What Are Oxford Fabrics and Why Are They Essential for Garment Applications?

If you’re sourcing fabric for bags, tents, or workwear, you’ve likely encountered Oxford on spec sheets and tender documents. This guide cuts through the basics and delivers the technical details procurement managers actually need—denier ranges, coating options, and material comparisons that translate directly to product performance.

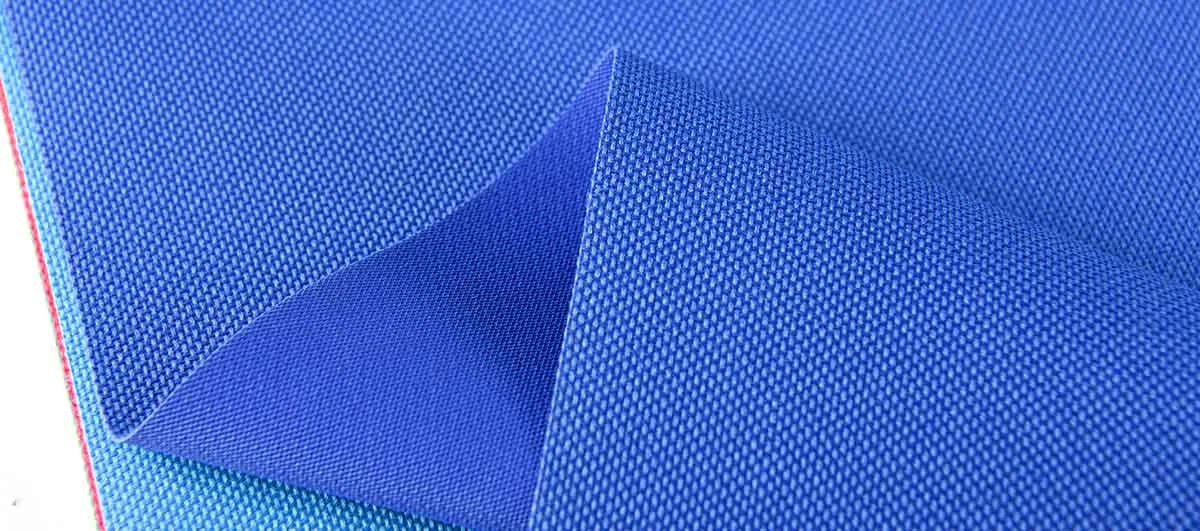

Oxford fabric is a type of woven textile known for its basket weave structure, which gives it a distinctive texture and excellent durability. Key features of Oxford fabric include its unique grid-like weave, use of durable materials such as polyester, nylon, or cotton, and its versatility across both industrial and apparel applications. These qualities set Oxford fabric apart from other woven textiles. While modern Oxford fabrics are often made from polyester or nylon for industrial and outdoor use, not the cotton oxford cloth historically used for dress shirts and oxford shirts. Oxford cloth is also used for other apparel items such as dresses and skirts, valued for its structure and durability. There are several types of Oxford fabric, including Plain Oxford, Pinpoint Oxford, and Royal Oxford, each varying in texture and application. Pinpoint Oxford is a refined version made with finer yarns, resulting in a softer, smoother, and more formal fabric suitable for dress shirts.

The basket weave structure of Oxford fabric is characterized by pairs of yarns woven together, creating a subtle checkerboard effect. The classic Oxford weave is identifiable by its evenly spaced grid-like pattern and dual warp yarns crossing weft yarns. This differs from twill, which features a diagonal weave pattern that gives twill fabrics their signature slanted lines, while Oxford’s basket weave creates a unique grid-like appearance. The basket weave structure improves tear strength and abrasion resistance compared with plain weave fabrics at equivalent weight. The tight weave of Oxford fabric contributes to its strength and durability, making it resistant to wear and tear.

What Is Oxford Fabric? (Quick Answer for B2B Buyers)

Oxford fabric is a durable textile defined by its basket weave structure, where multiple warp yarns interlace with weft threads to create a distinctive textured surface with superior tear resistance. In modern industrial applications, Oxford refers primarily to polyester or nylon woven in 2×1 or 2×2 basket patterns—not the cotton oxford cloth historically used for dress shirts and oxford shirts.

