Hot Melt LFC Zipper Solutions for Modern Zip Screen Systems

With the rapid growth of motorized zip screens and smart roller blind systems, manufacturers are increasingly looking for sewing-free, durable, and stable zipper solutions that ensure smooth operation and long-term performance.

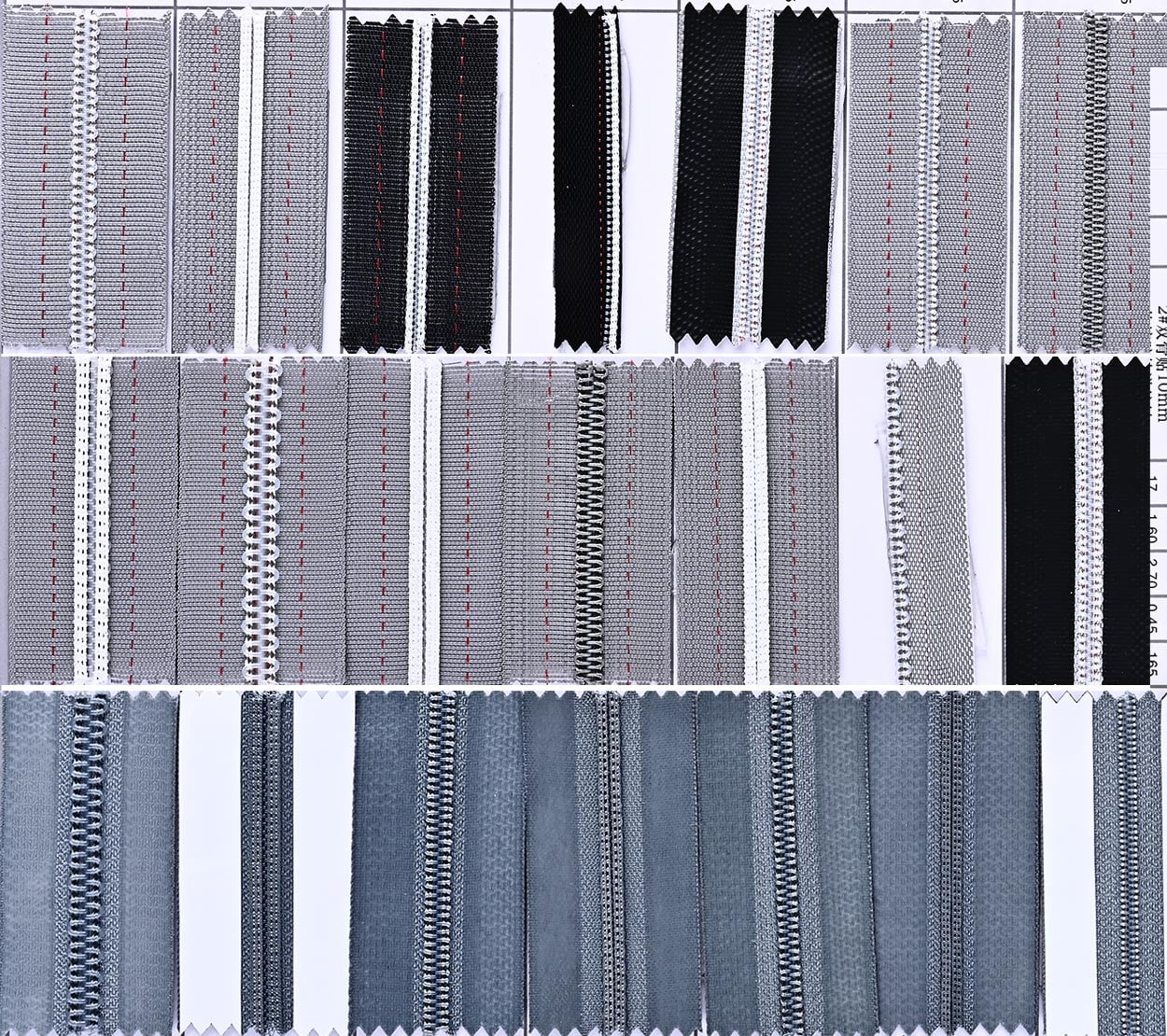

Hot Melt LFC zipper tape and hot melt film LFC zipper long chain are developed specifically for zip screen side-seal systems, offering strong heat-weld bonding, excellent durability, and compatibility with a wide range of screen fabrics.

What Is Hot Melt Adhesive LFC Zipper Technology?

Hot Melt LFC zippers are made with thermoplastic hot melt materials integrated into the zipper tape or applied as a hot melt film layer. The hot melt adhesive, sometimes referred to as glue, is applied using specialized equipment such as glue bead guns. When heated to around 165°C, the hot melt layer softens and bonds directly to the screen fabric through heat pressing, then solidifies after cooling—without sewing. Hot melt adhesives are primarily composed of thermoplastic polymers and are solid at room temperature. Using hot melt adhesives reduces the need for water and organic solvents in the production process.

