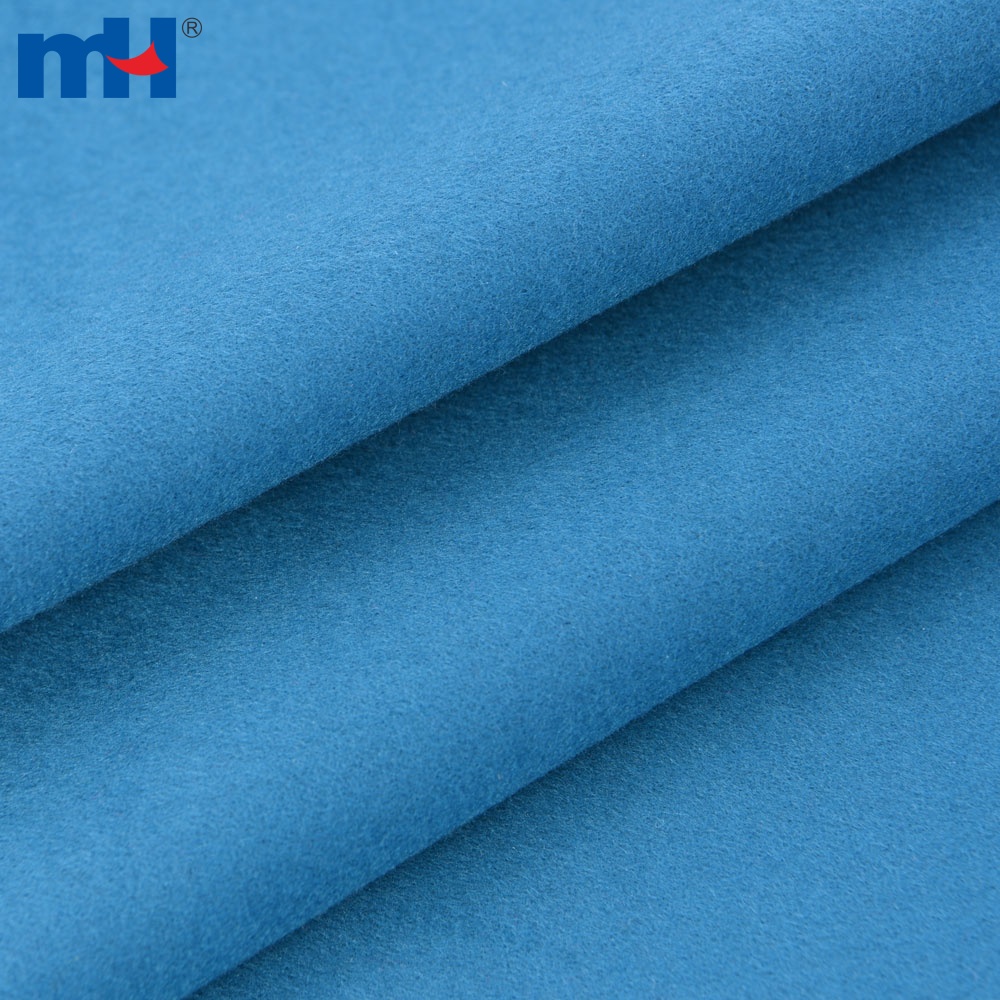

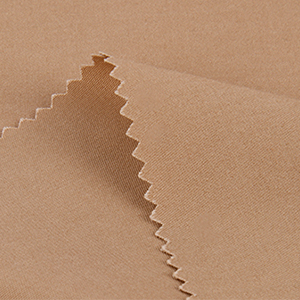

Double-sided brushed T/R suiting fabric

Double-sided Brushed 90/10 T/R fabric

- Model8152-0007

| Material: | 90% Polyester + 10% Viscose |

| Spec: | 300D*(32S/2+40D) |

| Width: | 150cm |

| Weight: | 380g/m2 |

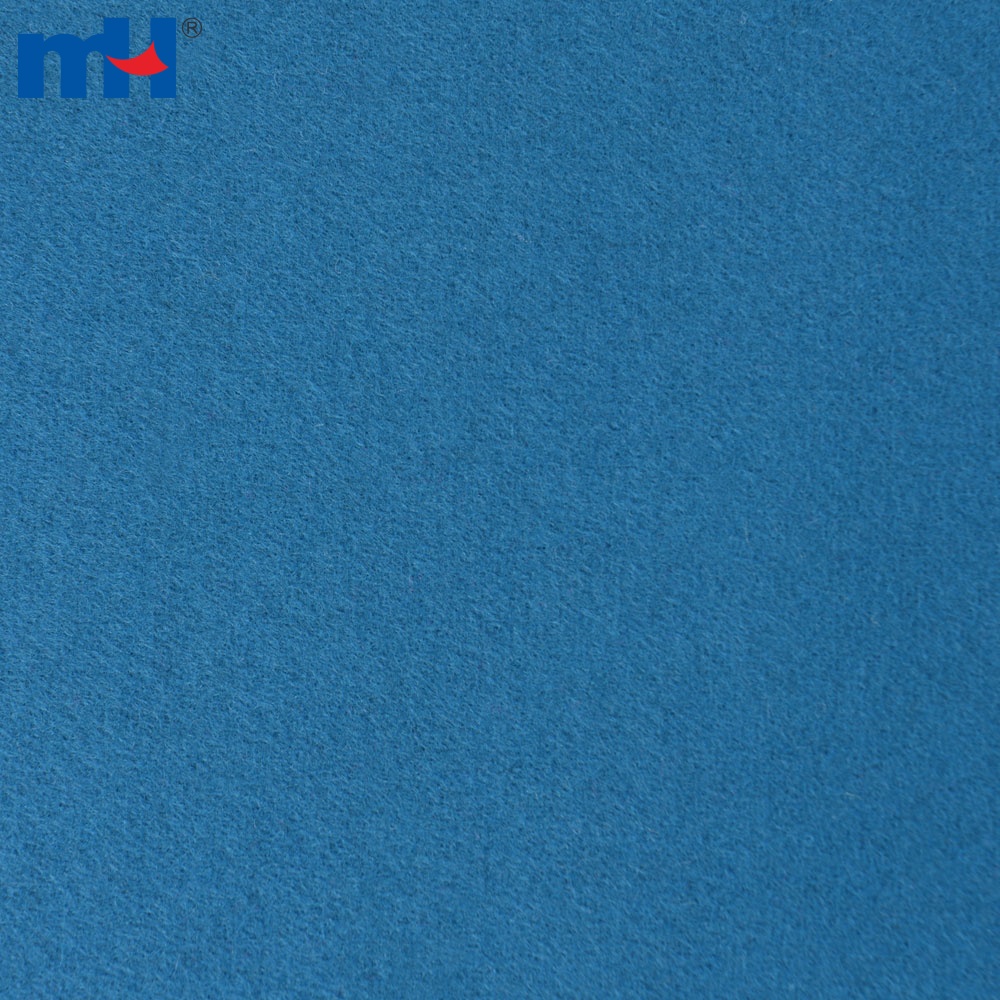

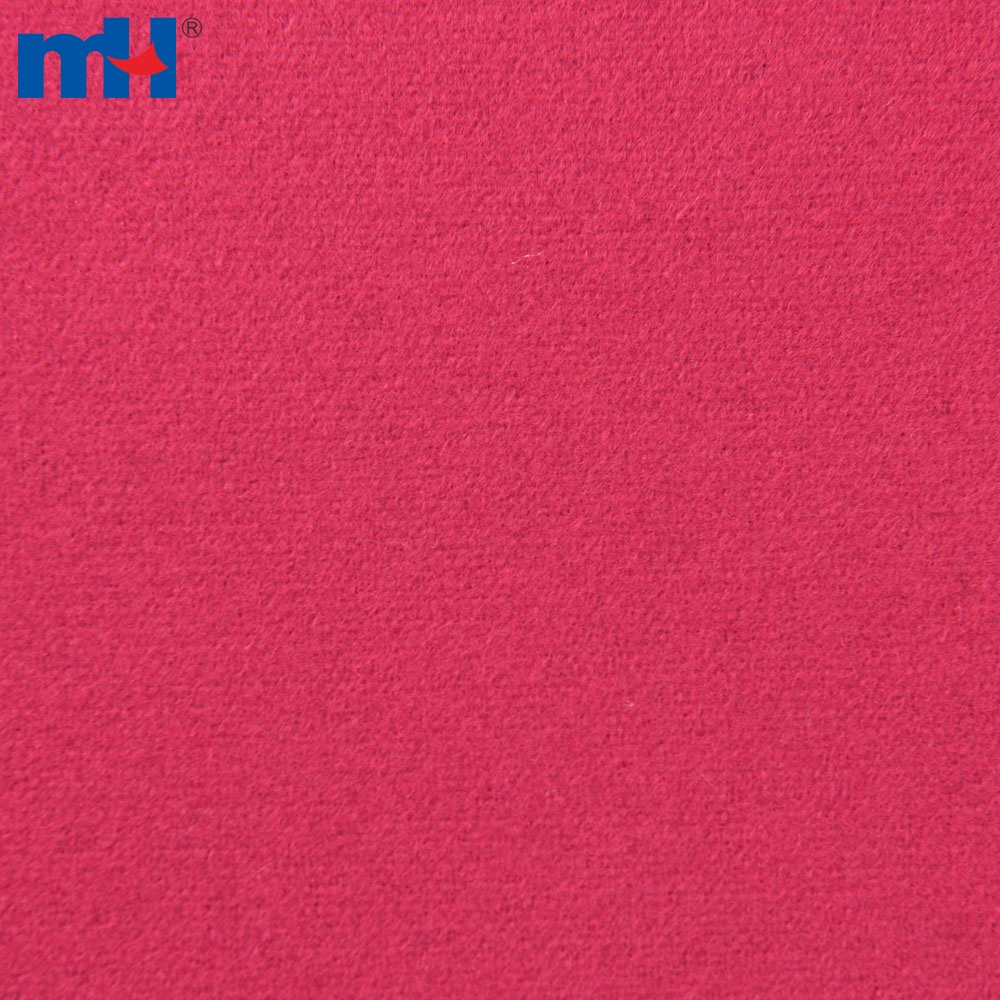

| Color: | Color Card Available |

| Packaging: | 30m/roll, or 50m/roll |

| MOQ: |

|

| Certification: | OEKO-TEX® CERTIFIED  |

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

Woven Fabric Factory

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Product Details

