How Does Coated Taffeta for Bag Lining Perform in Outdoor and Industrial Environments?

Introduction

In the bag manufacturing industry, internal materials are selected based on function, durability, and long-term performance rather than appearance alone. For backpacks, travel bags, tool bags, tents, umbrellas, and other outdoor products, water resistance and strength are essential requirements.

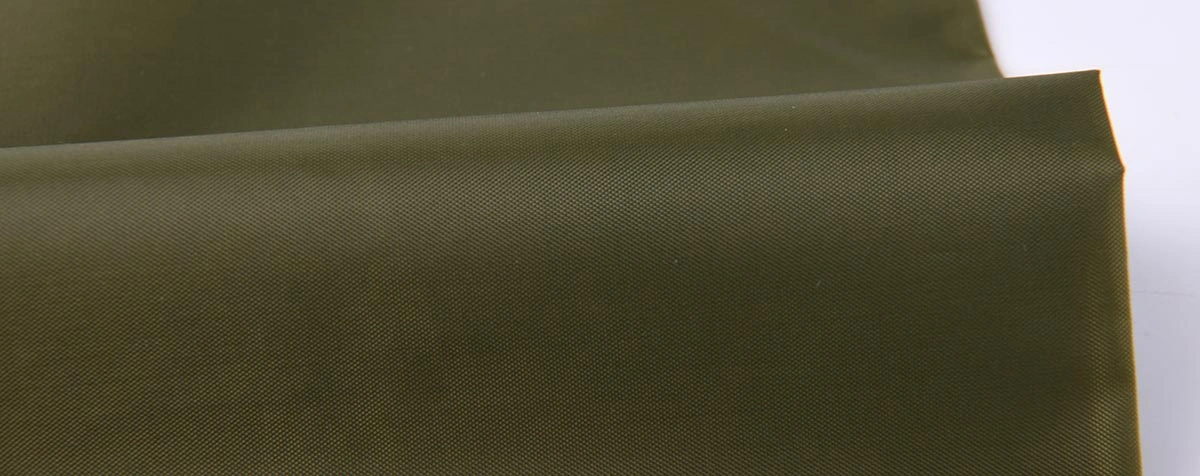

Coated taffeta for bag lining is widely used in these applications. Produced as a polyester fabric with functional coatings, coated taffeta provides a smooth lining surface, reliable waterproof performance, and consistent quality for bulk production. For industrial buyers, this material offers a practical balance between weight, durability, and value.

What Is Coated Taffeta Fabric?

Coated taffeta fabric is based on plain woven taffeta, typically made from 100% polyester fibers or, in some cases, nylon taffeta for specific requirements. Taffeta is a crisp, smooth, and slightly stiff woven fabric.

The fabric consists of polyester stiff net mesh fabric designed for hats and caps.

-

A woven taffeta base that provides strength and structure

-

A functional coating layer that enhances water resistance. A tight weave (high thread count per square inch) ensures better water resistance and durability.

Polyester taffeta fabric is lightweight and has a shiny appearance.

It is important to understand details such as weight, weave pattern, and finishes to ensure the fabric matches the intended use and desired quality. For a comprehensive introduction, check out this beginner's guide to sewing and textiles.

Compared with uncoated taffeta lining fabric, coated taffeta is designed specifically for outdoor applications and bag interiors, where protection against moisture is required.

Polyester Taffeta vs Nylon Taffeta for Bag Lining

Both polyester taffeta and nylon taffeta are used in bag manufacturing, but they serve different purposes.

-

Better cost control for bulk buyers

-

Stable supply and consistent quality

-

Good strength and durability

-

Suitable for most bag lining applications

-

Slightly lighter weight

-

Higher cost

-

Commonly used in garment applications such as jackets and sportswear, as well as tents and purses, due to its versatility and weather-resistant qualities

-

Nylon variants of coated taffeta offer particularly high tear strength, making them suitable for demanding applications

For most industrial buyers, polyester taffeta remains the preferred choice due to its balance of performance, price, and availability.

Water Resistance for Outdoor Applications

Water resistance is a key attribute of coated taffeta fabric.

In real-world use, coated taffeta lining helps:

-

Protect items stored inside bags

-

Prevent moisture penetration during rain

-

Reduce water absorption in outdoor environments

-

Improve product reliability for end users

This makes coated taffeta suitable not only for bags, but also for umbrellas, tents, and other outdoor fabric applications where internal waterproof layers are required.