This versatile fabric has evolved far beyond its origins at Oxford University as a shirting material. The oxford cloth button down shirt (OCBD) is a classic, durable, and versatile wardrobe staple, valued for its comfort, neat appearance, and traditional use in both casual and workwear shirts. Today, it’s a workhorse textile for bags, tents, covers, and workwear applications where durability and consistent performance matter more than softness.

Denier ranges typically break down by application:

|

Denier Range |

Typical Applications |

|---|---|

|

150D–300D |

Light bags, linings, promotional items |

|

420D–600D |

Backpacks, school bags, everyday luggage |

|

900D–1200D |

Heavy-duty trolleys, tactical gear |

|

1680D |

Ballistic luggage, premium outdoor gear |

The basket weave structure improves tear strength and abrasion resistance compared with plain weave fabrics at equivalent weight. This happens because stress distributes across multiple binding points rather than concentrating on single yarn intersections.

At MH, we produce make-to-order Oxford fabrics with PU, PVC, PA, and ULY coatings. We do not run spot stock—our minimum order amount (MOA) is USD 3,000 per shipment, which allows us to customize specifications precisely to your requirements.

Key Technical Features of Oxford Fabric

Uncoated Oxford feels more flexible and maintains better breathability—suitable for garments, casual bags, and applications where rigidity isn’t required. Coated Oxford becomes stiffer and more structured, making it ideal for bags that need to hold their shape and covers that must resist water penetration. Oxford fabric is often treated to enhance its water resistant properties, making it suitable for outdoor applications.

The coating also affects how the fabric behaves during cutting and sewing. Coatings like PU or PVC can make Oxford fabric waterproof and UV-resistant for industrial and medical use. PVC-coated Oxford, for instance, may require adjusted needle specifications and slower stitching speeds to prevent puckering. Stretch testing is often used to verify the weave structure and recovery of Oxford fabrics, helping to assess overall quality.

The tight, robust weave of Oxford fabric contributes to its strength and durability. This weave makes Oxford exceptionally resistant to tearing and abrasion, and it often softens with age and washing.

Polyester vs. Nylon Oxford: How to Choose

We supply both polyester oxford and nylon Oxford at MH, and each material suits different performance requirements and budget constraints. Understanding these differences helps you specify the right fabric for your B2B projects. Some Oxford fabrics, especially those made with polyester blends, are valued for their wrinkle resistant properties, making them ideal for products that need to maintain a neat appearance.

Polyester Oxford

Polyester Oxford dominates the mid-market for good reason. It offers excellent color fastness, dimensional stability, and resistance to UV degradation—all critical for products that see regular sun exposure. The material is cost-effective, with production costs running 20-30% lower than equivalent nylon constructions.

Polyester resists wrinkles better than nylon (showing 20-30% better recovery in industry tests), which matters for products that ship folded or get compressed during transport and storage. It absorbs minimal moisture—around 0.4% compared to nylon’s 4-8%—so it dries faster and resists mildew growth.

Best applications: School bags, promotional backpacks, trolley cases, workwear jackets, and outdoor covers where cost-effectiveness matters.

Nylon Oxford

Nylon Oxford delivers higher tear strength and abrasion resistance at the same denier rating. The polyamide fibers provide natural elasticity and a softer hand feel. You’ll notice nylon feels slightly “waxy” to the touch and has stronger recovery when crumpled.

The trade-offs include higher material costs, greater UV sensitivity (requiring stabilizers or coatings), and increased moisture absorption that can affect drying times and long-term mildew resistance.

Best applications: Outdoor sports bags, tactical gear, high-end luggage, and tents where maximum durability justifies the premium.

Quick Visual Identification

When comparing samples, polyester Oxford appears more matte and feels “crisp” or papery. Nylon Oxford has a subtle glossy sheen and feels smoother, almost slippery. Crumple both fabrics and release—nylon bounces back faster and more completely.

