Woven Fusing Interlining Fabric

75D*150D Twill Woven Fusible Interlining

| Material: | 100% polyester |

| Width: | 150cm |

| Yarn Count: | 75D*150D |

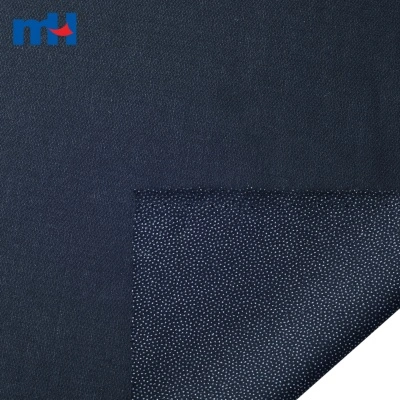

| Glue powder: | PA, PA+PES, PES |

| Color: | Black, white or other colors |

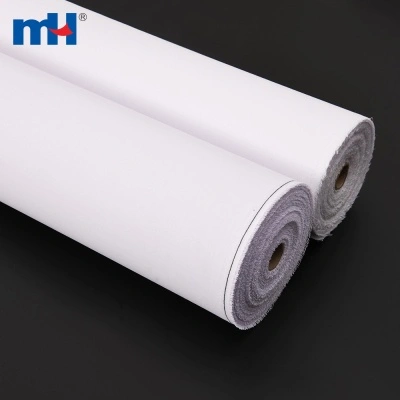

| Packaging: | 100m/roll, 150m/roll, according to customer's need |

| MOQ: |

|

| Certification: | OEKO-TEX® CERTIFIED  |

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

MH Woven Interlining Factory

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Product Details

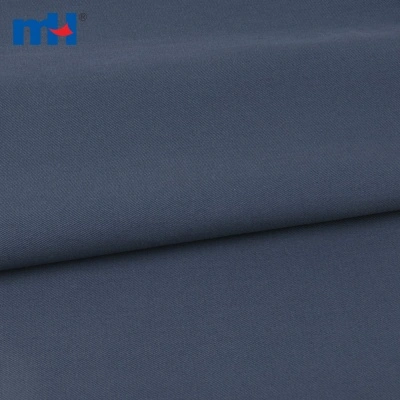

Twill woven interlining fabric is a structured support fabric made using a twill weave pattern, which is characterized by diagonal lines on the surface. This weaving technique results in a denser, more durable interlining that is ideal for garments requiring added strength, resilience, and shape retention. Compared to plain woven interlining, twill interlining offers greater thickness and drape, making it suitable for heavier or tailored garments.

Twill woven interlining fabric is widely used in structured garments such as suit jackets, blazers, coats, and trousers, particularly in areas like front panels, lapels, waistbands, and chest pieces. Its strength and ability to retain shape also make it ideal for skirts with defined waistlines, heavyweight shirts, uniforms, and fashion accessories like belts, caps, and structured bags.

Fusing Temperature: 130-150℃

Fusing Pressure: 1.5-2.5kg/cm2

Fusing Time: 12-15s

Woven interlinings are woven surfaces in the known sense.

Due to their structure, they are not easily damaged during use and cleaning.

Interlinings are primarily used for imparting strength/support, stability and shape retention.

It's post treated with bleaching, dyeing, sizing and PA double-point gluing, suitable for ironing on the front and back piece of the suit, jacket and coat, which make the cloth more stylish, crisp, durable and warm.

Customization Services

Composition Customization

Width Customization

Specification Customization

Handfeel Customization

Glue Customization

Weight Customization

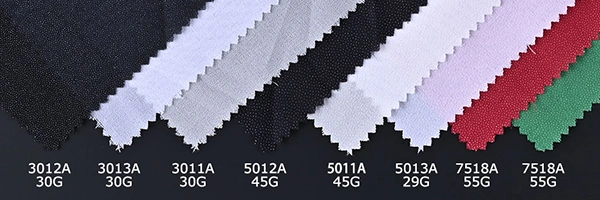

Fashion Interlining Weave Type

Fusing Conditions

| Type | Machine Temperature | Fusing Temperature | Pressure | Time |

| Continuous Press | 130~150℃ | 127~143 ℃ | 1.5~2.5kg/cm2 | 12~15S |

| Flat Bed Press | 130~150℃ | 127~143℃ | 0.8~1.5kg/cm2 | 12~15S |

MH Plain Woven Interlining Feature

-

Air PermeabilityThe interlining offers excellent breathability, ensuring air circulation even with lightweight fabrics, making it ideal for light, flowy summer clothing.

-

Color OptionsAvailable in classic black, white, and customizable colors to match various fabrics.

-

Soft HandfeelGentle on the skin, preventing irritation, and meeting high-end fashion standards.

-

Eco-FriendlyOeko-Tex 100 certified, meeting international standards for eco-conscious markets like Europe and North America.

Machine

Packaging

Usage

Used for suits, overcoat, jacket, windbreaker jacket, etc.