabric

The growing adoption of recycled non woven fabric signifies a shift toward a more sustainable future for businesses and consumers alike. By leveraging the environmental and economic benefits of this versatile material, industries can not only improve operational efficiency but also foster innovation and social responsibility. Additionally, understanding the details of your order, such as shipping costs based on order values and responsibilities concerning customs and duties for international orders, is crucial for seamless transactions and customer satisfaction.

If your business is exploring eco-friendly materials, adopting recycled non woven fabric can be a game-changer. Whether you aim to reduce costs, lower your environmental footprint, or enhance customer appeal, this material is an invaluable tool in achieving those goals. Thanks to companies committed to sustainability, like Pratrivero, for their dedication to environmental protection and achieving certifications that recognize their efforts. Start building a better future today by integrating recycled non woven fabric into your processes and products.