This technology enables:

- Faster and cleaner production

- Consistent bonding quality

- Reliable performance in motorized zip screen systems

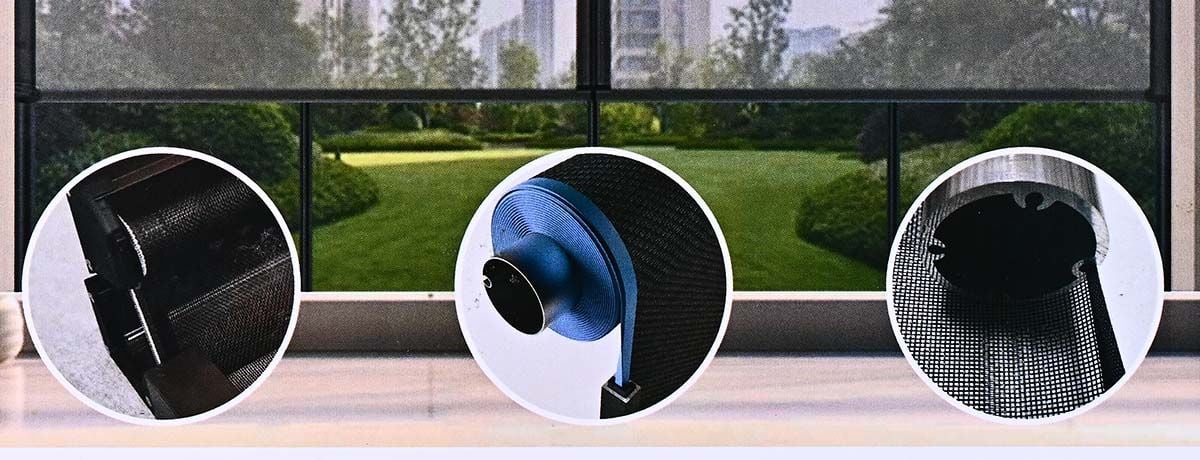

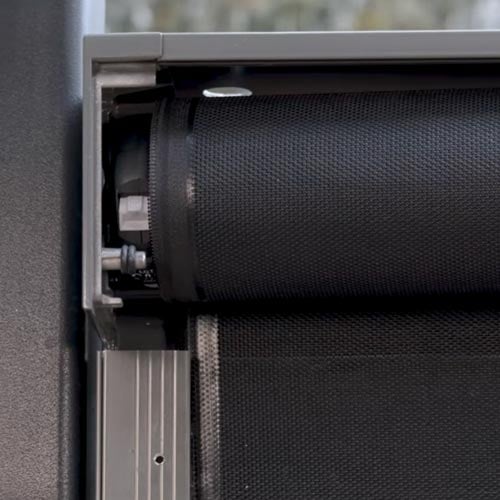

How Welded Zippers Work in Zip Screen Systems

In a typical zip screen application, half of the zipper tape is heat-welded onto each side of the screen fabric.

Once installed, the zipper edges run smoothly inside the side tracks, creating a tight seal that:

- Keeps the screen flat and wrinkle-free

- Improves side sealing and reduces light gaps

- Enhances wind resistance and fabric stability

- Ensures smooth and quiet motorized operation

Product Options: LFC Zipper Tape vs. Hot Melt Film LFC Long Chain

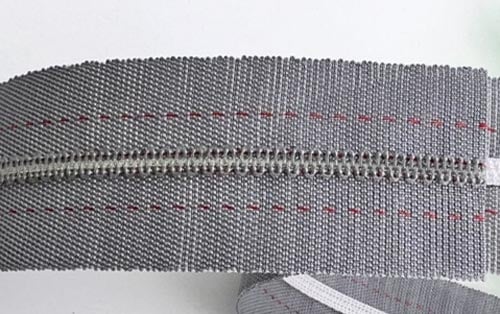

Hot Melt LFC Zipper Tape

This version uses hot-melt polyester yarns woven into the zipper tape, providing stable bonding and reinforced structure.

Key advantages:

- Heat-activated bonding at ~165°C

- Reinforced tape for wear resistance and tensile strength

- Fire-resistant, cold-resistant, and aging-resistant

- Optional light-blocking treatment on one side

Common applications:

Smart shading roller blinds, zip screen systems, architectural sunshade installations.

