The Ultimate Guide to the Needle for Sewing Machine for Garment Manufacturers

Sewing machine needles are the unsung heroes of garment manufacturing. While they may seem like a small, insignificant component, the truth is that they play a pivotal role in the efficiency and quality of every garment produced. Selecting the right needle for sewing machine operations can mean the difference between flawless seams and frequent production headaches.

For garment manufacturers, understanding sewing machine needles is not optional. Proper needle selection directly impacts fabric integrity, seam durability, and overall garment quality. This blog will serve as a comprehensive guide for selecting and maintaining the best needle for your sewing machine needs, ensuring optimal results for every project.

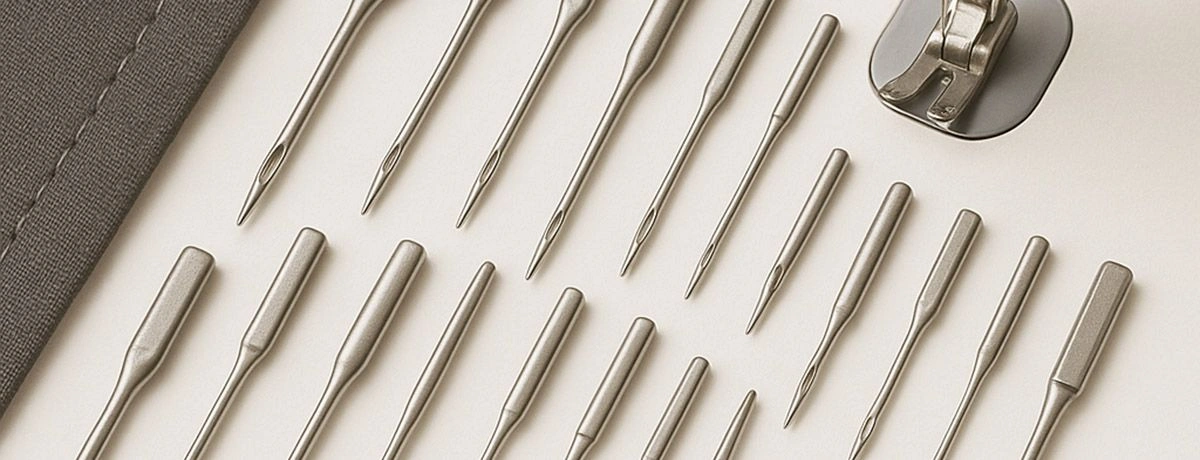

Understanding Sewing Machine Needle Types and Sizes

Before we discuss specific sewing needle types or how to choose them, it’s important to understand the basic anatomy of a sewing machine needle and how its size and type affect performance. Sewing machine needle sizes are determined using different measuring systems, such as metric (millimeters) and US standard (numbers), and understanding these systems is crucial for selecting the right needle.

Key Parts of a Sewing Machine Needle

Here’s a quick breakdown of the key components of any sewing machine needle:

-

Shank: The upper part of the needle that fits into the sewing machine. It is flat on one side for correct alignment.

-

Shaft: The narrower part of the needle that tapers down from the shank. It moves through the fabric during stitching.

-

Eye: A small hole near the tip where the thread is passed through.

-

Groove: The long indentation running along the shaft of the needle. The groove helps guide the thread smoothly through the fabric and is especially important for techniques like topstitching, as it accommodates multiple threads for bold, decorative stitches.

-

Point: The sharp tip of the needle that penetrates the fabric.

Each part is designed to influence how the needle interacts with the fabric, thread, and machine.

Needle Sizes

Needle sizes are usually denoted by two numbers, such as 80/12. The first number (80) is European sizing, while the second (12) is American sizing. Both refer to the diameter of the needle’s shaft. Larger numbers indicate thicker needles designed for heavy fabrics, while a smaller needle size is ideal for lightweight fabrics like chiffon or silk, helping to achieve smooth stitching and prevent fabric damage.

For example:

-

Smaller sizes (60/8 or 70/10): A smaller needle size is suited for thin, lightweight fabrics such as chiffon or silk, ensuring smooth stitching and minimizing the risk of fabric damage.

-

Medium sizes (80/12 or 90/14) work best for general sewing and medium-weight fabrics like cotton.

-

Larger sizes (100/16 and up) are ideal for heavy fabrics like denim or canvas.

Different Types of Sewing Machine Needles and Their Uses

Garment manufacturers often work with a variety of fabrics and threads, so understanding specific sewing needle types and how to use them can help improve efficiency and product quality. Using different needles for various fabrics and machines ensures optimal stitching results and reduces production issues. Below are some of the most common needle types:

1. Universal Needles

-

Use case: All-purpose sewing; works with both wovens and knits, making universal needles a versatile choice for a wide range of fabric types.