Spec Comparison Example:

-

600D polyester Oxford with PU coating: Suitable for everyday backpacks, school bags, and entry-level luggage

-

420D nylon Oxford with PU coating: Recommended for outdoor gear, sports bags, and products requiring superior flex fatigue performance

Understanding Denier, Coatings, and Performance

Denier (D) combined with coating type largely determines how Oxford fabric performs in real-world use. Getting these specifications right is the difference between a product that lasts and one that fails prematurely.

Denier Explained

Denier measures yarn thickness based on the mass in grams of 9,000 meters of fiber. Higher denier means thicker, heavier yarns that produce stronger, more abrasion resistant fabric—but also add weight.

|

Denier |

Characteristics |

Typical Uses |

|---|---|---|

|

150D–210D |

Lightweight, flexible, economical |

Linings, light bags, garment details |

|

300D–420D |

Balanced weight and durability |

Shopping bags, everyday backpacks |

|

600D |

Industry standard mid-weight |

School bags, workwear, outdoor covers |

|

900D–1200D |

Heavy, structured, highly durable |

Premium luggage, tactical applications |

|

1680D |

Maximum strength, significant weight |

Ballistic bags, heavy-duty outdoor gear |

Higher-denier variants excel in standardized tests like ASTM D2261 for tear strength, but the weight penalty may not suit all applications.

PU Coating (Polyurethane)

PU coating creates a lightweight, soft layer that provides water resistance while maintaining fabric flexibility and drape. It’s breathable enough for workwear applications and common in 210D–600D fabrics for backpacks, school bags, and jackets.

Typical water column ratings range from 300mm to 3000mm depending on coating thickness. PU-coated Oxford remains the popular choice for products requiring some weather protection without excessive stiffness.

PVC Coating (Polyvinyl Chloride)

PVC delivers heavier, stiffer waterproof performance with excellent dimensional stability. The trade-off is reduced breathability and added weight—but for trolley cases, tool bags, rain covers, and economic tents, these trade-offs make sense.

PVC-coated Oxford handles abrasion well and cleans easily, making it suitable for industrial environments and products exposed to dirt and grime.

PA Coating (Polyamide)

PA coating—essentially a thin nylon back-coating—improves fabric stability and provides down-proofing properties. It’s commonly used for lighter fabrics and linings where you need enhanced performance without significant weight or stiffness increases.

ULY Coating (Ultra-Low Yellowing / Advanced PU)

ULY represents upgraded polyurethane technology with better hydrolysis resistance and anti-yellowing properties. This coating maintains appearance and performance over extended use, making it suitable for high-end bags and outdoor products with long service life expectations.

Custom Finishing at MH

We can tune coating thickness from approximately 300mm to 1500mm water column depending on your waterproof testing requirements. Surface finishing options include matte or glossy, plain or embossed textures, matched to your product’s target market and functional specifications.

Application-Specific Oxford Fabrics: Bags, Tents, and Workwear

With over 20 years of export experience, MH supplies Oxford fabrics to global brands across luggage, outdoor gear, and industrial workwear sectors. Here’s how specifications typically break down by application.

Bags & Luggage

The bags market demands different Oxford constructions depending on price point and intended use:

-

300D polyester PU: Shopping bags, promotional giveaways, lightweight everyday use

-

600D polyester PVC: School bags, standard backpacks, entry-level luggage

-

1680D nylon PU: Premium trolleys, business bags, luggage requiring maximum durability

Customization options include color matching (we can hit Pantone references), print application, and surface embossing for brand differentiation. The sturdy construction of higher-denier Oxford makes it commonly used for reinforcement panels on bag bottoms and corners.

Tents & Outdoor Covers

Outdoor applications require weather resistance as a baseline. We typically recommend:

-

210D/300D polyester Oxford with PU or PA coating: Entry-level camping tents, car covers

-

420D polyester Oxford with enhanced PU: Mid-range outdoor gear, garden furniture covers

-

Flame retardant and UV-resistant treatments: Available for commercial and industrial tent applications

Water resistance levels can be specified based on your target market’s climate conditions and expected product lifespan.

