How to Choose PVC Coated Cloth for Tents, Tarps, and Industrial?

In today’s industrial landscape, the demand for versatile, durable materials that can withstand harsh environmental conditions while providing reliable protection continues to grow. PVC coated cloth has emerged as a critical solution for manufacturers, importers, and industrial buyers seeking cost-effective, high-performance fabrics. As a leading global B2B textile manufacturer, MH understands the complexities of sourcing the right coated fabrics for your specific applications.

This comprehensive guide explores everything you need to know about PVC coated cloth, from technical specifications and manufacturing processes to bulk sourcing strategies and quality considerations. Whether you’re a facility manager choosing covers for industrial equipment, an importer evaluating fabric suppliers, or a manufacturer designing products that require waterproof materials, this guide will provide the insights necessary to make informed procurement decisions.

What is PVC Coated Cloth

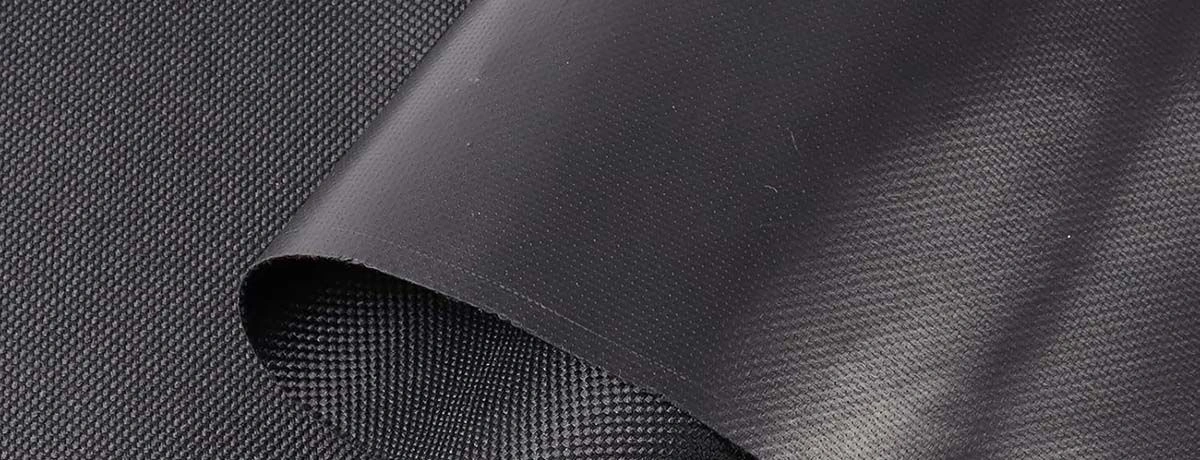

PVC coated cloth represents a sophisticated composite material where polyvinyl chloride resin is applied to textile substrates through advanced coating processes. This marriage of polymer chemistry and textile engineering creates a versatile fabric that combines the mechanical strength of woven base materials with the protective properties of PVC compounds.

The fundamental structure consists of a base fabric—typically polyester, cotton, or nylon—that serves as the structural foundation, while the PVC coating layer provides the functional benefits. This dual-component design enables manufacturers to engineer products that meet specific performance requirements while maintaining cost efficiency at scale.

Key characteristics that make this material ideal for industrial applications include exceptional waterproof properties, robust chemical resistance, and remarkable flexibility across temperature ranges. The vinyl layer creates an impermeable barrier that prevents moisture penetration while maintaining the structural integrity needed for demanding applications. Unlike laminated alternatives, true coated fabrics achieve superior fusion between the coating and substrate, resulting in enhanced durability and tear resistance.

The versatility of this material has led to its widespread adoption across industrial, architectural, and protective equipment sectors. From heavy-duty tarpaulins protecting valuable cargo to sophisticated architectural membranes covering large-span structures, PVC coated cloth delivers reliable performance where other materials might fail.

Understanding the science behind this material helps buyers make informed decisions about specifications, quality requirements, and sourcing strategies. The coating process creates a chemical bond with the base fabric, ensuring long-term adhesion and preventing delamination issues common with inferior products.

Types

The diversity of PVC coated cloth types reflects the wide range of performance requirements across industrial applications. Understanding these categories helps buyers select optimal materials while avoiding over-specification that increases costs unnecessarily.

Heavy-duty PVC coated polyester, ranging from 610 to 1500GSM, serves as the backbone for tarpaulins and truck covers where exceptional tear strength and puncture resistance are paramount. These materials typically feature high-tenacity polyester scrims with substantial PVC add-on weights to create robust barriers against mechanical damage and environmental stress.

