Sublimation Fabric: The Perfect Material for High-Quality Prints

Sublimation printing has become one of the most popular techniques for transferring vibrant, long-lasting designs onto fabric. Whether you're manufacturing sportswear, t-shirts, or soccer jerseys, sublimation fabrics offer unparalleled print quality and durability. In this blog, we’ll explore what sublimation fabric is, which fabrics are best for sublimation, and how MH company can help meet your needs with its range of high-performance sublimated fabrics.

What Is Sublimation Fabric?

Sublimation fabric refers to a type of textile specially designed to accept sublimation ink during the printing process. Sublimation is a dye-based method that involves turning solid dye particles into gas under heat, which then embeds into the fibers of the fabric, creating a seamless and permanent bond. This process is technically known as dye sublimation, where the dye transitions directly from solid to gas and fuses with the fabric at a molecular level.

Unlike traditional printing methods, which sit on top of the fabric, sublimation printing allows designs to become part of the fabric itself. Dye sublimation printing is especially effective for embedding vibrant, full-color designs into polyester-based fabrics through heat and pressure. This results in:

-

Vivid colors: Sublimation produces sharp, high-quality prints that are rich in color and detail.

-

Durability: Because the ink is infused into the fabric, the prints do not fade, peel, or crack over time.

-

Softness: The printing process does not add extra layers to the fabric, so the fabric remains soft and flexible.

-

Benefits: Sublimation printing offers superior image longevity, vibrant colors, detailed designs, and eco-friendly processes, making it a highly beneficial printing method.

The preferred material for sublimation is synthetic fiber, such as polyester, which provides a soft, shiny touch and optimal ink absorption. The result is a fabric that can withstand intense physical activities, frequent washing, and the wear and tear of everyday life—making it the go-to choice for high-performance sportswear and athletic apparel. Resistance to wrinkles is another benefit, helping maintain a smooth, professional finish after printing.

While polyester and other synthetic fibers are ideal for sublimation, natural fibers like silk are generally not suitable, as sublimation inks do not adhere well to them and produce inferior results.

Understanding the Sublimation Process

The sublimation process is a unique printing method that transforms solid dye directly into a gaseous state, bypassing the liquid phase entirely. This transformation occurs when high heat and pressure are applied, causing the sublimation inks to vaporize and penetrate deep into the fabric fibers. As the dye cools, it solidifies within the fibers, resulting in a print that is both vibrant and exceptionally durable.

This process is especially effective on synthetic fabrics like polyester, which have a molecular structure that readily absorbs the gaseous dye. The result is a seamless integration of color and fabric, producing prints that resist fading, peeling, and cracking—even after repeated washing and heavy use. By embedding the dye within the fibers rather than simply coating the surface, the sublimation process ensures that the printed image remains bright and intact for the life of the garment.

Understanding how the sublimation process works is key to achieving the best results. The combination of high heat, pressure, and the right fabric allows for the creation of stunning, long-lasting prints that stand out in both quality and durability.

What Fabric Is Best for Sublimation?

Not all fabrics are suitable for sublimation printing. The key factor in choosing the right material is the fiber composition. Sublimation printing works best on synthetic fibers, particularly those made from polyester. A blend of polyester with other fibers can further enhance ink absorption, print quality, and durability. Here are the best fabrics for sublimation:

1. Polyester Fabric

Polyester is the most popular fabric for sublimation printing due to its ability to bond with the sublimation dye. When the heat press is applied, the ink is absorbed into the polyester fibers, ensuring bright, long-lasting colors. It is highly durable, wrinkle-resistant, and moisture-wicking, which makes it perfect for activewear and sports apparel.

Advantages of using polyester for sublimation:

-

High color saturation and sharpness.

-

Soft to the touch and flexible.

-

Retains colors even after multiple washes.

2. Polyester Blends

Polyester blends, such as polyester-spandex, are another excellent choice for sublimation printing. The spandex component adds stretch and flexibility, which is ideal for form-fitting garments like athletic wear, t-shirts, and jerseys.

These fabrics combine the breathability and color retention of polyester with the comfort and stretchability of spandex, making them perfect for active wear that needs to move with the body.

3. Sublimation Coated Fabrics

Some fabrics, such as cotton or natural fibers, can be made compatible with sublimation printing by applying a special coating. This coating helps the fabric accept sublimation ink, although it may not achieve the same high-quality results as polyester fabrics.

