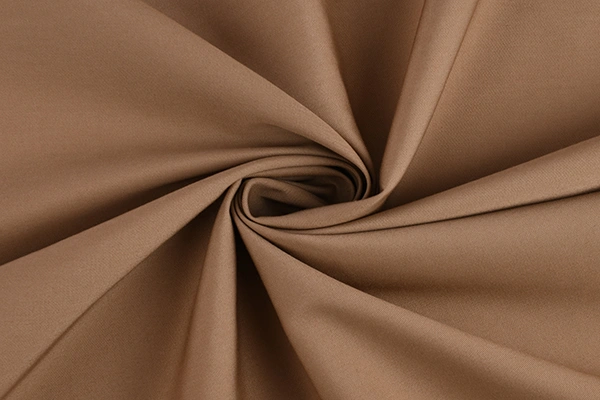

TR Suiting Fabric

Material: Polyester, Viscose

Spec: T/R 80/20, T/R 85/15, T/R 90/10

Weight: Customized

Width: 57/58"

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

TR Uniform Fabric

Woven Fabric Factory

MH operates more than 40+ branches across 35 countries worldwide. We have a dedicated team of over 100 local staff who personally visit customers, ensuring seamless service delivery on behalf of MH. With just one call, or even without a call, as our staff regularly visit customers, our local team is always ready to provide assistance. Effective communication in the local language further enhances the smooth exchange of information, making it more convenient for everyone involved.

-

Direct-to-Client Services

Direct-to-Client Services -

Prompt Response without Time Zone Delays

Prompt Response without Time Zone Delays -

Effective Communication in Local Language

Effective Communication in Local Language

Customization Services

Material Customization

Width Customization

Specification Customization

| Specification | Dyeing process |

| TR 80/20 32S*32S 130*70 160GSM 57/58" | Beck Dye |

| TR 85/15 32S*32S 133*72 165GSM57/58" | Beck Dye |

| TR 85/15 32*32 133*72 170GSM 57/58" | Beck Dye |

| TR 85/15 32S*32S 133*72 165GSM57/58" | Continue Dye |

| TR 85/15 32*32 133*72 170GSM 57/58" | Continue Dye |

| TR 80/20 32S/2*32S/2 56*48 175GSM 57/58" fabric hem with english letters pattern |

Beck Dye |

| TR 80/20 32S/2*16S 56*48 175GSM 57/58" fabric hem with english letters pattern |

Beck Dye |

| TR 85/15 31S*31S 102*68 136GSM 57/58" | Beck Dye |

| TR 80/20 31S*31S 84*76 125GSM 57/58" | Beck Dye |

| TR 80/20 31S*31S 104*70 140GSM 57/58" fabric hem with english letters pattern |

Beck Dye |

| TR 85/15 21*21 102*52 185GSM 57/58" | Beck Dye |

| TR 80/20 21S*21S 104*74 210GSM 57/58" | Beck Dye |

| TR 80/20 21S*21S 100*84 225GSM 57/58" | Beck Dye |

Color Customization

Packing Customization

Product Description

| Name | T/R Fabric |

| Material | Polyester, Viscose |

| Spec | T/R 80/20 T/R 85/15 T/R 90/10 |

| Weight | Customized |

| Width | 57/58" |

| Color | As attached or customized as request |

| Usage | Mainly used as garment fabric, especially for trousers, workwear, uniform |

| MOQ | 1500m/color |

| Packing | 30yds/roll,150yds/package, or 300yds/package |

| Delivery time | 20~40days after confirmed deposit |

Advantage

STABLE COLOR DIFFERENCE FOR EACH DYEVAT

LOW DEFECT RATE

FAST DELIVERY

TR FABRIC (Terylene Rayon Fabric) 133*72

Specs: T/R 80/20, 32S*32S, 133*72, 170GSM, 57/58”

MOQ: 5000m/color

Packaging: in roll or half fold in bale

QTY: 81750yds/20GP (shrunk half fold in bale)

Main fabric composition: TR 85/15, 80/20, 65/35

Product Features

Durable

Made of superior yarn, TR fabric is soft and not easy deformed.

Clear Texture

Bright glamorous color and clear texture, looks great.