Architectural grade materials, spanning 450 to 900GSM, incorporate specialized topcoats designed for tensile structures and permanent installations. These products balance structural performance with aesthetic requirements, often featuring enhanced UV packages and soil-resistant surface treatments that maintain appearance over extended exposure periods.

Lightweight coated fabrics in the 200 to 400GSM range target applications like bags and temporary covers where weight reduction and packability take priority over maximum durability. These materials demonstrate that effective protection doesn’t always require maximum coating thickness.

Mesh constructions with 30% to 70% openness factors provide controlled ventilation for shade and screening applications. The open area percentage directly impacts wind load characteristics and light transmission, allowing designers to specify exactly the right balance for each application.

Key Characteristics and Properties

Understanding the performance envelope of PVC coated cloth enables buyers to match material specifications precisely to application requirements. Physical properties represent the foundation for performance prediction and quality verification.

Tensile strength specifications ranging from 280 to 3500 N/5cm reflect the dramatic impact of base fabric construction and coating weight on mechanical performance. Heavy-duty constructions achieve the highest values through combination of high-tenacity yarns and substantial coating add-on, while lighter constructions optimize flexibility and handling characteristics.

Tear resistance, measured using standardized tongue method testing, typically ranges from 80 to 450 N depending on fabric construction and coating penetration. This property proves critical for applications where fabric edges experience high stress concentrations or where small punctures might propagate into large failures.

Temperature performance spans from -30°C to +70°C for standard formulations, though specialized compounds can extend this range significantly. Low-temperature flexibility maintains bend properties crucial for winter installations, while heat resistance prevents softening and creep under summer sun exposure.

Water resistance measurements typically exceed 2000mm water column pressure ratings, far surpassing requirements for most weather protection applications. This exceptional hydrostatic head performance ensures reliable moisture barriers even under extreme conditions.

Chemical and Environmental Resistance

UV resistance testing demonstrates material longevity under solar exposure through accelerated testing protocols spanning 500 to 2000 hours. High-quality formulations maintain both physical properties and color stability throughout these demanding test cycles, predicting service lives measured in decades rather than years.

Chemical compatibility encompasses resistance to acids, alkalis, oils, and common solvents encountered across industrial environments. Comprehensive compatibility charts help buyers verify material selection for specific chemical exposure scenarios, preventing premature failure due to chemical attack.

Mildew and bacterial resistance proves essential for applications in humid environments where biological growth could compromise appearance and performance. Specialized biocide packages provide long-term protection without affecting other material properties or environmental compliance.

Low temperature flexibility characteristics determine suitability for cold climate installations where materials must maintain bend properties to -20°C or below. Standard formulations may become brittle at extreme temperatures, necessitating cold-resistant plasticizer systems for demanding applications.

Industrial Applications and Use Cases

The versatility of PVC coated cloth becomes evident when examining the breadth of industrial applications where these materials provide critical performance advantages. Each sector presents unique requirements that drive specific material optimizations.

Transportation applications dominate volume consumption, with truck tarpaulins, trailer curtains, and container covers representing massive global markets. These applications demand materials that withstand constant flexing, road vibration, and weather exposure while maintaining structural integrity over hundreds of thousands of miles. High-frequency welding capability enables rapid fabrication of complex shapes with permanent seam strength.

Architectural applications showcase the aesthetic potential of technical fabrics through tensile structures, awnings, canopies, and membrane roofing systems. These installations require materials that combine structural performance with visual appeal, often remaining in service for decades. Soil-resistant topcoats and fade-resistant colors maintain appearance throughout extended exposure cycles.

Agricultural sector applications include greenhouse covers, grain storage facilities, and livestock curtains where the material must resist agricultural chemicals while providing reliable environmental control. UV-stabilized formulations prevent degradation from intense solar exposure typical of farm environments.

Marine applications encompass boat covers, dock bumpers, and inflatable structures where saltwater resistance and flexibility under constant motion prove critical. These demanding environments require materials that resist corrosion, mildew, and UV damage while maintaining waterproof integrity.

Specialized Industrial Applications

Oil and gas industry applications include containment barriers, temporary shelters, and equipment covers that must resist petroleum products and provide flame-resistant protection. These critical applications often require materials meeting stringent fire codes and chemical resistance standards specific to hydrocarbon environments.

