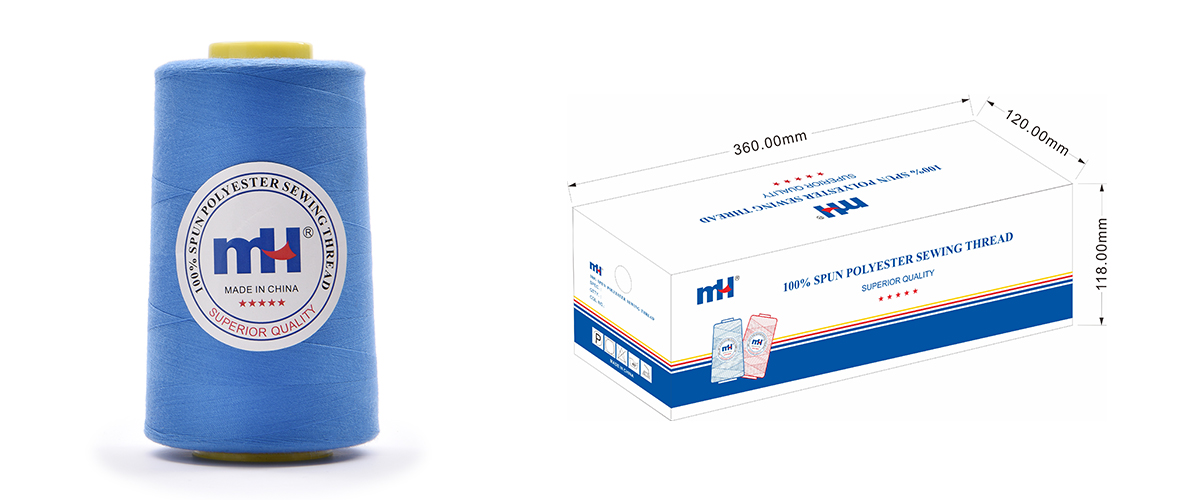

30S/2 Cone Thread

Cone Thread

| Material: | 100% polyester |

| Count: | 30S/2 |

| Weight: | 70-150g |

| Color: | Color Card Available |

| Logo & Packaging: | 12pcs/box, 10boxes/carton |

| MOQ: |

|

| Certification: |

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

MH Sewing Thread Factory

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Product Details

Key Technical Data

| Tex (T) | Tickets Size (TKt) | Cotton Count (s) | Average Strength (cN) | Average Strength(g) | Elongation Min-Max (%) | Needle Size | |

|---|---|---|---|---|---|---|---|

| Singer | Metric | ||||||

| 18 | 160 | 60/2 | 666 | 679 | 8.5-13.5 | 9-11 | 65-75 |

| 24 | 140 | 50/2 | 850 | 867 | 9.5-14.5 | 9-11 | 65-75 |

| 30 | 120 | 40/2 | 1020 | 1040 | 10-15 | 11-14 | 75-90 |

| 30 | 120 | 60/3 | 1030 | 1050 | 10-15 | 12-14 | 75-90 |

| 40 | 80 | 30/2 | 1370 | 1397 | 10-15.5 | 14-18 | 90-110 |

| 45 | 70 | 40/3 | 1640 | 1673 | 10-15.5 | 14-18 | 90-110 |

| 60 | 50 | 20/2 | 2120 | 2162 | 10.5-16 | 16-19 | 100-120 |

| 90 | 30 | 20/3 | 3180 | 3244 | 11.5-16.5 | 18-21 | 110-130 |

Remarks:

1. The recommended needle size is for reference only; the user should adjust it according to the sewing material and usage.

2. The technical information listed above is based on the current average and should be used only as an indication before final use.

Standard Packaging

| Specification | Length | Quantity per Carton | 40" HFCL/68m3 |

|---|---|---|---|

| 60S/2 | 5000 Yards | 120PCS/10 BOX | 13250 DOZ |

| 50S/2 | 5000 Yards | 120PCS/10 BOX | 11100 DOZ |

| 40S/2 | 4000 Yards | 120PCS/10 BOX | 12500 DOZ |

| 40S/2 | 5000 Yards | 120PCS/10 BOX | 11100 DOZ |

| 29S/2 | 5000 Yards | 120PCS/10 BOX | 7590 DOZ |

| 40S/3 | 5000 Yards | 120PCS/10 BOX | 9000 DOZ |

| 20S/3 | 5000 Yards | 60PCS/10 BOX | 4350 DOZ |

Washing Color Fastness

| Temper Ature (°C) | Time (min.) | ECE Detergent (g/l) | Liquor Volume (ml) | Sodium Perborate (g/l) | Steel Balls | Color Change/ Staining |

|---|---|---|---|---|---|---|

| 50 | 30 | 4 | 150 | 1 | 25 | Grade 4 |

Remarks:

Technical information listed above is based on current average and should be taken only as indication before the final usage.

Application

| Specification | Length |

|---|---|

| 20S/2 | Jeans, shoes, caps, leather products.etc |

| 20S/3 | Jeans, shoes, handbags, leather products, etc |

| 20S/4 | Packing bags, leather products, hand bags, shoes, etc. |

| 20S/6 | Packing bags, canvas |

| 20S/9 | Jeans, leather products, handbags. |

| 30S/2 | Suits, bedcover, bedsheet, sportswear, notions, sewing crafts and notions, etc |

| 30S/3 | Tents, jeans, leather products, shoes, caps, baby clothes, etc |

| 40S/2 | Suits, bedcover, bedsheet, sportswear, notions, sewing craft and notions etc. |

| 40S/3 | Heavy quilt bedcover, glove, toys, protective clothing, sewing craft and notions, shoes, etc. |

| 50S/2 | Knitting garment, blouses, suit-dress, silks,underwear, etc. |

| 60S/2 | Knitting garment, suit-dress, overlocking thread, handkerchief, underwear, etc. |

| 60S/3 | Knitting garments, fashionable dress, suit-dress, sportswear, sewing craft and notions, etc. |

| 80S/3 | High quality shirt and national dress |

MH products have undergone rigorous testing by Testex AG and have been certified with the OEKO-TEX® STANDARD 100 label, ensuring they are free from harmful chemicals and safe for sensitive skin. We are committed to providing you with high-quality, safe, and eco-friendly products.

Download the Testex AG test report: Click here

Contact MH today to get the latest FOB/CIF prices and free samples!

Customization Services

Color Customization

Discover the Polyester Sewing Thread Color Chart, showcasing a stunning selection of over 800 vibrant colors. This versatile and comprehensive collection allows for flawless color matching, as it features actual thread samples. Choose your desired polyester threads with confidence and precision..

Yarn Count Customization

Our quality sewing thread products are available in a wide range of options, including 20/2, 20/3, 30/2, 30/3, 40/2, 42/2, 40/3, 50/2, 50/3, 60/2, 60/3, and more. Choose and find the perfect option that suits your needs!

Packaging + Logo Customization

We offer a wide range of packaging type options, spanning from 1000 to 20000 yards, or 0.5kg to 2.0kg/cone.

Support ODM/OEM Customization

Other Thread Products

We offer additional polyester thread options: corespun polyester sewing thread, high tenacity polyester sewing thread, cotton sewing thread, bag closing thread, recycled sewing thread, anti-UV sewing thread, waterproof sewing thread, fire-retardant sewing thread, High extension flex sewing thread, water soluble sewing thread, sewing thread sets.