Comfortable to Wear

TR fabric is soft, eco-friendly, and not easy to wrinkle, with excellent drape, easy to clean and dry quickly.

TR FABRIC (Terylene Rayon Fabric) 56*48

TR fabric is polyester and rayon blended fabric, so it has the advantages of polyester and rayon. TR fabric similar like polyester fabric, it’s durable, wearable, anti-wrinkle and stable in size. With the blended rayon fiber, the TR fabric also has the feature of breathable, anti-static, and anti-pilling, and it also has a higher melting point.

Specs: T/R 80/20, 32S/2*32S/2, 56*48, 175GSM, 57/58”

MOQ: 1500m/color

Packaging: in roll or half fold in bale

QTY: 75000yds/20GP (shrunk half fold in bale)

Main fabric composition: TR 85/15, 80/20, 65/35

Product Features

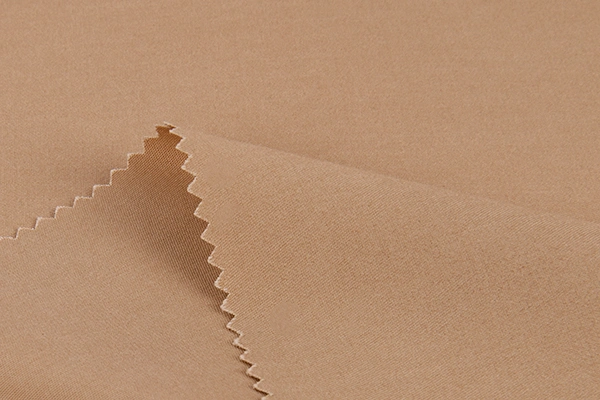

Guaranteed Quality

TR fabric is flat and stable in size. The Customized edge has neat and straight seam and hem.

Clear Texture

Bright color and clear texture, looks great.

Durable

TR fabric is soft, washable, wearable and not easy to fade.

Packing

Factory introduction

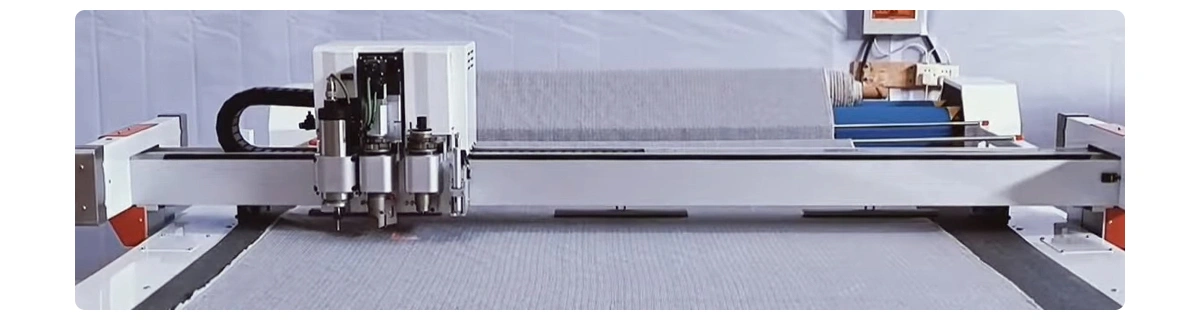

Weaving

MH’s products are made by China’s advanced air jet non-shuttle looms, which not only improve production efficiency, but cut cost and save energy as well. Besides, finished fabric has few thread residues, and are tidy, flat.

Dyeing

The grey fabric are dyed by automatic temperature control systems and high-temperature high-pressure dyeing equipments. Finished fabric have even surface, bright color and excellent color fastness, and the color difference meet Europe standard.

High temperature setting

Imported setting machines help fabrics dry quickly, keeping them flat, even, and stable in width.

Fabric inspection

During producing, inspection process is in each process, from raw yarn, grey fabric, to dyed and finished fabric, only the qualified fabric which meet Europe standard can be shipped out to customers.

Other Fabric Products

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Exhibition

Global Textile Excellence, Showcasing Worldwide.

MH at Leading Industry Exhibitions: Pioneering innovation, sustainability, and global collaboration.

Crafting the Future of Textiles—Join Us Across Continents.

Shipping Methods