-

Ideal for: Beginners or general garment construction.

-

Example: Creating basic cotton shirts or simple dresses.

2. Ballpoint Needles

-

Use case: Knit fabrics; slides between loops instead of piercing them.

-

Ideal for: Prevents skipped stitches or runs in knit materials like jersey or spandex. A jersey needle is a specific type of ballpoint needle designed for sewing jersey and other stretch knit fabrics.

3. Jeans/Denim Needles

-

Use case: For heavy, tightly woven, thick, and heavier fabrics. These needles are designed to sew through thick and heavier fabrics without breaking.

-

Ideal for: Especially suited for thick fabrics like denim, canvas, and other heavyweight textiles requiring durable stitches.

-

Tip: Use strong polyester thread to match the heavy-duty sewing power of these needles.

4. Stretch Needles

-

Use case: Elastic fabrics; prevents skipped stitches caused by fabric movement.

-

Ideal for: Swimwear, activewear, or lingerie.

5. Leather Needles

-

Use case: For leather, vinyl, and other non-woven synthetic materials.

-

Ideal for: Creating clean holes in leather and similar materials, allowing for strong, durable seams without tearing the fabric.

-

Note: Not suitable for woven or knitted fabrics.

6. Microtex/Sharp Needles

-

Use case: Microtex needles, also known as microtex needle or fine needle, are designed for precision sewing on delicate or finicky fabrics.

-

Ideal for: Silk, lightweight cotton, and fine embroidery, where the sharp tip of microtex needles provides smooth, precise stitches—unlike the rounded tip of ballpoint needles.

By choosing the right needle type for your materials, manufacturers can significantly reduce errors like skipped stitches, fabric damage, or thread breakage.

How to Choose the Right Sewing Machine Needle for Your Project

Selecting the correct needle for sewing machine operations involves several factors, including fabric type, thread thickness, and the intended function of the garment. Choosing the right needle is essential for any sewing project, whether you are working in a manufacturing setting or focusing on home sewing tasks.

Follow these steps for smarter needle choices so you can sew with confidence and achieve the best results for your next sewing project:

1. Identify Your Fabric Type

Start by assessing the fabric you’re working with. For instance:

-

Use a ballpoint needle for stretchy knit fabrics.

-

Choose a sharp needle for tightly woven materials like silk, microfiber, or wool.

2. Match the Needle Size to the Fabric Weight

Lightweight fabrics such as chiffon or silk require smaller needle sizes (60/8 - 70/10) to ensure smooth stitching and prevent fabric damage, whereas thicker fabrics like jeans or canvas need larger needles (100/16 or above).

3. Consider the Thread

Ensure your needle size matches the thickness of the thread you’re using. For thicker threads, opt for a larger needle eye to prevent breakage.

4. Think About the Purpose

If the garment will undergo high wear and tear (e.g., activewear or workwear), prioritize durable needle types like stretch or denim needles. For quilting projects, use specialized quilting needles designed to handle multiple layers and thick fabrics.

5. Test Before Starting

Always test the needle on a scrap piece of fabric to confirm optimal performance and to ensure it won't break during actual sewing, especially when working with thick or reinforced materials.

Tips for Maintaining Your Sewing Machine Needles

Proper maintenance not only extends the life of your sewing machine needle but also ensures consistent garment quality. Improper pushing or forcing fabric through the machine can cause needles to bend or break, so always use proper technique and avoid aggressive handling.

1. Replace Needles Regularly

A common mistake manufacturers make is reusing dull needles. A general rule of thumb is to replace the needle after every 8-10 hours of machine use.

2. Keep a Needle Organizer

Label needles by type and size to quickly find the right one for your next project.

3. Check for Damage

Bent or blunt needles can damage fabric or cause stitching issues. Inspect needles before use and discard any damaged ones.

4. Use High-Quality Needles

Invest in premium brands that guarantee durability and precision. Cheaper needles may fail under high-volume production.

5. Clean Your Machine

Dust and lint can accumulate around the needle area. Regular cleaning keeps the needles functioning properly and reduces wear.

Optimizing Garment Quality with Proper Needle Selection

Sewing machine needles may seem like minor components, but they are foundational to production efficiency and garment excellence in the world of wholesale and manufacturing. By understanding needle types, using appropriate sizes, and properly maintaining each tool, garment manufacturers can avoid costly errors and elevate their output quality. Selecting the right universal needle or ball point needle for the fabric type helps achieve smooth, even stitches and prevents fabric damage.

Want to simplify needle selection for your production line? Explore our comprehensive range of high-quality sewing machine needles, tailored for various materials and applications. Whether you’re producing fine silk blouses or heavy-duty denim, we have the tools you need for precision and performance.

Browse our selection of sewing needles to find what suits your business best. Contact us for expert advice or to place your order today!