Non Woven Fusible Interlining

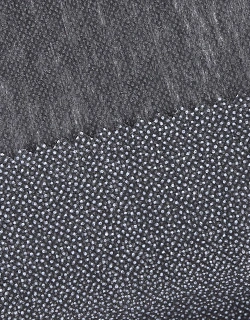

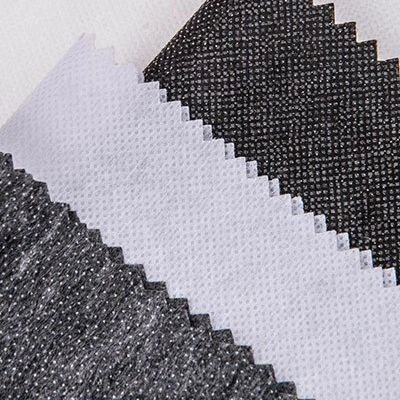

Double Dot Non Woven Fusible Interfacing

- Model6403-0127

| Material: | 100% Polyester |

| Width: | 150cm |

| Weight: | 27g/m2 |

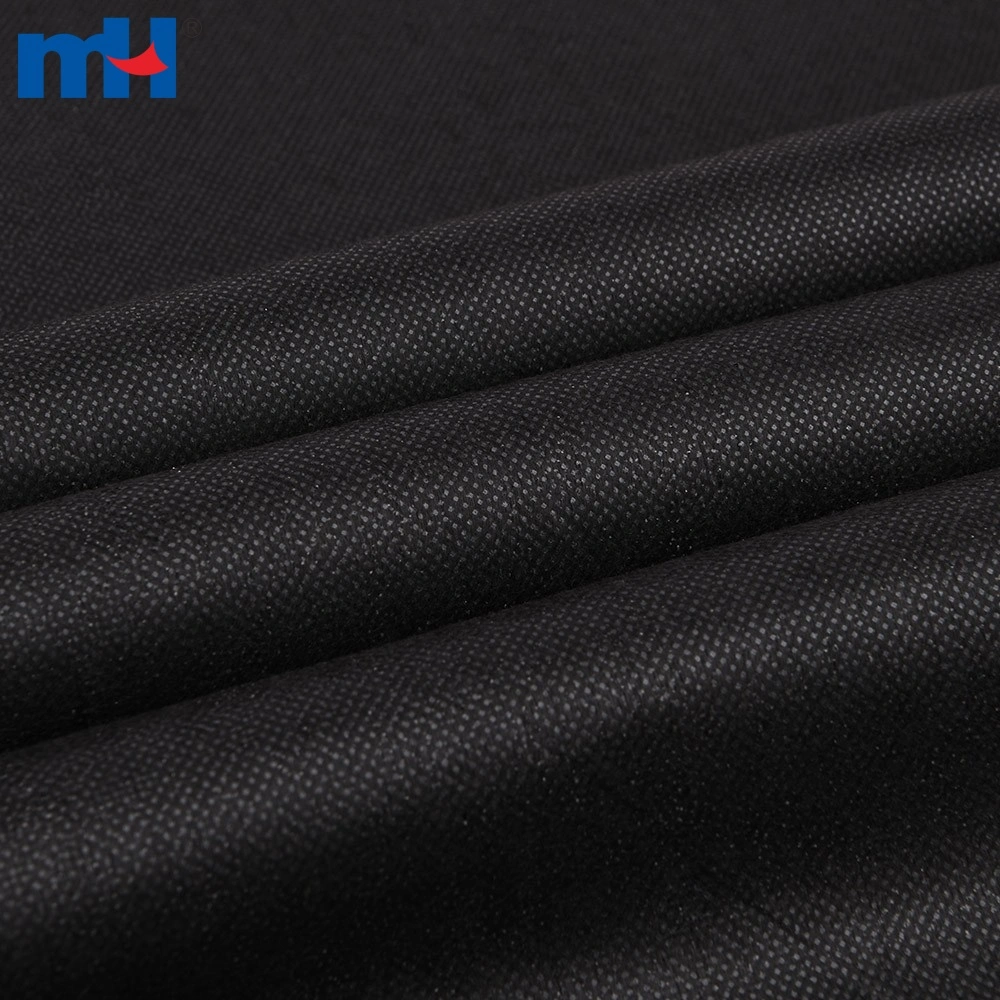

| Color: | Black, white, grey |

| Glue Powder: | PA |

| Packaging: | 50m/roll, 100m/roll |

| MOQ: |

|

| Certification: | OEKO-TEX® CERTIFIED  |

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

MH Non-woven Interlining Factory

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Product Details

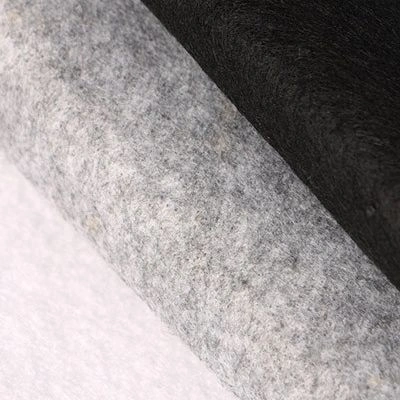

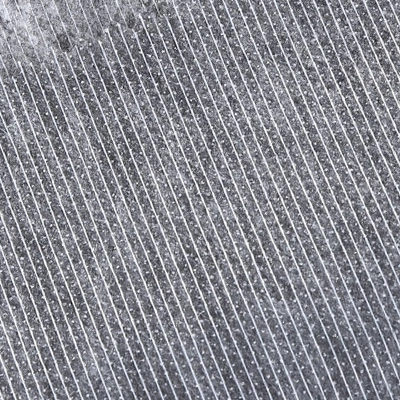

Thermal Calendaring Double Dots Nonwoven Fabric is a specialized type of nonwoven fabric that uses a double-dot bonding pattern created through thermal calendaring. This process enhances the fabric's strength, durability, and versatility, making it suitable for a wide range of applications in garment, hygiene, medical, filtration, and industrial sectors.