MH offers a variety of polyester-based fabrics that are ideal for sublimation, ensuring excellent results for t-shirts, sportswear, and athletic gear.

Sublimation Printing Techniques

Sublimation printing techniques rely on specialized equipment and materials to achieve flawless results. The most widely used method is the heat press technique, where a printed transfer paper containing sublimation inks is placed onto the fabric. High heat and pressure are then applied, causing the dye to sublimate and transfer into the fabric fibers, resulting in a permanent, full-color print.

For larger production runs or oversized prints, manufacturers often turn to large format printers and calender heat presses. These machines are designed for large scale production, allowing for the efficient printing of banners, sportswear, and other products in large quantities. The choice of technique depends on the type of fabric—such as polyester blends, nylon, or spandex—and the specific requirements of the print, including size and detail.

Each method ensures that the dye is fully transferred into the fabric, producing prints that are vibrant, durable, and resistant to fading. By selecting the right sublimation printing technique, manufacturers can achieve consistent, high-quality results across a wide range of fabrics and applications.

Design Considerations for Sublimated Fabric

When creating designs for sublimated fabric, it’s important to tailor your approach to the unique characteristics of the sublimation process and the fabric itself. Since sublimation works best on synthetic fibers like polyester, designs should be developed with these materials in mind, taking into account the fabric’s texture, weave, and base color to ensure optimal results.

Digital printing software is a valuable tool for preparing artwork, allowing for precise color management and intricate detailing. To make the most of the sublimation process, designs should feature vibrant colors and sharp lines, as the process excels at reproducing complex patterns and gradients. It’s also essential to consider the intended use of the fabric—whether for apparel, home décor, or accessories—to ensure the design is both visually appealing and suitable for the final product.

By understanding the interplay between design, fabric, and the sublimation process, you can create printed items that are not only eye-catching but also perfectly suited to their purpose.

Why Choose Sublimation Fabric for Sportswear?

1. Vibrant Prints that Last

Sublimation printing offers a significant advantage over other printing methods when it comes to producing vibrant and detailed designs. Whether you’re designing custom t-shirts, soccer jerseys, or sports shorts, sublimation allows for full-color prints that won’t fade or crack.

This makes sublimation print fabric the preferred choice for manufacturers who want to create garments with bold, eye-catching designs, such as team logos, branding, or custom patterns.

2. Breathability and Comfort

Sublimated fabrics, particularly those made from polyester, are designed to be lightweight and breathable. This is essential for athletic apparel, which needs to support high-intensity activities without compromising comfort. The sublimation process does not add any extra weight to the fabric, ensuring that the garment remains light and airy—perfect for athletes in all sports.

3. No Restrictions on Design

Another benefit of using sublimation fabric is that it allows you to print all-over designs without worrying about seams or fabric lines. Unlike traditional screen printing, where designs are limited to certain areas, sublimation can cover the entire surface of the fabric, creating smooth and uninterrupted prints. This is particularly beneficial for designs that require full coverage, such as custom jerseys and training kits.

4. Moisture-Wicking and Durability

When it comes to sportswear, performance is key. Sublimated fabrics are known for their moisture-wicking properties, which help keep the wearer dry and comfortable by drawing sweat away from the body. This is especially important for sports like soccer, running, and basketball, where athletes exert themselves during intense activities.

Moreover, sublimated prints do not crack, peel, or fade over time, even after repeated washing. This ensures that the high-quality designs remain intact, maintaining the garment's aesthetic for years.

Choosing the Right Equipment for Sublimation Printing

Selecting the right equipment is a crucial step in achieving high-quality sublimation prints. The equipment must be compatible with the chosen fabric and capable of handling the desired print size and production volume. Heat presses are ideal for smaller runs and custom items, offering precise control over temperature and pressure to ensure vibrant, durable results. For larger projects, such as sportswear, banners, or flags, large format printers and calender heat presses provide the necessary width and efficiency for large scale production.

When evaluating equipment, consider features like adjustable temperature settings, consistent pressure application, and the ability to accommodate various fabric widths. Reliable, easy-to-maintain machines help minimize downtime and waste, ensuring smooth operation and consistent print quality. Investing in high-quality, compatible equipment is essential for producing sublimation prints that are bright, long-lasting, and resistant to fading—making them suitable for a wide range of applications, from athletic apparel to promotional banners.

