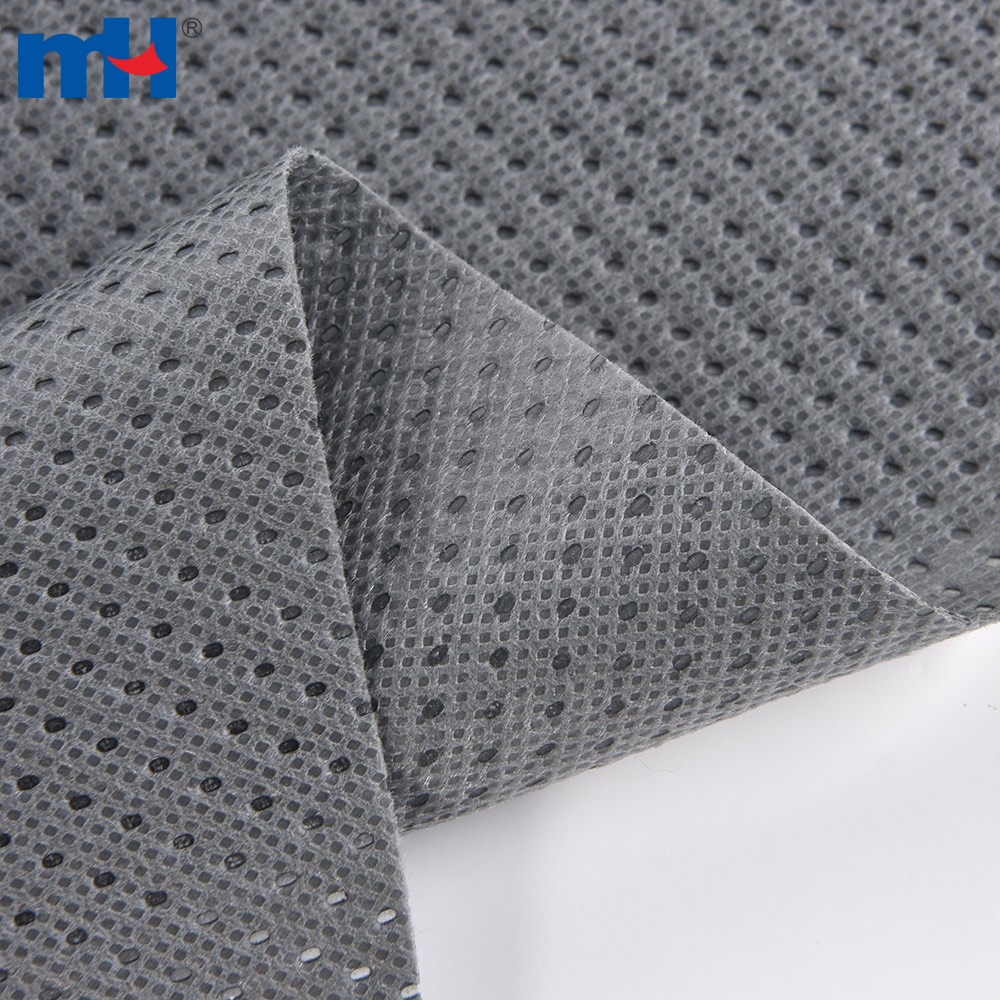

Car Cover Nonwoven Material

4 Layer Compound Nonwoven Fabric

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

MH Non-woven Interlining Factory

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Product Details

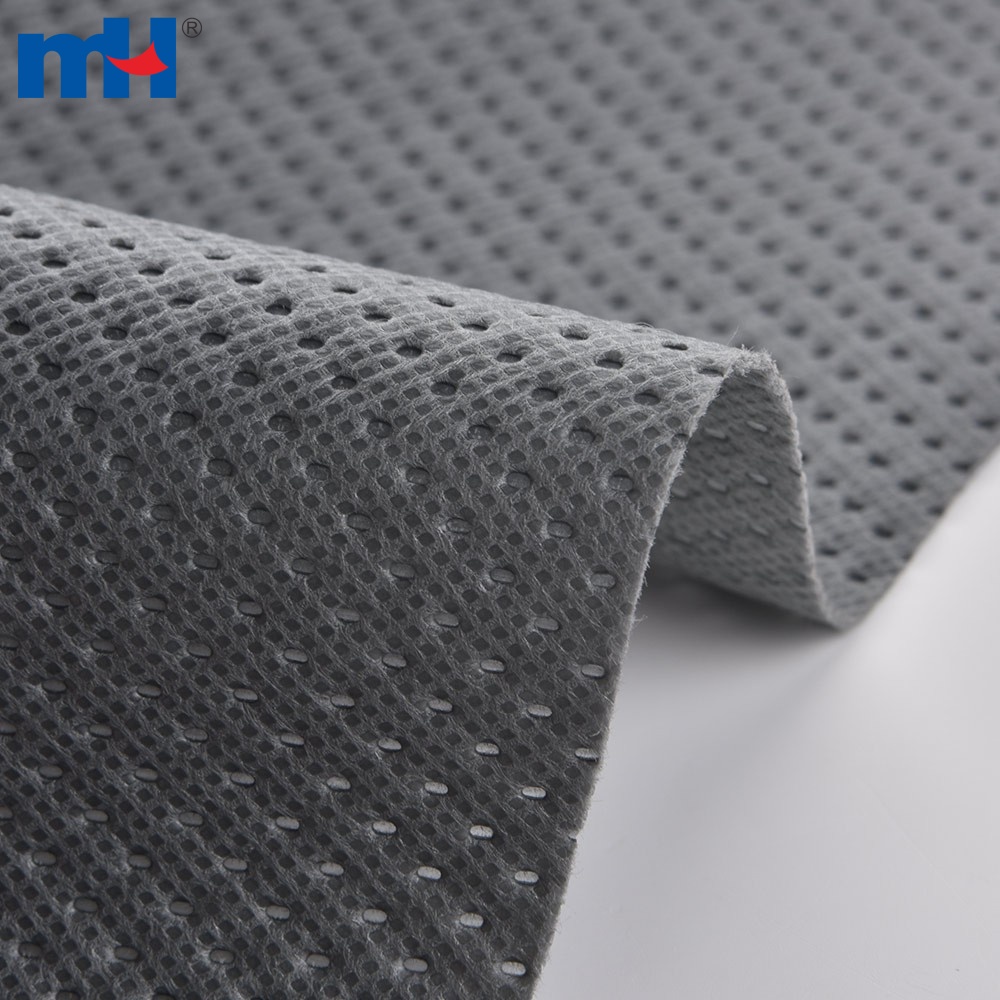

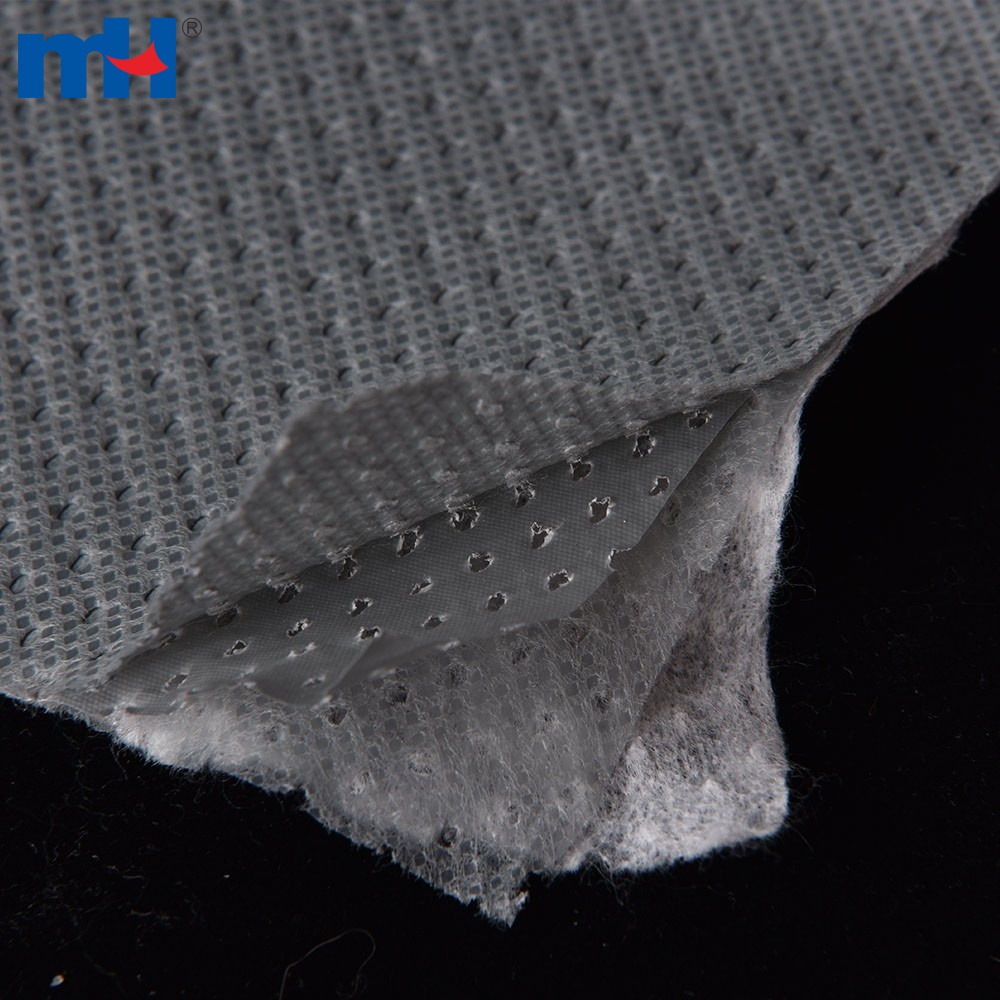

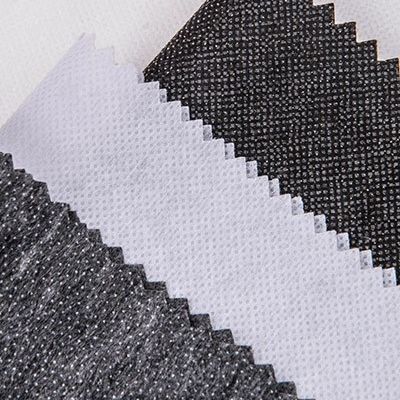

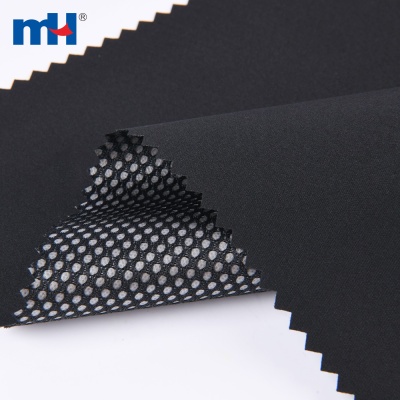

Bonded 4-layer compound Spunbond/PE Film/Spunbond/Spunbond non-woven fabric

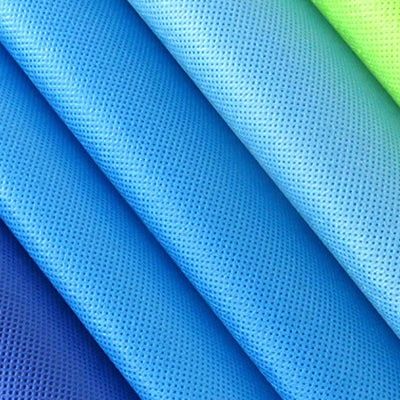

Nonwoven Technic: Laminated

Multi-layer nonwoven materials fabric is applied in car covers, motorcycle covers, and tire covers with UV resistance.

The Bonded 4-layer compound Spunbond+PE Film+Spunbond+Spunbond non-woven fabric is a multi-layer composite material that combines the functionality and performance of different layers. It is widely used in medical, hygiene, industrial, and packaging applications.

Structure Composition

First Layer: Spunbond (Non-woven Fabric)

Made of polypropylene (PP), it offers excellent strength and breathability.

Provides the base mechanical strength and support.

Second Layer: PE Film (Polyethylene Film)

A waterproof and impermeable layer made of polyethylene.

Acts as a barrier against water and liquids while maintaining flexibility.

Third Layer: Spunbond (Non-woven Fabric)

The middle spunbond layer enhances the overall strength and durability of the material.

Adds extra support and stability.

Fourth Layer: Spunbond (Non-woven Fabric)

The outermost spunbond layer improves abrasion resistance and provides a soft touch.