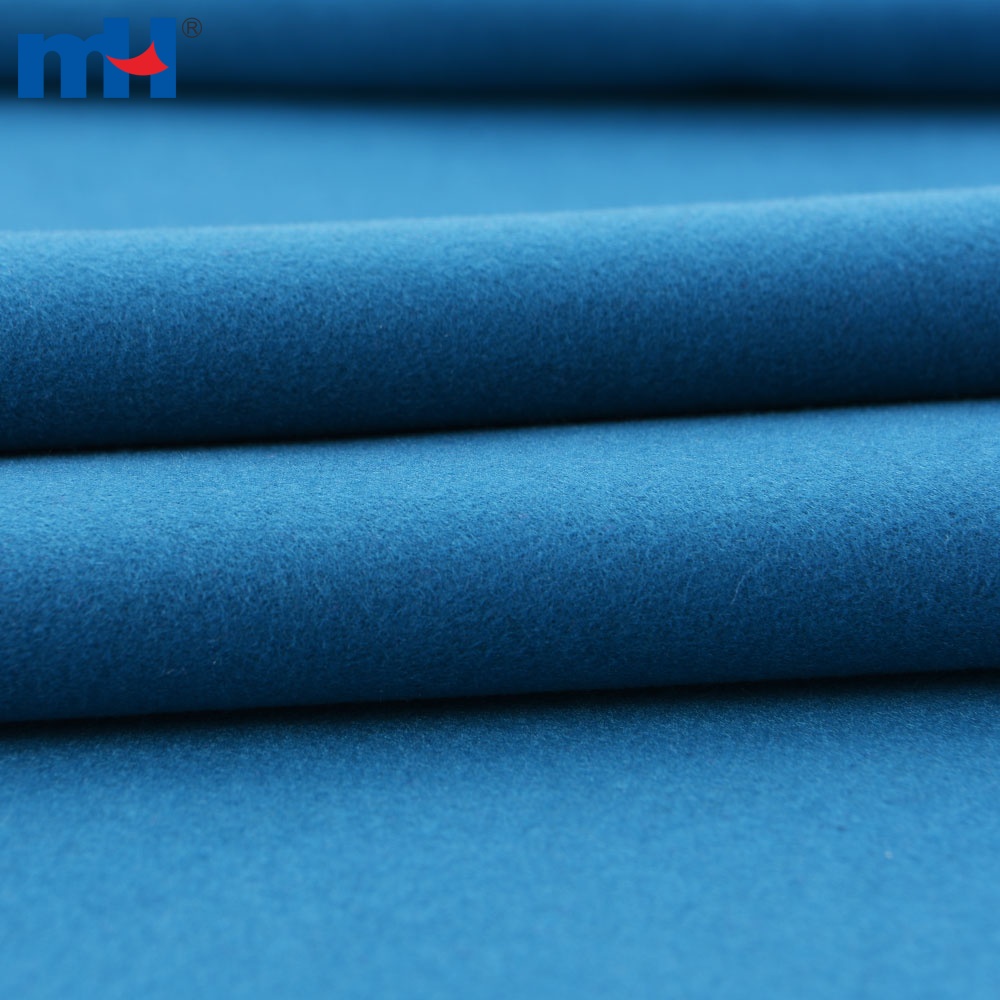

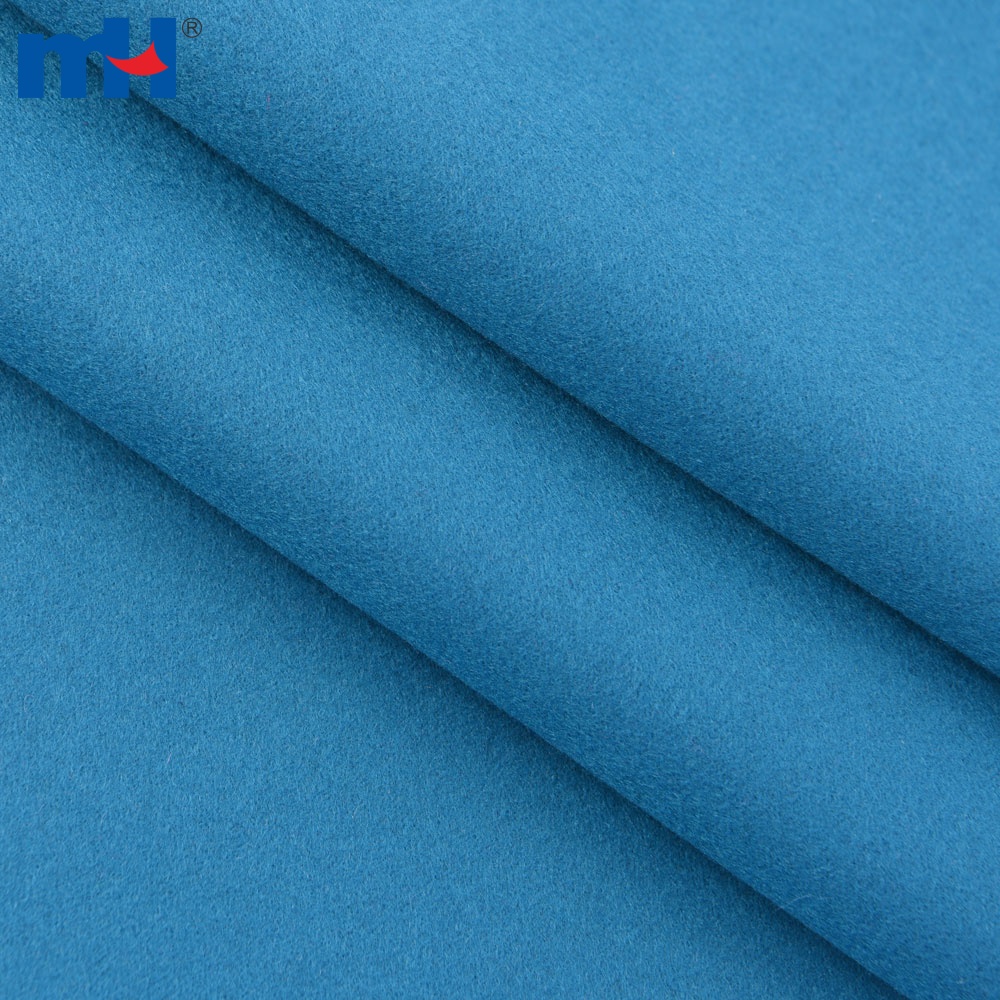

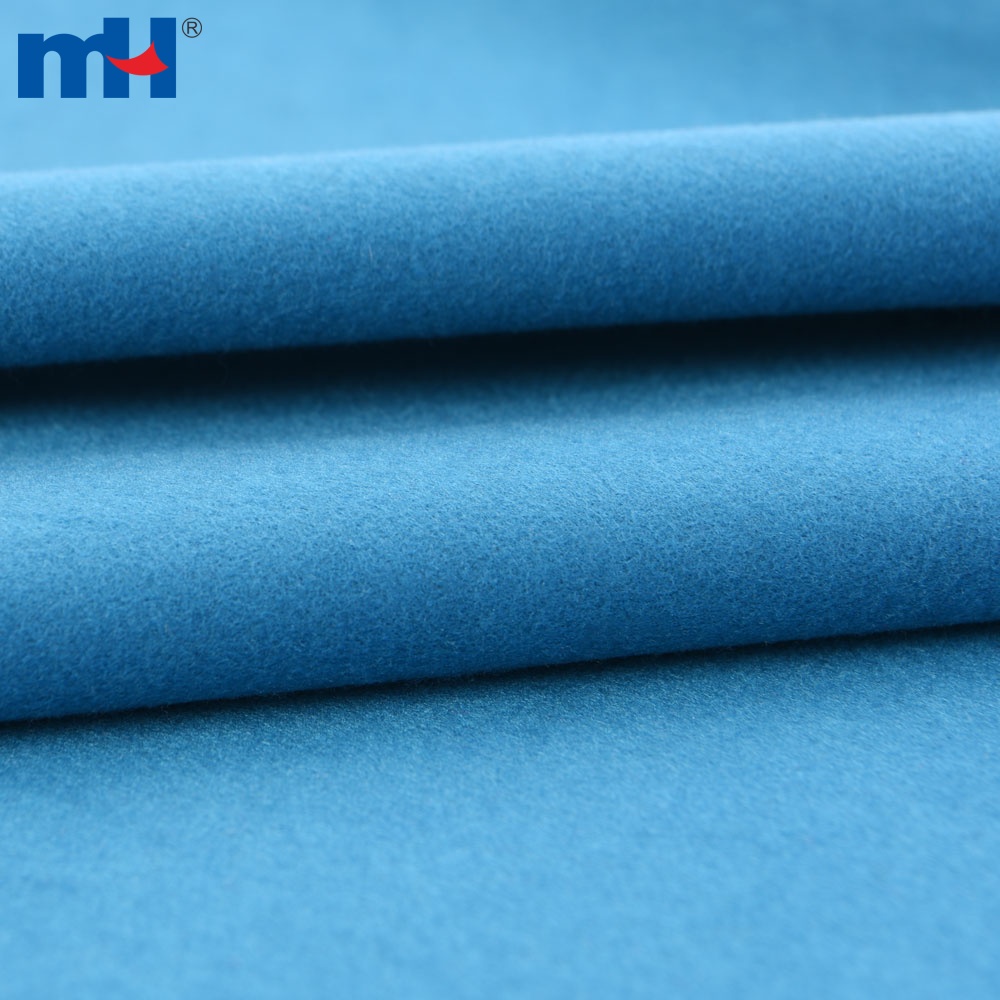

T/R Polyester/Viscose 90/10 Double-Sided Brushed Fabric is a textile made from a blend of 90% polyester and 10% viscose rayon, with both sides of the fabric undergoing a brushing process. This creates a soft, warm, and luxurious texture on both sides, making it ideal for applications where comfort and warmth are priorities.

Features

- Double-Sided Brushing: Both sides of the fabric are brushed, resulting in a soft and velvety texture on both surfaces. This enhances comfort and makes the fabric feel premium.

