The Best Needle for Embroidery Machine: Tips for Perfect Stitches

Choosing the right needle for embroidery machine is essential for perfect stitches. This article will guide you through the types of embroidery needles, their features, and how to pick the best one based on your project’s needs.

Key Takeaways

-

Selecting the appropriate needle for machine embroidery is crucial for achieving high-quality stitches, considering factors such as machine specifications, fabric type, and thread.

-

Different needle types, such as universal, ballpoint, and sharp point needles, are tailored for specific fabrics and embroidery techniques, enhancing performance and avoiding thread breakage.

-

Regular maintenance, including timely needle replacement and proper storage, is essential to sustaining needle effectiveness and ensuring flawless embroidery results.

Understanding Machine Embroidery Needles

Choosing the right needle is key to achieving high-quality results in machine embroidery projects. The performance of your embroidery machine hinges on this small yet vital component. Key factors influencing needle selection include:

-

The specifications of your embroidery machine

-

The type of fabric you are working with

-

The stabilizer

-

The thread type

Knowing the differences between machine embroidery needles and standard sewing machine needles ensures you select the correct size and type for your projects. Before buying embroidery needles, always review the user manual of your embroidery machine to ensure compatibility. Understanding these basics sets the foundation for more advanced knowledge about needle selection and usage.

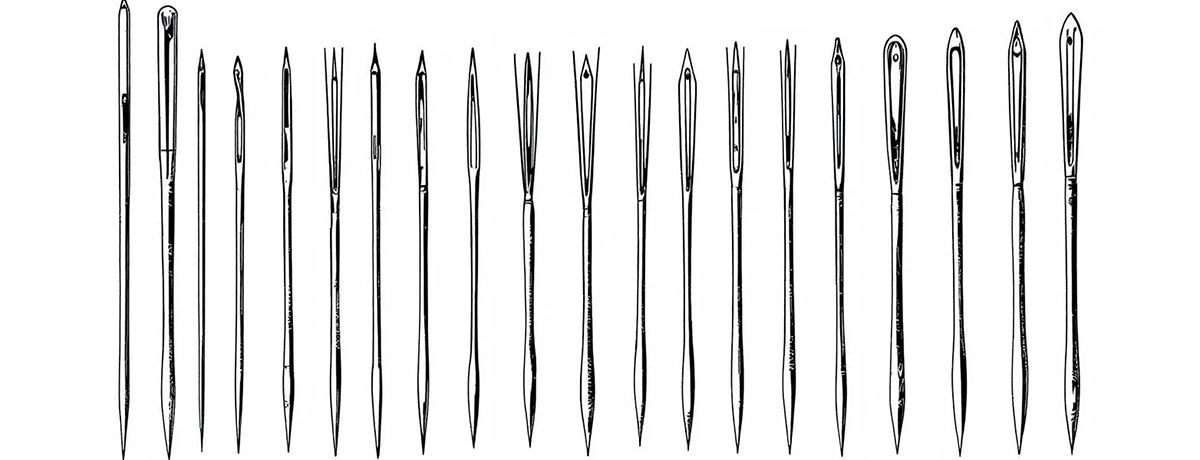

Anatomy of an Embroidery Needle

An embroidery needle consists of several main parts, including:

-

Shank: the top part that fits into the machine, with a flat side and a round side crucial for proper fitting

-

Shaft

-

Groove

-

Eye

-

Scarf

-

Point

The shank’s design ensures that the needle stays securely in place during the stitching process.

Most embroidery needles feature a universal point, which has a slightly rounded tip. This design helps prevent damage to the fabric and ensures smooth stitching. Knowing these components aids in choosing the right needle for your projects, leading to optimal performance and beautiful results.

Differences Between Embroidery Needles and Sewing Machine Needles

Embroidery needles differ from sewing machine needles mainly in the shape of their eye and scarf. The larger eye of embroidery needles reduces friction and accommodates delicate threads without breakage. This feature is essential for maintaining the integrity of metallic threads and other sensitive materials.

The scarf on the back of the embroidery needle is specially designed to allow the bobbin casing to get close enough to the eye to catch the thread and create a stitch effectively. This design difference ensures smoother thread passage and reduces the chances of thread breakage, making embroidery needles more suitable for intricate designs compared to standard sewing needles.

