Thread Factory

For the past 20 years, MH has dedicated its expertise to the production of high-quality sewing thread and embroidery thread.

At present, MH boasts two industry zones dedicated to thread factories, encompassing a sprawling plant area of 150,000m2 and a workforce of over 1200 employees. With state-of-the-art machinery and a rigorous manufacturing management system in place, we take pride in delivering threads of exceptional quality and providing reliable service to our diverse clientele of 1000 customers worldwide.

We provide a wide range of options for both MH Sewing thread and embroidery thread, offering an extensive selection of 800 vibrant colors. No matter the size of your order, we are here to assist you. Simply let us know your requirements and we will guide you in selecting the perfect thread, backed by our expert advice. Our commitment to innovation drives us to not only deliver superior thread products, but also to provide an exceptional customer experience.

-

Test Center

Our test center is equipped with a comprehensive range of testing equipment. This enables us to meticulously assess and manage quality throughout the entire production process, from raw yarn to finished threads. We conduct tests for evenness, hairiness, strength, color fastness, and sewing performance. By ensuring these parameters meet our stringent standards, we deliver products of the utmost quality and reliability.

Uster Classimat

Uster Classimat

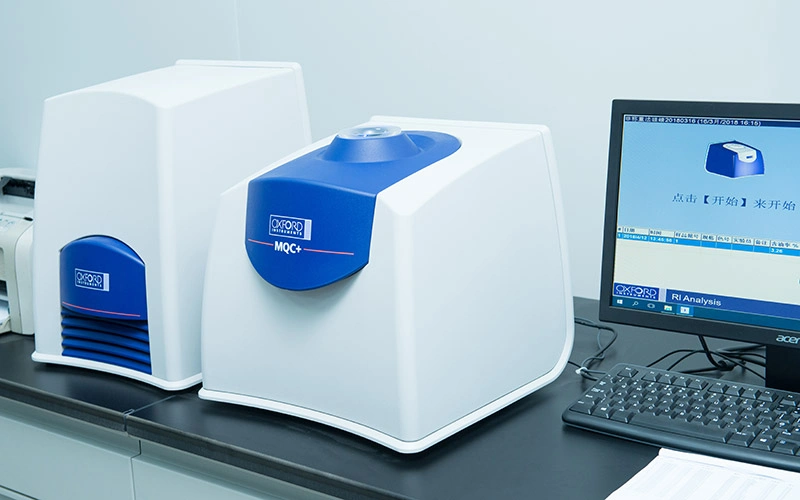

MQC+Benchtop NMP for Spin Finish

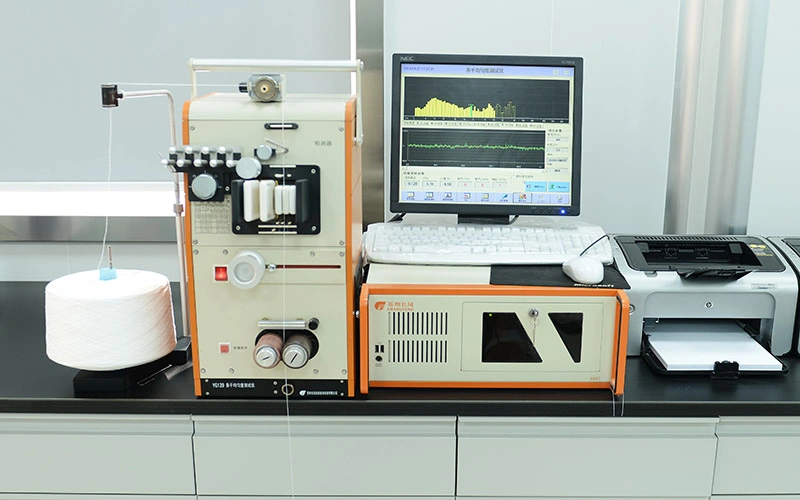

Evenness Tester

Sewing Tester

-

Color Sample Center

Our color sample center has an automatic color control system to ensure accurate color matching for our customers' needs. Our advanced production line, with strict product standards, ensures that MH thread maintains a stable, high-quality standard.

Automatic Color Control System

Automatic Color Control System

Automatic Dispensing System

-

Sewage Treatment Center

MH has an advanced sewage treatment center and water recycling system. The company is committed to energy saving, environmental protection, and green production. MH holds certificates for ISO 90001:2015, ISO14001:2015, ISO18001:2007, and Oeko-tex 100.

Sewing Thread Factory

MH Sewing Thread Factory boasts a comprehensive production process encompassing yarn spinning, dyeing, winding, and packing. With an impressive annual production capacity of 35,000 tons, we offer a diverse range of top-quality threads. Our product lineup includes spun and corespun polyesters, bonded nylon, and waxed polyester threads, available in various sizes and specifications to cater to every customer's unique requirements. Our clientele spans across global manufacturers in the clothing, bedding, carpet, home fashion, industrial, and packaging sectors, among others. Thanks to our unwavering commitment to superior quality and competitive pricing, our products enjoy widespread acclaim from customers worldwide.

-

Dyeing and Drying

In the dyeing and drying process, we prioritize both color matching and color fastness, as well as the shape of the dyed yarn spindle. The spindle's shape directly impacts the quality of thread rewinding. By ensuring the spindle has an appropriate shape, we can minimize the rate of breakage during rewinding, thus enhancing overall quality.

Fongs Dyeing Machine

Thies Pressure Dryer

-

High-speed Winding Machine

The SSM TK2-20CT high-speed precision winding machines not only ensure the thread cone is in good shape with suitable tension and has no deformation during transportation, but also have excellent performance in length and oil uniformity.

SSM TK2-20CT high-speed precision winding machines

High speed winding machine

Embroidery Thread Factory

MH Embroidery Thread Factory boasts a comprehensive array of production lines dedicated to spinning, dyeing, winding, and shaping. These cutting-edge facilities ensure the efficient and top-notch mass production of both rayon and polyester embroidery threads. With an annual production capacity of 3,500 tons, we are committed to delivering embroidery threads that embody high tenacity, minimal knots, exceptional color fastness, and a luxuriously soft touch. Our priority is to provide our customers with the finest quality threads that surpass expectations.

-

Reeling

-

Twisting

-

Skeining

-

Spray Staining

-

Drying

-

Yarn Reversing

-

Winding

-

Packaging