Acetal Copolymer (POM) Resin for Molded Zipper Teeth

- Latest

Acetal Copolymer (POM) Resin for Molded Zipper Teeth

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

Product Overview

Acetal Copolymer (POM) is a premium engineering thermoplastic widely selected by zipper manufacturers for producing high-quality molded zipper teeth. It delivers an excellent balance of mechanical strength, low friction, and dimensional stability, helping zippers run smoothly and remain durable after repeated use.

At MH, this POM acetal copolymer is used as a key raw material for resin zipper teeth, supporting consistent molding performance and reliable downstream dyeing for custom colors.

Features

- Excellent Dyeability: Easily dyed into vivid and uniform shades, suitable for fashion, luggage, footwear, and workwear zipper applications.

- High Mechanical Strength: Strong and rigid structure helps zipper teeth resist deformation, chipping, and breakage.

- Low Friction & Smooth Sliding: Naturally low coefficient of friction supports smooth zipper operation and reduces sticking.

- Dimensional Stability: Maintains precise tooth geometry during injection molding and long-term use.

- Wear & Fatigue Resistance: Performs reliably under frequent open-close cycles.

- Chemical & Moisture Resistance: Suitable for humid environments and many common chemicals.

- FDA-Compliant Grades Available: Options available for applications requiring elevated safety and quality standards.

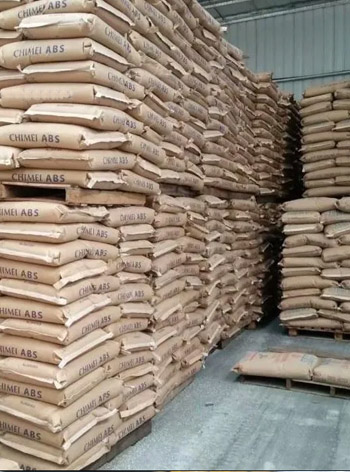

Packaging

Packed in 25 kg sealed industrial bags with moisture-proof inner lining, ensuring the POM acetal copolymer granules remain clean, dry, and stable during transportation and storage.

Usage

- Injection-molded resin (plastic) zipper teeth

- Garment zippers

- Bag & luggage zippers

- Footwear zippers

- Outdoor & workwear zippers

- Specialty and colored zippers

Why Acetal Copolymer (POM) for Zipper Teeth?

Molded zipper teeth require high precision, smooth operation, and durability. POM acetal copolymer is widely adopted as the industry-standard resin because it supports:

- Accurate tooth geometry and stable molding

- Low-friction, smooth zipper running

- Durability under repeated use

- Reliable dyeing for consistent color matching