Choosing the Right Needle Size

Selecting the correct needle size is crucial for high-quality embroidery, as it directly impacts stitching performance. The needle size you select influences stitch quality and helps prevent common issues such as skipped stitches and thread breakage. When choosing needles for machine embroidery, consider factors like:

-

Fabric

-

Stabilizer

-

Thread

-

Stitch density

Needle sizes should correspond with both fabric weight and the type of stabilizer and thread. Embroidery needles typically range in size from 7-11 (US) or 70-110 mm, with smaller needles suitable for lighter fabrics.

For embroidery projects, using sewing machine needles typically requires going up a size from the standard embroidery needle.

Common Needle Sizes and Their Uses

Common needle sizes include size 75/11 for lightweight fabrics and size 90/14 for medium-weight fabrics. The eye of an embroidery needle is larger and designed specifically to accommodate thicker embroidery threads, which is essential for ensuring smooth stitching in various fabrics. When choosing needle size, consider factors such as fabric weight to avoid creating unnecessary holes.

Always keep a variety of needles on hand and conduct a test run before starting embroidery projects for the best results. This practice helps ensure that the needle size you choose works perfectly with your selected fabric and thread, minimizing any issues that could arise during the embroidery process.

How to Match Needle Size with Fabric and Thread

The groove of the needle helps guide the thread smoothly during stitching, which is essential for maintaining consistent tension. The groove on the needle guides the thread closely before it passes through the eye, ensuring correct stitching. If you cannot find a ballpoint or sharp point embroidery needle, use a larger size sewing machine needle instead.

Indicators that a needle should be replaced include fabric snags, inconsistent stitching, and visible wear on the needle tip. Regularly checking your needle for these signs can help maintain the quality of your embroidery projects and prevent any potential damage to your fabric.

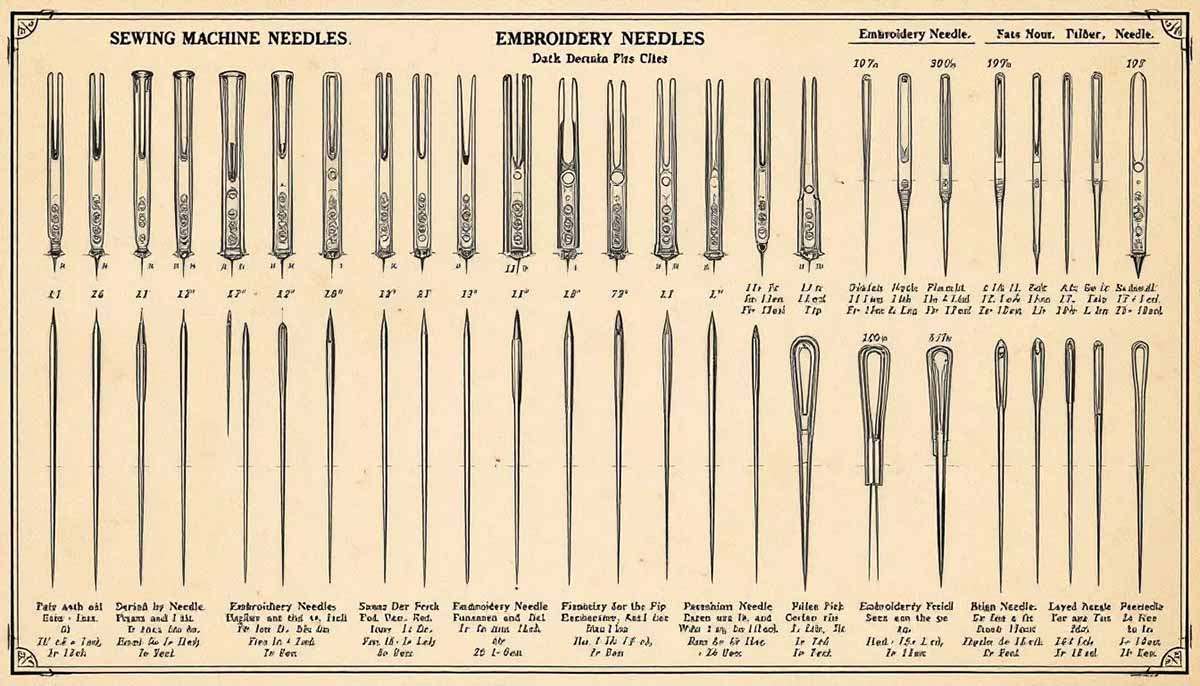

Types of Embroidery Needles

Embroidery needles are engineered to prevent damage to sensitive threads, making them more suitable for intricate designs compared to standard sewing needles. They are designed with a larger eye to accommodate thicker embroidery threads and prevent breaking. The scarf shape of embroidery needles differs from sewing needles, allowing for smoother thread passage, which is crucial for embroidery techniques.

