Bulky Nylon Thread: Essential Guide for Wholesale Operations

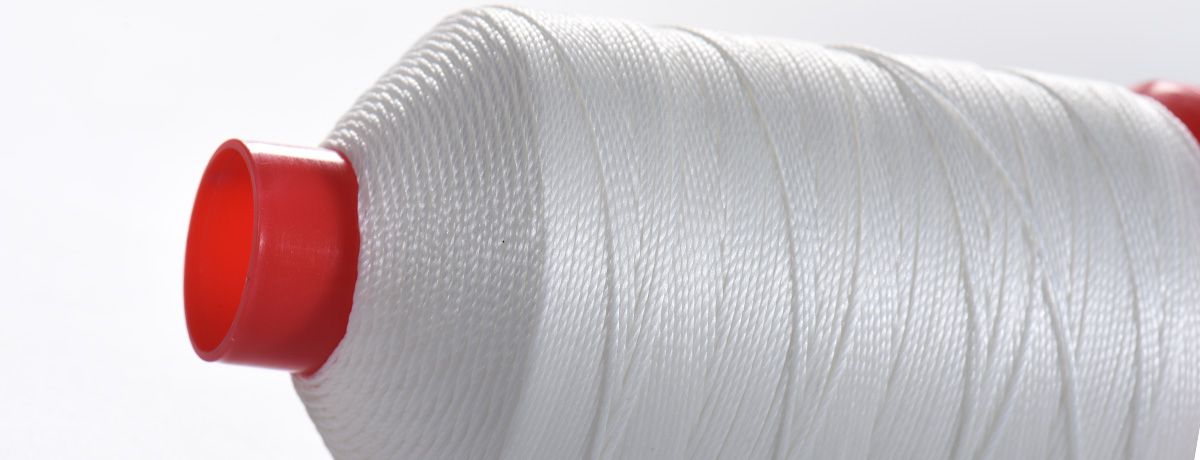

Bulky nylon thread represents a specialized textile solution designed for professional sewing and serger applications. This versatile material delivers superior performance across multiple fabric types, making it an essential component for wholesale textile operations. Understanding its properties, applications, and optimal usage techniques enables businesses to maximize operational efficiency and product quality.

Understanding Bulky Nylon Thread Properties

Bulky nylon thread features enhanced thickness compared to standard nylon varieties, providing increased durability and coverage. The material maintains excellent elasticity while offering superior strength retention under stress. These characteristics make it particularly suitable for applications requiring robust seam construction and long-term performance.

The thread's synthetic composition ensures consistent color retention and resistance to common textile degradation factors. Unlike natural fiber alternatives, bulky nylon thread maintains its structural integrity across varying environmental conditions, making it ideal for commercial production environments.

Primary Applications for Professional Use

Swimwear and Athletic Apparel

Bulky nylon thread excels in swimwear construction due to its resistance to chlorine and saltwater exposure. The material's flexibility accommodates the stretch requirements of athletic fabrics while maintaining seam integrity during extended use. Professional manufacturers utilize this thread for both decorative and functional seaming applications.

Undergarments and Intimate Apparel

The soft finish of bulky nylon thread makes it optimal for undergarment construction where skin contact requires comfort considerations. Its ability to create flat, non-irritating seams enhances the end-user experience while providing the durability necessary for frequent washing cycles.

Knitwear and Stretch Fabrics Seams

Knitwear applications benefit from bulky nylon thread's ability to accommodate fabric stretch without compromising seam stability. The thread moves with the fabric during wear, preventing seam failure and maintaining garment shape over time.

Technical Specifications and Compatibility

Bulky nylon thread operates effectively with universal needle sizes ranging from 70/10 to 80/12. This compatibility range accommodates various fabric weights from light to medium-heavy materials. The thread functions optimally with all standard overlock machines and sergers, ensuring broad equipment compatibility across production facilities.

Machine compatibility extends to walking foot applications, where the thread's properties enhance feed consistency and stitch formation. Proper tension adjustment ensures optimal thread performance and reduces production interruptions.

Implementation Best Practices

Serger Machine Setup and Preparation

Proper machine setup begins with thread path verification to prevent tangling and ensure consistent feed. Maintaining appropriate thread tension prevents both loose stitching and excessive thread breakage. Test seaming on sample materials confirms optimal settings before full production runs.

Care and Handling Specifications

Bulky nylon thread requires specific care protocols to maintain its performance characteristics. Low-temperature ironing prevents thread degradation while preserving seam appearance. Non-chlorine bleach compatibility allows for standard commercial laundering processes without thread damage.

Storage conditions should protect the thread from excessive heat and direct sunlight exposure. Proper inventory rotation ensures optimal thread performance across all production batches.

Wholesale Operations and Logistics

Wholesale operations at leading suppliers such as www.thethreadexchange.com and www.wawak.com are designed with both security and efficiency in mind. Before proceeding with any order, users are guided through a verification process that confirms they are human, not automated bots. This security review, which may include a brief verification successful waiting period and the assignment of a unique ray id, ensures a secure connection for all transactions and protects the integrity of the wholesale platform.

Once verification is complete, users can seamlessly continue with their wholesale actions—responding to price quotes, reviewing available items, and sorting products by price, date, or other relevant factors. This streamlined process allows buyers to quickly find the perfect serger threads for their work, whether they are completing seams on swimwear, hemming knitwear, or tackling other professional sewing projects.

Logistics teams at these wholesale sites take special care in storing items to prevent any damage to the edges of the threads, ensuring that every spool arrives in perfect condition for hemming, serging, or other sewing tasks. For those who need to iron their finished products, detailed care instructions are provided, recommending low temperature settings to maintain the integrity of the nylon thread.

The platforms also offer a wide selection of sep (separate) threads, allowing users to order specific colors or types—such as the popular Hydrangea thread from Gütermann—to match their unique project requirements. With efficient order processing and prompt shipping, the logistics team works diligently to minimize any verification successful waiting time, so users can continue their work without unnecessary delays.

By prioritizing security through human verification and providing a robust, user-friendly ordering system, www.thethreadexchange.com and www.wawak.com ensure that wholesale operations run smoothly. This allows textile professionals to find, review, and order the ideal threads for their needs, confident in the knowledge that their connection is secure and their items will arrive ready for action—whether for swimwear, knitwear, or any other sewing application.

Operational Advantages for Wholesale Operations

Production Efficiency

The thread's reliability reduces machine downtime and rework requirements, directly impacting production throughput. Its compatibility with multiple fabric types allows for streamlined inventory management and reduced SKU complexity.

Quality Assurance

Consistent stitch formation and seam durability reduce quality control rejections and warranty claims. The thread's performance predictability enables accurate production planning and delivery scheduling.

Price and Cost Optimization

Reduced thread breakage minimizes production interruptions and material waste. The thread's versatility across multiple applications consolidates purchasing requirements and reduces inventory carrying costs.

Making the Right Choice for Your Operations

Bulky nylon thread serves as a strategic textile component for wholesale operations requiring reliable, high-performance sewing solutions. Its technical properties align with professional production requirements while delivering consistent results across diverse applications.

Successful implementation requires attention to machine compatibility, proper handling procedures, and appropriate storage conditions. These factors combine to maximize the thread's performance potential and operational value.

Wholesale textile operations benefit from incorporating bulky nylon thread into their standard material specifications, particularly for applications involving stretch fabrics, swimwear, and undergarments. The material's proven performance characteristics and broad compatibility make it an essential component for professional textile manufacturing.

Contact MH

MH offers bulky nylon threads. Please contact us for more details or inquiries. We're here to help!