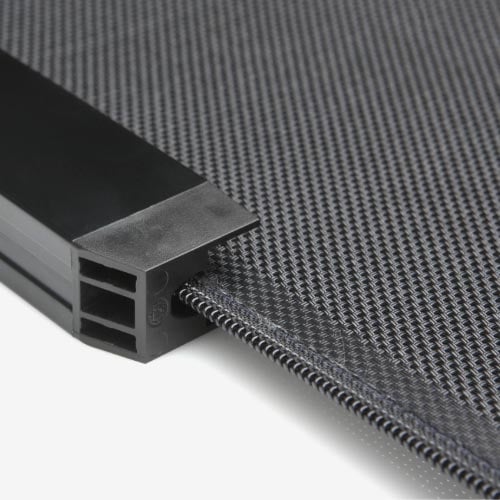

Hot Melt Film LFC Zipper Long Chain

This upgraded version adds a hot melt film layer, allowing direct heat pressing with higher efficiency.

Key advantages:

- Sewing-free installation

- Strong and uniform bonding

- Durable zipper teeth for repeated rolling

- Tooth options: exposed, semi-exposed, or covered

Best suited for:

Motorized zip screens, hot melt track systems, and screen fabrics containing PVC components.

Fabric Compatibility

Hot Melt LFC zipper solutions can be welded to a wide range of technical fabrics, including:

- Polyester screen fabrics

- PVC-coated mesh fabrics

- Sunscreen and shading textiles

- Insect screen meshes

This flexibility makes them ideal for different zip screen designs and market requirements.

Quality & Certification

The hot melt LFC zipper products are SGS tested, including:

-

Tensile strength before aging

-

Tensile strength after aging

-

Appearance inspection after aging

The test results confirm stable mechanical performance and excellent aging resistance, suitable for long-term use in motorized zip screen systems.

In addition, the materials are OEKO-TEX® certified, ensuring compliance with international textile safety standards.

Applications and Industries

The Hot Melt Film LFC zipper long chain stands out as a versatile solution across a wide spectrum of industries, thanks to its innovative combination of zipper functionality and hot melt adhesive technology. Designed for high temperature environments, this product details a self-adhesive feature that eliminates the need for sewing, streamlining production and enhancing efficiency in various manufacturing settings.

In the textile industry, the Hot Melt Film LFC zipper long chain is a game-changer for clothing, bags, and other fabric items. The hot melt adhesive applied to the zipper tape creates a strong, reliable bond, ensuring that the zipper remains securely attached even under stress or frequent use. This makes it especially valuable for outdoor gear, work uniforms, and other products that demand durability and long-lasting performance.

Automotive manufacturers also benefit from this advanced zipper solution. The high temperature resistance and robust adhesive make it ideal for use in car upholstery, covers, and interior accessories where a secure, seamless fastening system is essential. The ability to customize the zipper’s color, size, and design ensures a perfect match for any automotive interior, supporting both functional and aesthetic requirements.

Furniture production is another area where the Hot Melt Film LFC zipper long chain excels. Upholstered furniture often requires a fastening method that is both strong and discreet. The hot melt adhesive technology allows for a clean, invisible finish without visible stitching, enhancing the overall design and appeal of the finished item.

For customers, every item is carefully packed to prevent damage during shipping, and a clear refund policy is in place to ensure satisfaction if the product does not meet expectations. Paid shipping options are available for added convenience, and buyers can leave reviews to share their experiences and help others make informed decisions. Each product comes with a unique code and detailed design specifications, making it easy to order the exact item needed for any project.

The Hot Melt Film LFC zipper long chain is available in a wide variety of sizes and customization options, catering to both low-volume orders for small businesses and large-scale industrial requirements. Whether you need a quick quote for a small batch or are placing a bulk order for a major production run, this product offers the flexibility and reliability to meet your needs.

Thanks to the hot melt adhesive technology, production time is significantly reduced, as there is no need for sewing or other time-consuming attachment methods. This makes the Hot Melt Film LFC zipper long chain an ideal choice for businesses with tight deadlines or those requiring rapid prototyping and fast turnaround.

In summary, the Hot Melt Film LFC zipper long chain delivers exceptional convenience, durability, and design flexibility. Its applications span textiles, automotive, and furniture manufacturing, making it a valuable product for a wide range of industries seeking efficient, high-quality zipper solutions.

Why Hot Melt LFC Zippers Are Widely Used

For zip screen manufacturers and system integrators, these zipper solutions offer:

-

Consistent quality for mass production

-

Reduced installation time and labor cost

-

Reliable performance in outdoor environments

-

Easier compliance with international market requirements

They are widely used in Europe, the Middle East, North America, South America, and other global markets where durable and high-performance zip screen systems are required.

Conclusion

Hot Melt LFC zipper tape and hot melt film LFC zipper long chain provide a professional, sewing-free solution for modern zip screen and motorized roller blind systems.

With strong heat-weld bonding, certified durability, and broad fabric compatibility, they help ensure flat screens, smooth operation, and long service life in demanding outdoor applications.