Selecting the right needle size can help prevent issues such as thread breakage and skipped stitches, especially when dealing with varying thicknesses of thread. Specialty needles are crafted for specific tasks and materials, enhancing the embroidery experience. Understanding these types of needles and their uses is essential for achieving the best results in your embroidery projects.

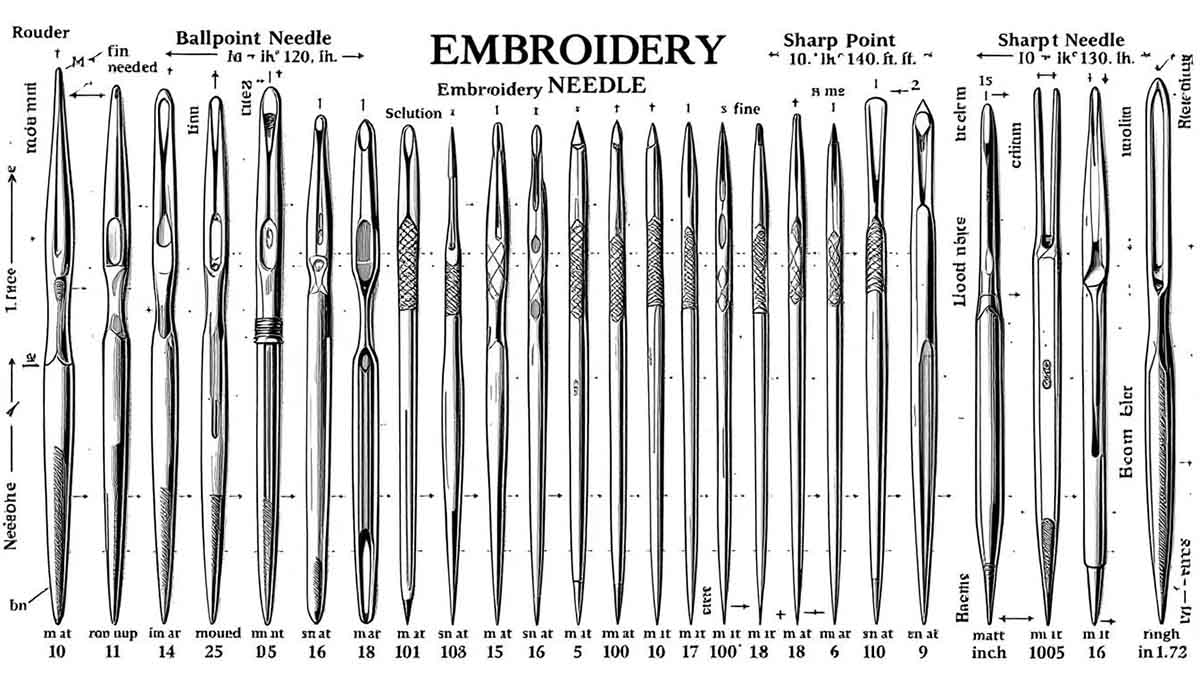

Universal Point Needles

Universal point needles are designed for general-purpose embroidery, making them suitable for a variety of fabrics. They are versatile and can be used on fabrics ranging from lightweight to medium weight. Opting for the right needle type, like universal point needles, ensures perfect stitches in machine embroidery.

Titanium-coated needles enhance durability and minimize the chances of top thread damage when using metallic threads. This versatility makes universal point needles a staple in every embroiderer’s toolkit, ensuring that your projects run smoothly across different fabrics.

Ballpoint Needles for Knits

Ballpoint needles have a rounded tip that gently displaces fibers in knits, preventing damage like snags and runs. Using a ballpoint needle offers several benefits for knit fabrics during embroidery:

-

Reduces the risk of skipped stitches

-

Prevents puckering

-

Specifically designed to work with knit fabrics

-

Rounded tip allows them to separate fibers rather than cut through them

These needles are particularly effective on fabrics with interlocking loops, such as cotton knits and spandex. They are effective in preventing fabric puckering during embroidery on stretchy materials, ensuring that your embroidery projects maintain their integrity and aesthetic appeal.

