Thread Inserter: Essential Tool for Precision Sewing

Thread inserters represent critical equipment in modern textile manufacturing and tailoring operations. These specialized tools streamline the threading process for sewing machines, delivering enhanced productivity and operational efficiency across various applications.

A thread inserter functions as a precision instrument that guides thread through the eye of a sewing machine needle with accuracy and speed. This essential tool eliminates the manual threading process, reducing setup time and minimizing thread-related interruptions during production cycles.

Introduction to Thread Inserters

Thread inserters are essential tools for anyone passionate about sewing, whether working with sewing machines or practicing hand sewing techniques. These handy devices, often referred to as needle threaders, are designed to make threading needles quick and effortless. For those who spend a lot of time sewing, the process of threading a needle can be tedious and time-consuming, especially when working with fine thread or small needles. Thread inserters streamline this process, allowing users to focus more on their creative projects and less on the frustration of threading. By incorporating a thread inserter into your sewing routine, you can save valuable time and enjoy a smoother, more efficient sewing experience, regardless of your skill level.

Understanding Needle Threading

Needle threading is a crucial step in any sewing project, involving the precise act of passing thread through the tiny eye of a needle. This task can be particularly challenging due to the small size of the needle’s eye and the delicate nature of the thread. Many sewers, especially those with limited dexterity or vision, find manual needle threading to be a source of frustration. Needle threaders, or thread inserters, offer a practical solution by guiding the thread through the needle eye with ease. With the help of a thread inserter, the process of threading becomes much simpler and faster, allowing you to start sewing without unnecessary delays or errors. This tool is especially valuable for those who regularly work with a variety of needles and threads, ensuring consistent and reliable results every time.

Types of Thread Inserters Available

Manual Thread Inserters

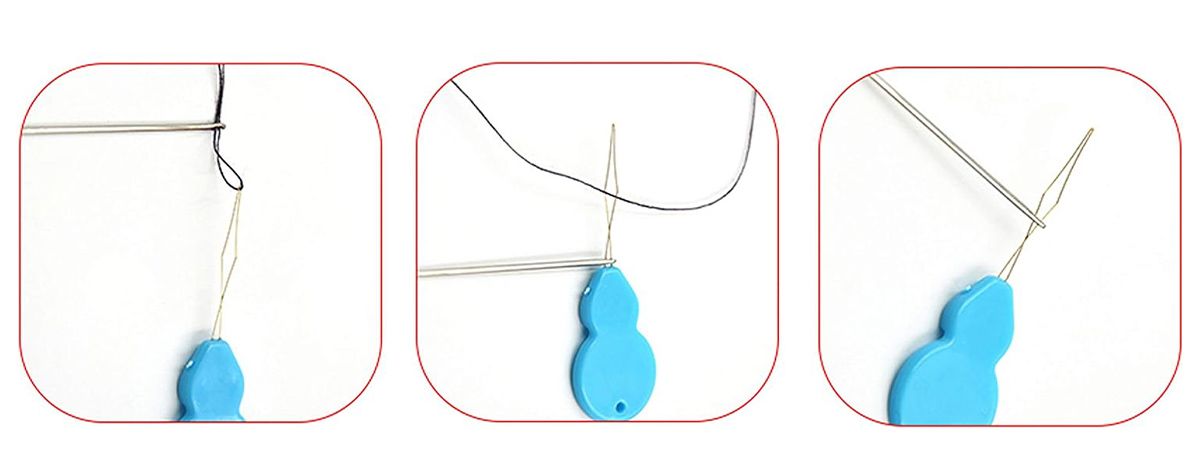

Manual thread inserters require operator intervention to complete the threading process. To use these tools, you must hold the needle or tool securely to ensure stability during threading. These tools feature a simple mechanism that guides the thread through the needle eye using a hook or wire system, simplifying the process of inserting the needle into the machine. When positioning the needle, a smooth slide motion is required to ensure the needle is correctly placed for threading. Manual needle threaders offer cost-effective solutions for small-scale operations and provide reliable performance for standard sewing applications.

Automatic Thread Inserters

Automatic thread inserters integrate directly with sewing machines to provide seamless threading functionality. These advanced systems detect needle position and automatically insert thread without manual intervention. Automatic needle thread inserter systems deliver superior efficiency for high-volume production environments and reduce operator fatigue.

Pneumatic Thread Inserters

Pneumatic systems utilize compressed air to drive the threading mechanism. These powerful tools handle heavy-duty applications and accommodate various thread types and needle sizes. Pneumatic thread inserters excel in industrial settings where consistent performance and durability are essential. They are designed to accurately place the needle or thread in the correct position during the threading process, ensuring precise and efficient operation.