Suitable for direct skin contact.

Key Features

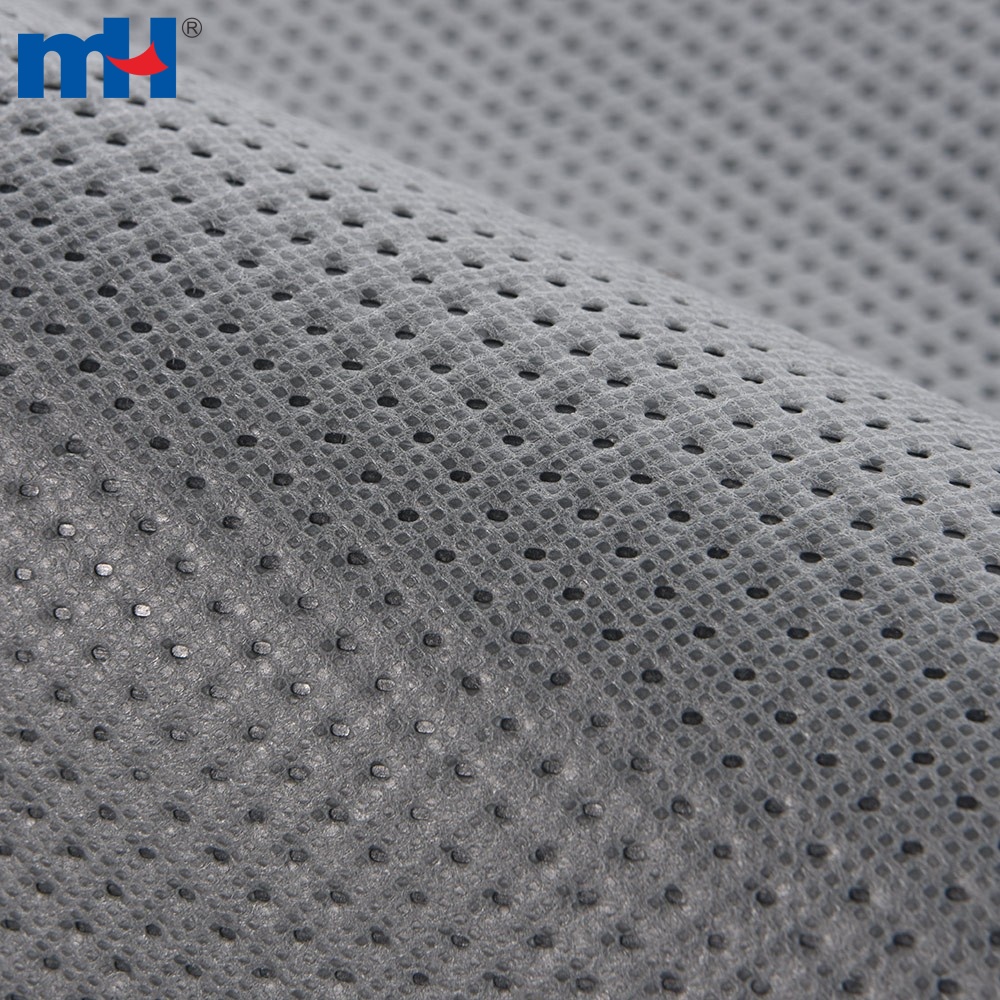

- High Strength and Durability: The multi-layer structure ensures excellent tensile strength and tear resistance.

- Waterproof: The PE film layer provides effective waterproofing and liquid barrier properties.

- Breathability: Despite the waterproof layer, the spunbond fabric allows for air permeability, ensuring comfort during use.

- Softness: The outer spunbond layer is soft to the touch, making it ideal for skin contact.

- Versatility: Suitable for a wide range of applications, including medical protective clothing, surgical drapes, hygiene products (e.g., diapers, sanitary pads), and industrial packaging.

Usage

- Medical Field: Used in surgical gowns, isolation gowns, protective clothing, and more, offering both protection and comfort.

- Hygiene Products: Ideal for baby diapers, adult care products, sanitary napkins, providing absorbency, leak protection, and softness.

- Industrial Packaging: Used as waterproof and dustproof packaging materials.

- Construction: Serves as waterproof and moisture-resistant building materials.