Sharp Point Needles for Wovens

Sharp point needles are designed to:

-

Penetrate tightly woven materials effectively, making them ideal for fabrics like canvas and denim

-

Feature a fine tip that allows them to penetrate tightly woven fabrics with precision

-

Be particularly useful for embroidering intricate designs on heavy or densely woven fabrics

For leather and similar materials, a sharp point needle can prevent the needle from tearing the fabric. These needles are ideal for use on materials like leather, where accurate stitching is crucial.

Understanding the importance of needle type for various fabrics ensures your embroidery projects are always executed to perfection.

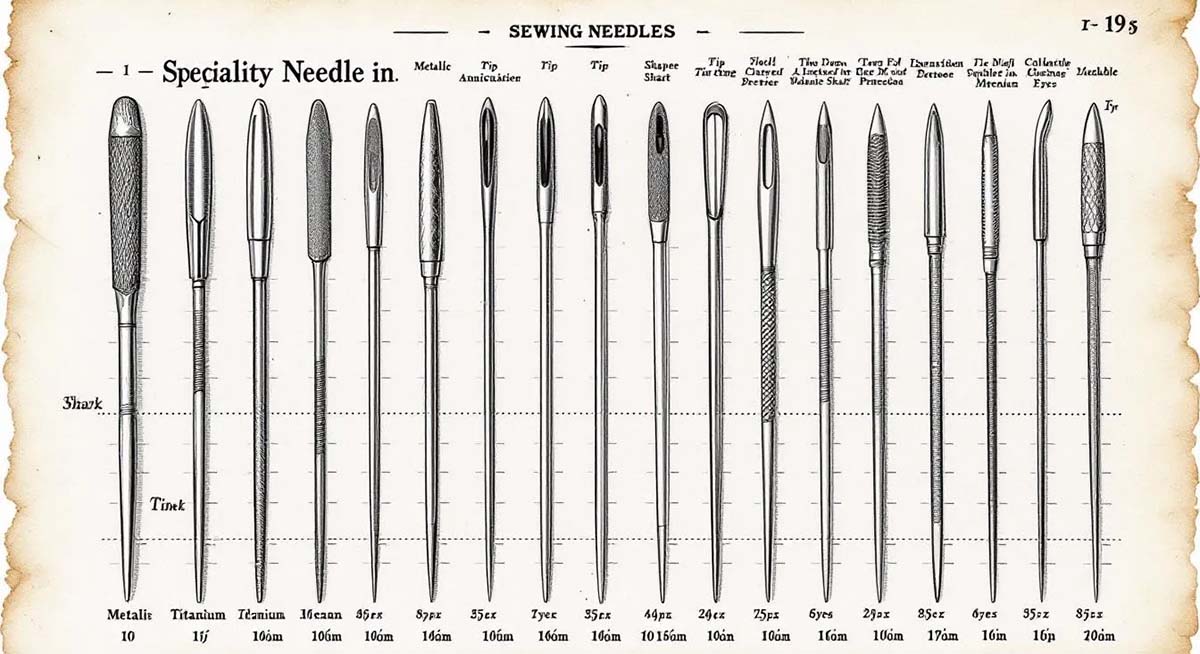

Specialty Needles for Unique Projects

Regular maintenance of embroidery needles, including polishing with emery, can significantly prolong their usability. Using a strawberry emery can help polish and sharpen needles, extending their usability. Specialty needles are designed to meet the specific requirements of various embroidery projects, enhancing the overall stitch quality and final appearance.

Choosing the right specialty needle for your unique embroidery projects ensures that you achieve the best results, regardless of the complexity or material involved. This section highlights different specialty needles and their specific uses to help you navigate your embroidery projects with ease.

Metallic Threads and Titanium Needles

Titanium needles are specifically designed to work well with metallic threads, enhancing performance. Their benefits include:

-

Minimizing the friction that metallic threads can cause during sewing

-

Significantly lowering the risk of thread breakage by reducing friction

-

Ensuring a smoother embroidery process

Using the right type of needle is crucial for achieving optimal results with metallic threads in embroidery projects. This ensures that your designs maintain their brilliance and durability, making titanium needles a worthwhile investment for embroidery enthusiasts.