Typical Uses of Coated Taffeta Fabric

Coated taffeta fabric is widely used across multiple product categories, including:

-

Bag lining for backpacks and travel bags

-

Inner layers of tool bags and equipment bags

-

Outdoor storage bags

-

Umbrella and tent lining

-

Functional inner linings for industrial products

Although taffeta is sometimes associated with garments such as jackets or sportswear, in coated form it is primarily selected for functional lining purposes rather than fashion design.

Weight, Strength & Performance Balance

Selecting the correct weight is essential when choosing coated taffeta for bag lining. Coated taffeta remains very light despite its functional benefits, making it ideal for applications that require minimizing weight. It is a very lightweight fabric, adding minimal bulk to the bag.

Manufacturers typically consider:

-

Required waterproof performance

-

Desired fabric strength and toughness

-

Flexibility and ease of sewing

-

Overall product weight

Weight impacts durability and feel; lighter weights are suitable for general-purpose bags, while medium to heavy weights are better for more durable applications. 190t taffeta bag lining fabric is lightweight, making it simple to handle and ship.

Coated taffeta offers a wide range of options, including different sizes to meet diverse customer needs, allowing buyers to adjust specifications to meet different project needs while maintaining consistent performance.

Color Variety & Appearance

Coated taffeta fabric is available in a variety of colors, including bright colors and neutral shades commonly used for bag interiors.

Benefits include:

-

Stable color performance

-

Consistent coating adhesion

-

Clean and smooth lining appearance

Color consistency is particularly important for buyers managing long-term production programs and repeat orders.

Durability, Washing & Maintenance

For industrial and outdoor use, durability is a critical factor.

Polyester coated taffeta fabric offers:

-

Good tear and abrasion resistance. Coated taffeta is resistant to tearing and abrasion, ensuring the lining withstands repeated use.

-

Stable performance after washing. The sealed or sleek coated surface is often stain-resistant and can be wiped clean with mild soap and water.

-

Suitable care under low heat or cold water. Coated taffeta fabric is easy to care for, typically requiring a gentle machine wash in cold water and low-temperature drying. Avoid high heat when you wash to maintain the fabric's integrity and longevity.

-

Long service life in tough environments

These attributes help reduce product returns and improve overall value for buyers.

Bulk Supply, Rolls & Industrial Ordering

Coated taffeta fabric is supplied primarily for bulk and industrial use, not retail purchase.

Typical supply conditions include:

-

Fabric supplied in rolls

-

Stable quality across production batches

-

Efficient packing for shipping

-

Suitable for long-term supply agreements

Buyers can order coated taffeta fabric according to project timelines, production schedules, and monthly requirements.

MH as a Supplier of Coated Taffeta Fabric

As an experienced supplier based in China, with production and sourcing capabilities in Zhejiang, MH supplies coated taffeta fabric for bag lining and outdoor applications. MH offers polyester taffeta fabric with PU or PVC coatings, designed to meet the performance requirements of industrial buyers.

MH supports:

-

Bulk supply in rolls

-

Multiple fabric weights and coating types

-

Stable quality for repeat orders

-

Custom colors and specifications based on buyer needs

With years of experience serving international markets, MH focuses on industrial and wholesale supply, helping buyers select suitable coated taffeta fabrics that meet strength, durability, and water resistance requirements.

How Buyers Select the Right Coated Taffeta Fabric

When selecting coated taffeta fabric, buyers typically evaluate:

-

End-use purpose

-

Required water resistance level

-

Fabric weight and strength

-

Color and appearance

-

Supply stability and lead time

This section provides answers to common questions about types of polyester products available, how to select trustworthy suppliers, and methods for assessing fabric quality.

Polyester taffeta is the most common and cost-effective option, offering good durability and wrinkle resistance.

Choosing the right supplier ensures that fabric attributes remain consistent across different production runs.

Conclusion

Coated taffeta fabric for bag lining is a strong, durable, and water-resistant material suitable for outdoor and industrial applications. Made primarily from 100% polyester fibers, it provides reliable performance, long service life, and excellent value for bulk buyers.

For manufacturers and buyers seeking a dependable lining solution for bags, umbrellas, tents, and similar products, coated polyester taffeta remains a proven and practical choice—especially when sourced from experienced suppliers such as MH.