By choosing the right sublimation printing equipment, you can deliver exceptional results that meet the demands of your customers and stand out in the marketplace.

Sublimation Fabrics Offered by MH Company

As a leading wholesale supplier of sportswear fabrics, MH Company provides an extensive range of fabrics ideal for sublimation printing. Our offerings are tailored to meet the needs of t-shirt manufacturers, soccer jersey manufacturers, and athletic apparel manufacturers. We understand the importance of quality, durability, and performance, which is why we only offer the best materials for sublimation.

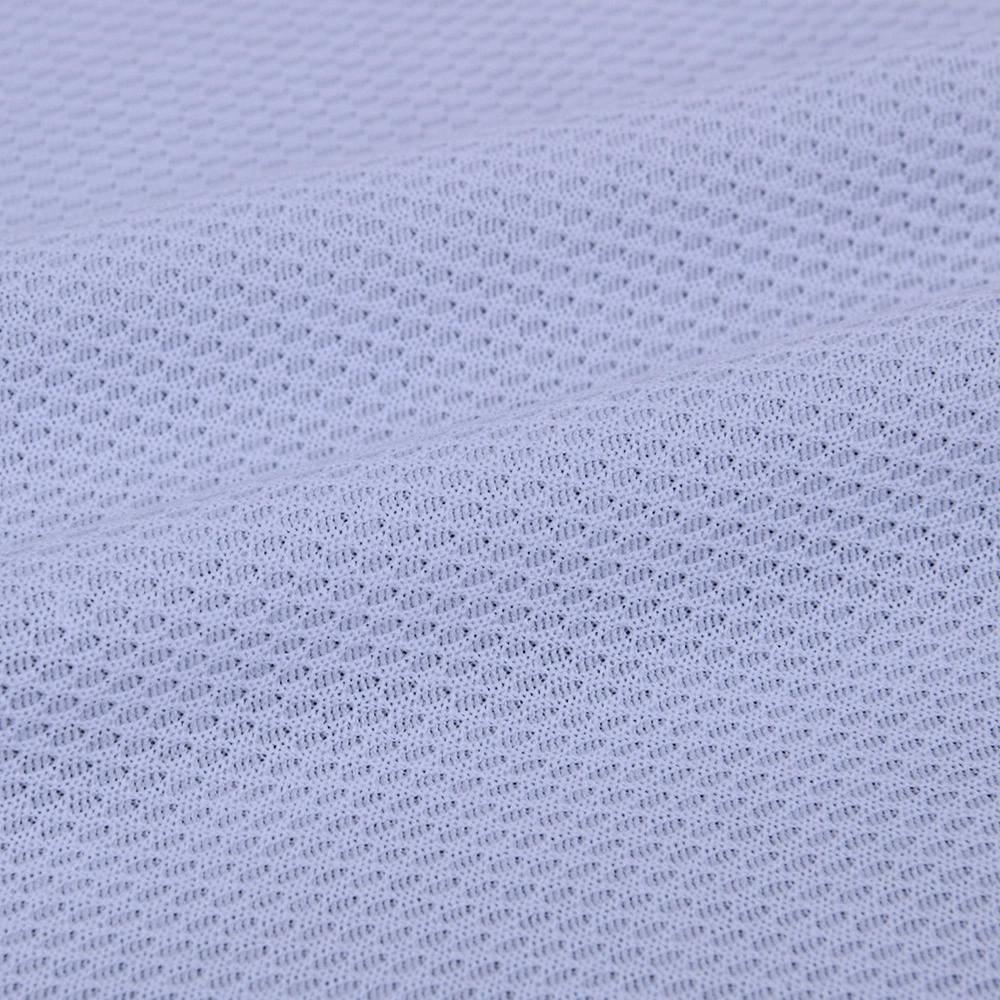

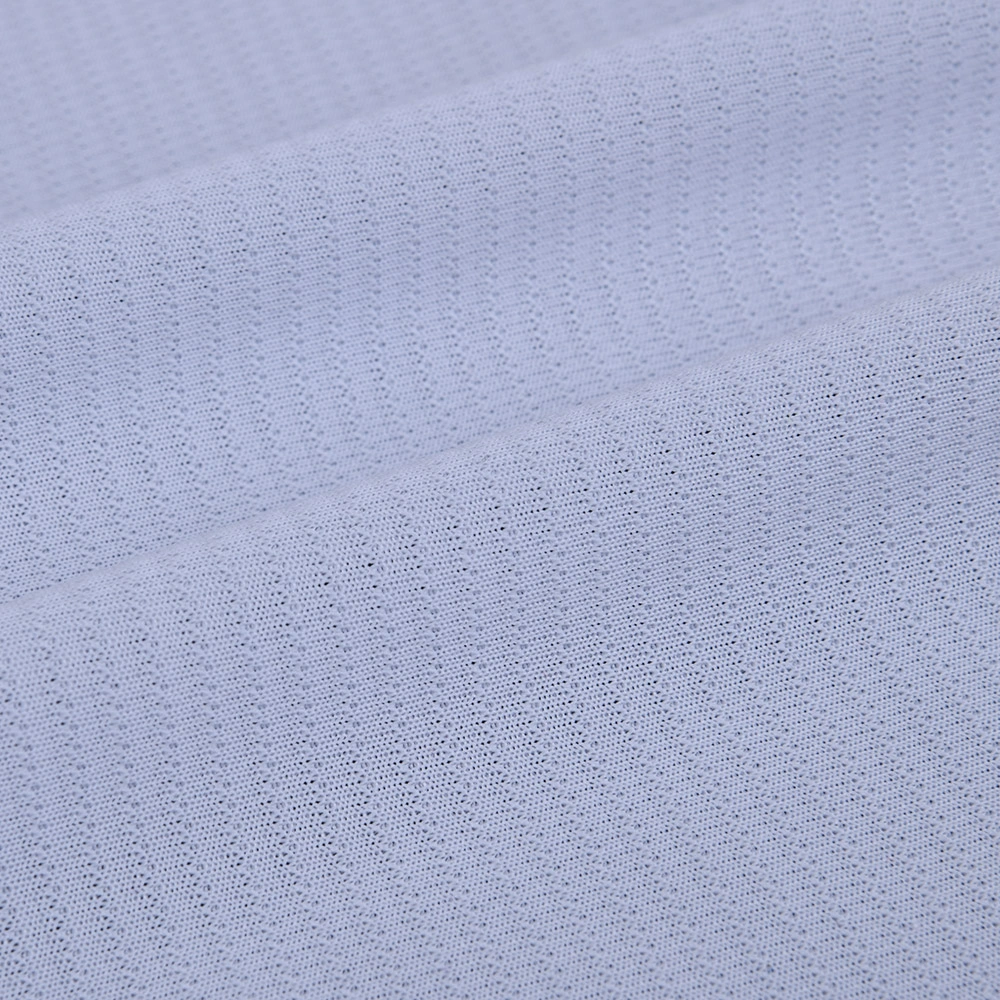

1. Sublimation Polyester Fabrics

Our 100% polyester fabrics are specifically designed to deliver optimal results for sublimation printing. Available in various weights and finishes, these fabrics are perfect for creating vibrant, full-color designs on sportswear, t-shirts, and more.

2. Polyester Blends with Spandex

For manufacturers looking to create athletic wear with a little extra stretch and flexibility, our polyester-spandex blends are an ideal choice. These fabrics provide the perfect combination of comfort and durability, making them perfect for jerseys, tights, and activewear.

3. High-Performance Sports Fabrics

For top-tier athletes, MH offers performance fabrics that incorporate moisture-wicking technology, anti-microbial properties, and UV protection. These fabrics are designed to handle the demands of intense physical activity while delivering high-quality sublimation results.

Conclusion: The Ideal Fabric for Sportswear Manufacturers

Sublimation fabric offers sportswear and t-shirt manufacturers the perfect combination of vibrancy, durability, and comfort. Whether you’re making custom jerseys, athletic gear, or team uniforms, sublimation fabrics ensure that your designs stay sharp and bright, even after repeated use.

With MH Company as your trusted supplier, you gain access to a range of premium sublimation fabrics that cater to every aspect of your production needs. Whether you're producing soccer jerseys, training wear, or performance fabrics, we’ve got you covered with high-quality textiles designed for the ultimate sublimation printing results.

Ready to take your sublimation designs to the next level? Request a sample or order today!