Thread Inserter Features

Modern thread inserters come equipped with a variety of features designed to enhance the sewing experience. Many models offer automatic threading capabilities, using mechanisms such as wire loops, hooks, or pushers to guide the thread smoothly through the needle’s eye. Some thread inserters include built-in thread cutters, making it easy to trim thread to the perfect length before threading. Others feature ergonomic designs for comfortable handling, or storage compartments to keep your sewing area organized. For those using sewing machines, certain thread inserters are specifically engineered to be compatible with a wide range of machine types and needle sizes, ensuring versatility and convenience. With so many features available, there is a thread inserter to suit every sewing need, from basic hand sewing to advanced machine work.

Choosing the Right Thread Inserter

Selecting the ideal thread inserter depends on your specific sewing needs and preferences. If you primarily engage in hand sewing, a compact and portable thread inserter may be the best choice, offering convenience and ease of use wherever you sew. For those who rely on sewing machines, it’s important to choose a thread inserter designed for machine needles, ensuring compatibility and smooth operation. Consider the size and type of needles you use most often, as well as the material and construction of the inserter itself for durability and comfort. Additional features, such as built-in cutters or ergonomic grips, can further enhance your sewing experience. By evaluating these factors, you can find a thread inserter that is perfectly suited to your projects and sewing style.

Sewing Machine Compatibility

Ensuring that your thread inserter is compatible with your sewing machine is essential for achieving optimal results. Sewing machines vary in terms of needle types and sizes, and not all thread inserters are designed to work with every model. Some thread inserters are universal, capable of fitting a variety of machines and accommodating different needle sizes, while others are tailored to specific brands or models. Before purchasing a thread inserter, confirm that it matches your sewing machine’s requirements to avoid any issues during use. By selecting a compatible thread inserter, you can enjoy seamless threading, reduce downtime, and maintain the efficiency and quality of your sewing projects.

Benefits of Using a Thread Inserter

Increased Production Efficiency

Thread inserters significantly reduce machine downtime by eliminating manual threading procedures. Operators can maintain continuous workflow without interruptions, resulting in higher throughput and improved productivity metrics. The streamlined process allows for faster job changeovers and reduced setup times.

Enhanced Threading Precision

These tools ensure accurate thread placement through the sewing machine needle eye, eliminating threading errors that can cause production delays. Some thread inserters feature a specially designed groove that guides the needle or thread, allowing for more precise and consistent threading. Consistent threading accuracy reduces material waste and maintains quality standards throughout manufacturing processes.

Reduced Operator Strain

Manual needle threading requires fine motor control and visual precision, which can cause operator fatigue over extended periods. Thread inserters eliminate this physical demand, allowing operators to focus on other critical tasks while maintaining optimal performance levels.

Improved Thread Management

Advanced thread inserter systems include tension control features that maintain consistent thread delivery to sewing machines. Some thread inserters also feature a built-in cutter, allowing users to easily cut thread to the desired length for improved efficiency. This capability ensures uniform stitch quality and reduces thread breakage incidents during operation.

Applications Across Industries

Garment Manufacturing

Large-scale apparel production facilities utilize thread inserters to maintain high-speed manufacturing schedules. These tools make it easy to pull the thread through the needle eye, streamlining the threading process during garment production. They support rapid style changes and accommodate various fabric types and thread specifications required for different garment categories.

Automotive Textiles

The automotive industry relies on thread inserters for upholstery and interior component manufacturing. These applications demand precise threading for heavy-duty materials and specialized thread types used in automotive applications.

Technical Textiles

Manufacturing technical textiles for industrial applications requires consistent threading accuracy. Thread inserters support the production of specialized fabrics used in filtration, medical devices, and protective equipment manufacturing.

Custom Tailoring Operations

Professional tailoring businesses benefit from thread inserters when handling multiple projects with varying thread requirements. These tools enable efficient transitions between different thread colors and types while maintaining professional quality standards.

Maximizing Threading Efficiency in Your Operations

Thread inserters deliver measurable improvements in sewing machine productivity and operational efficiency. These precision tools reduce setup time, minimize threading errors, and support consistent production quality across various textile applications.

Professional-grade thread inserters accommodate different needle threader requirements and integrate seamlessly with existing sewing machine configurations. The investment in quality threading equipment translates directly to improved production metrics and reduced operational costs.

Selecting the appropriate thread inserter type depends on production volume, thread specifications, and operational requirements. Manual systems provide cost-effective solutions for moderate-volume operations, while automatic systems deliver superior efficiency for high-production environments.

Any questions about thread inserters or our return policies are handled promptly to ensure customer satisfaction.