Construction industry utilization spans debris netting, scaffolding wraps, and weather protection systems that enable year-round building activities. High-visibility colors and flame-resistant properties enhance worker safety while providing reliable environmental barriers.

Military applications demand materials for field shelters, equipment covers, and modular structures that can deploy rapidly while providing reliable protection in extreme environments. These specialized products often incorporate camouflage patterns and enhanced tear propagation resistance for field durability.

Mining industry requirements include dust control barriers, equipment protection, and conveyor covers where materials must resist abrasive particles and harsh chemicals while maintaining visibility and access. Heavy-duty constructions provide extended service life despite aggressive operating conditions.

Performance Factors for Bulk Procurement

Successful bulk procurement of PVC coated cloth requires comprehensive understanding of performance factors that impact both initial quality and long-term service life. These metrics enable objective comparison between suppliers and materials.

Coating adhesion testing represents a fundamental quality indicator, with minimum 4 N/cm peel strength requirements ensuring long-term bond integrity. This test simulates the stresses that might cause coating separation during service, particularly important for applications involving repeated flexing or extreme temperature cycling.

Seam strength comparisons between RF welding and sewn seam performance reveal significant differences in ultimate strength and weather resistance. RF welded seams typically achieve 80-90% of base material strength while providing hermetic seals, whereas sewn seams may require additional sealing treatments for waterproof applications.

Dimensional stability testing verifies maximum 2% shrinkage under standard conditioning, preventing installation problems and maintaining proper fit over time. Materials that exceed these tolerances can cause costly field adjustments or premature failure due to overstress conditions.

Color fastness requirements typically specify Grade 4-5 ratings against UV exposure and washing cycles to ensure acceptable appearance throughout the service life. Poor color retention can necessitate premature replacement despite adequate physical performance, increasing lifecycle costs significantly.

Bulk Sourcing Considerations for Manufacturers

Effective bulk sourcing strategies for PVC coated cloth must balance quality requirements, cost optimization, and supply chain reliability. Industrial buyers face unique challenges when procuring these specialized materials at scale.

Minimum order quantities typically range from 3,000 to 10,000 linear meters per color, reflecting the economics of coating line setup and color changeover costs. Planning procurement around these minimums can achieve significant cost savings while ensuring adequate inventory levels for production requirements.

Lead times spanning 15-30 days for standard colors and 25-45 days for custom specifications require careful production planning and inventory management. Seasonal demand patterns and raw material availability can extend these timeframes, making accurate forecasting essential for maintaining production schedules.

Custom coating weights and widths become available for OEM applications when order volumes justify the additional setup costs. These customizations can optimize material properties for specific applications while potentially reducing fabrication waste and improving finished product performance.

Packaging options include various core tube sizes, palletized rolls, and protective wrapping configurations designed to protect materials during shipping and storage. Proper packaging prevents damage that could result in costly claims and production delays.

Partner with MH for Your PVC Coated Cloth Requirements

MH brings decades of experience as a global B2B textile manufacturer to every client relationship, combining technical expertise with manufacturing capabilities that consistently deliver quality results. Our comprehensive understanding of coated fabric applications enables us to provide solutions that go beyond simple material supply.

Our technical sales team offers specialized expertise in custom PVC coated cloth specifications, working closely with your engineers to develop materials that precisely match your performance requirements. This collaborative approach ensures optimal results while avoiding over-specification that unnecessarily increases costs.

Bulk pricing advantages become available for quantities exceeding 10,000 linear meters, reflecting our commitment to supporting large-scale industrial operations with competitive economics. Volume commitments enable us to optimize production efficiency while passing cost benefits to our valued customers.

OEM and ODM solutions represent a core strength at MH, where we develop specialized industrial applications through close collaboration with equipment manufacturers and system integrators. These partnerships often result in innovative solutions that create competitive advantages for our customers.

Facility tours and quality audits provide transparency into our manufacturing processes and quality systems, supporting supply chain qualification requirements and building confidence in our capabilities. We welcome the opportunity to demonstrate our commitment to excellence through direct observation of our operations.

Ready to learn more about how MH can support your PVC coated cloth requirements? Contact our technical sales team today to discuss your specific applications, explore custom specifications, and discover the advantages of partnering with a manufacturer committed to your success. Whether you need standard materials for immediate delivery or custom solutions for specialized applications, MH is ready to provide the expertise and service that makes the difference.

Choose MH as your trusted partner for bulk PVC coated cloth sourcing, where technical excellence meets commercial reliability. Let us show you why leading manufacturers worldwide trust MH for their most critical material requirements.