Upon the application of heat, the adhesive melts and bonds securely to the fabric. The double dot pattern ensures an even distribution of the adhesive, resulting in superior bonding strength and enhanced durability post-fusion.

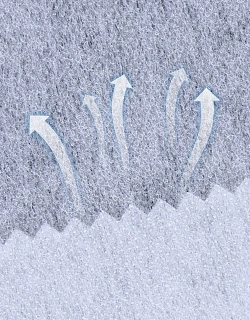

Nonwoven interfacings are distinguished by their softness, flexibility, and adaptability to various shapes, rendering them exceptionally suitable for a wide range of garment construction applications.

It is frequently employed in the collars, cuffs, facings, and other garment sections to impart crispness and structure.

Customization Services

Composition Customization

Techniques Customization

- Thermal Calendaring Double Dots Nonwoven Interlining

- Thermal Calendaring Powder Spraying Nonwoven Interlining

- Thermal Calendaring Stitch Bond Nonwoven Interlining

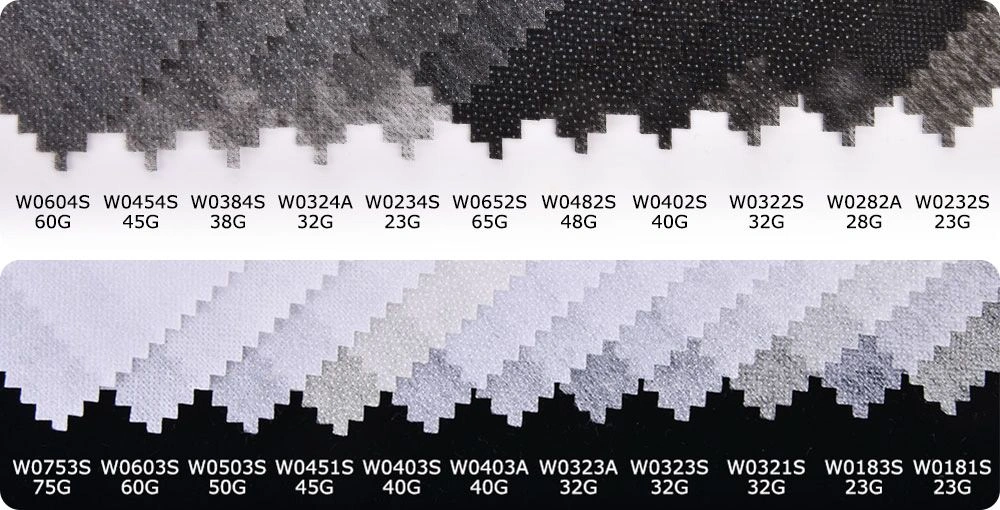

Weight Customization

Packing Customization

Fusing Conditions

| Type | Machine Temperature | Actual Temperature | Pressure | Time |

| Continuous Press | 130~150℃ | 127~143 ℃ | 1.5~2.5kg/cm2 | 12~15S |

| Flat Bed Press | 130~150℃ | 127~143℃ | 0.8~1.5kg/cm2 | 12~15S |

MH Thermal Calendaring Nonwoven Interlining Feature