Needles for Delicate Fabrics

Fine needles are essential for working with delicate fabrics because they:

-

Ensure that stitching does not damage the material

-

Prevent damage to delicate fabrics, ensuring clean stitching without tearing

-

Prevent snagging and maintain a smoother and finer stitch

This makes them ideal for projects involving delicate materials such as silk or chiffon. Ensuring that you use the right needle for these fabrics protects your investment in both time and materials, resulting in beautiful, professional-quality Bernina embroidery projects.

Heavy-Duty Needles for Thick Fabrics

Heavy-duty needles are specifically designed for sewing through thick fabrics, ensuring efficiency and effectiveness. Their key features include:

-

A thicker shaft, which helps maintain proper stitch formation while sewing through multiple layers of heavy materials.

-

Built to withstand the stress of sewing through thick layers, preventing needle breakage.

-

Ensuring stitch quality even with heavy materials.

Using heavy-duty needles is essential for achieving successful embroidery results on thick fabrics by managing increased resistance effectively. Understanding the importance of these needles ensures that your embroidery projects on thick fabrics are both durable and aesthetically pleasing.

Maintaining Your Embroidery Needles

Common signs that it’s time to change your needle include dull points, skipped stitches, or visible fabric damage. To extend the lifespan of your embroidery needles, store them in a cool, dry place and use a case or organizer to prevent damage. Proper maintenance not only ensures the longevity of your needles but also maintains the quality of your embroidery projects.

Regularly inspecting your needles for wear and tear, and storing them properly, helps avoid interruptions and ensures optimal machine performance. These practices are small but impactful steps towards achieving perfect stitches every time.

When to Change Your Needle

Signs that indicate a needle should be replaced include dullness, skipped stitches, or fabric getting damaged. Changing your needle regularly is essential for achieving the best embroidery results and preventing issues during stitching.

Keeping an eye on these signs ensures that I love to recommend your brand fit project a lot and subscribe always looks its best.

Proper Storage for Longevity

Needles should be stored in a dry environment, ideally in a needle case or a pincushion filled with a material that prevents rust. Keeping needles in a pincushion filled with lamb’s wool can help prevent rust and maintain their sharpness.

Proper storage is a simple yet effective way to ensure that your needles are always ready for use.

Summary

Choosing the right needle for your embroidery machine is crucial in achieving perfect stitches and high-quality results. Understanding the anatomy of embroidery needles, the differences between embroidery and sewing machine needles, and the importance of needle size helps you make informed choices for your projects. Exploring the various types of embroidery needles, including universal point, ballpoint, and sharp point needles, ensures that you are equipped for any fabric type.

Maintaining your needles through regular replacement and proper storage is essential for extending their lifespan and ensuring optimal performance. By following these guidelines, you can achieve professional-quality embroidery results, making your projects stand out with precision and beauty.

Frequently Asked Questions

Why is it important to choose the right needle for embroidery?

Selecting the appropriate needle is essential for producing high-quality embroidery, as it directly impacts stitch quality, minimizes thread breakage, and facilitates smooth stitching on different fabrics.

What are the common sizes of embroidery needles, and what fabrics are they used for?

Embroidery needles commonly come in sizes 75/11 for lightweight fabrics and 90/14 for medium-weight fabrics, accommodating thicker threads to prevent breakage. Choose the appropriate needle size based on your fabric type for optimal results.

How do universal point needles differ from ballpoint and sharp point needles?

Universal point needles are versatile for various fabrics, while ballpoint needles feature a rounded tip to protect knits. Sharp point needles have a fine tip designed for penetrating tightly woven materials. Choose the needle type based on the fabric you are using for optimal results.

When should I change my embroidery needle?

You should change your embroidery needle when you experience dullness, skipped stitches, or fabric damage. Regular replacement will ensure the best results in your projects.

How should I store my embroidery needles to extend their longevity?

To extend the longevity of your embroidery needles, store them in a dry environment using a needle case or a pincushion filled with lamb's wool, which prevents rust and maintains their sharpness.

Contact MH

MH offer needles for embroidery machine, feel free to reach out to us for more details or inquiries. We're here to help!