Workwear & Uniforms

Industrial workwear benefits from mid-weight polyester Oxford with breathable PU or PA backing. These fabrics work well for:

-

Jacket shells and reinforcement panels

-

Safety vest substrates

-

Knee and elbow reinforcement on coveralls

-

School uniforms requiring durability and easy care

Oxford integrates well with reflective tapes and functional trims—all of which MH supplies, allowing you to consolidate sourcing and simplify your supply chain.

Custom Specification Development

Our technical team works directly with your product development staff to match fabric specifications to tech pack requirements. Whether you’re targeting European outdoor retailers, North American school uniform contracts, or Latin American promotional goods manufacturers, we adjust denier, GSM, coating, color, and finishing accordingly.

Quality, Testing, and Certifications at MH

B2B buyers need consistent, testable performance—not marketing claims. We design Oxford fabrics around lab-tested data that you can verify and reference in your own specifications.

Internal Testing Protocols

Every Oxford production run undergoes testing for:

-

Tensile strength: Breaking force in warp and weft directions

-

Tear strength: Elmendorf or tongue tear methods per ASTM standards

-

Abrasion resistance: Martindale or rotary drum testing with defined cycle counts

-

Hydrostatic pressure: Water column testing for coated fabrics

-

Color fastness: To washing, rubbing, and light exposure

These tests establish baseline performance data that travels with your order documentation.

Quality Systems and Certifications

MH maintains ISO 9001 quality management certification. Selected Oxford fabric lines carry OEKO-TEX STANDARD 100 certification, and we maintain REACH-compliant chemical management practices for European market requirements.

Traceable Production

From yarn selection through weaving, dyeing, coating, and final inspection, our production maintains batch control suitable for large, repeated orders. This traceability matters when you’re building long-term supplier relationships and need consistency across multiple shipments.

Third-Party Testing Support

We routinely support buyer-specified third-party testing through SGS, Bureau Veritas, Intertek, and other accredited laboratories. If your tender documents specify particular test methods or performance thresholds, our technical team can advise on fabric specifications likely to meet those requirements before you commit to bulk production.

MH’s Make-to-Order Service

MH operates as a make-to-order factory for Oxford fabrics—we do not maintain spot stock. Our minimum order amount (MOA) is USD 3,000 per shipment, with flexibility to combine multiple colors and deniers within a single production run.

Development Process

The typical sourcing workflow follows these steps:

-

Specification submission: You send target specs, a physical sample, or a reference product

-

Technical proposal: We propose matching or optimized specifications based on your requirements

-

Lab dips and hand samples: Color matching and hand-feel approval before bulk commitment

-

Confirmation and production: Bulk weaving, dyeing, coating, and quality inspection

-

Shipment: Export packing suitable for sea or air freight

Lead Times

Realistic lead times run 20–35 days after sample approval, depending on order volume, coating complexity, and finishing requirements. Rush production is possible for some constructions with prior arrangement.

Oxford fabric remains a versatile textile foundation for durable goods across industries. Whether you’re specifying material for promotional backpacks or premium outdoor gear, understanding the technical variables—weave structure, denier, coating type, and base material—helps you source smarter and build better products.

Ready to discuss your next Oxford fabric project? Contact MH for specifications, samples, and production timelines tailored to your requirements.

Conclusion

In conclusion, oxford fabric remains a timeless and versatile textile, celebrated for its unique blend of durability, breathability, and style. From its origins as oxford cloth associated with Oxford University to its modern roles in outdoor gear, workwear, and everyday clothing, oxford fabric has consistently proven itself as a reliable and popular choice. Whether you’re selecting plain oxford for casual shirts, royal oxford for refined dress shirts, or polyester oxford for rugged bags and outdoor applications, there’s a specific type of oxford fabric to meet every requirement.

Its enduring appeal lies in its ability to combine strength and comfort, making it suitable for a wide range of products—from clothing and bags to workwear and outdoor gear. By understanding the benefits, care, and maintenance of oxford fabric, B2B buyers and designers can confidently choose this material for projects that demand quality, versatility, and long-lasting performance. As a staple in the textile industry, oxford fabric continues to set the standard for durability and style, living up to its prestigious heritage and remaining a top choice for manufacturers and brands worldwide.