- High Durability: The 90% polyester content ensures excellent strength, wear resistance, and longevity, making it suitable for heavy use.

- Soft and Comfortable: The 10% viscose component adds softness and improves the fabric's skin-friendliness, balancing the stiffness of polyester.

- Enhanced Warmth: The double-sided brushing creates a layer of fine fibers on both sides, trapping air and providing excellent insulation, making it perfect for colder climates.

- Wrinkle Resistance: Polyester's natural wrinkle-resistant properties ensure the fabric maintains a neat and polished appearance.

- Moisture Absorption and Breathability: Viscose fibers contribute to better moisture absorption and breathability, improving overall comfort.

- Luxurious Appearance: The brushed finish on both sides gives the fabric a high-end, cozy look and feel, suitable for premium applications.

Applications

- Winter Clothing: Ideal for coats, jackets, scarves, and other garments that require warmth and softness.

- Home Textiles: Commonly used for blankets, throws, and cushion covers, offering a cozy and luxurious touch.

- Loungewear: Perfect for pajamas, robes, and other casual wear due to its comfort and warmth.

- Professional Attire: Suitable for uniforms and workwear that require durability and a polished appearance.

MH TR Fabric Feature

Customization Services

Material Customization

Width Customization

Specification Customization

| Specification | Dyeing process |

| TR 80/20 32S*32S 130*70 160GSM 57/58" | Beck Dye |

| TR 85/15 32S*32S 133*72 165GSM57/58" | Beck Dye |

| TR 85/15 32*32 133*72 170GSM 57/58" | Beck Dye |

| TR 85/15 32S*32S 133*72 165GSM57/58" | Continue Dye |

| TR 85/15 32*32 133*72 170GSM 57/58" | Continue Dye |

| TR 80/20 32S/2*32S/2 56*48 175GSM 57/58" fabric hem with english letters pattern |

Beck Dye |

| TR 80/20 32S/2*16S 56*48 175GSM 57/58" fabric hem with english letters pattern |

Beck Dye |

| TR 85/15 31S*31S 102*68 136GSM 57/58" | Beck Dye |

| TR 80/20 31S*31S 84*76 125GSM 57/58" | Beck Dye |

| TR 80/20 31S*31S 104*70 140GSM 57/58" fabric hem with english letters pattern |

Beck Dye |

| TR 85/15 21*21 102*52 185GSM 57/58" | Beck Dye |

| TR 80/20 21S*21S 104*74 210GSM 57/58" | Beck Dye |

| TR 80/20 21S*21S 100*84 225GSM 57/58" | Beck Dye |

Color Customization

MH provides T/R fabric color cards, offering a wide range of customizable color options.

Packaging Customization

Factory introduction

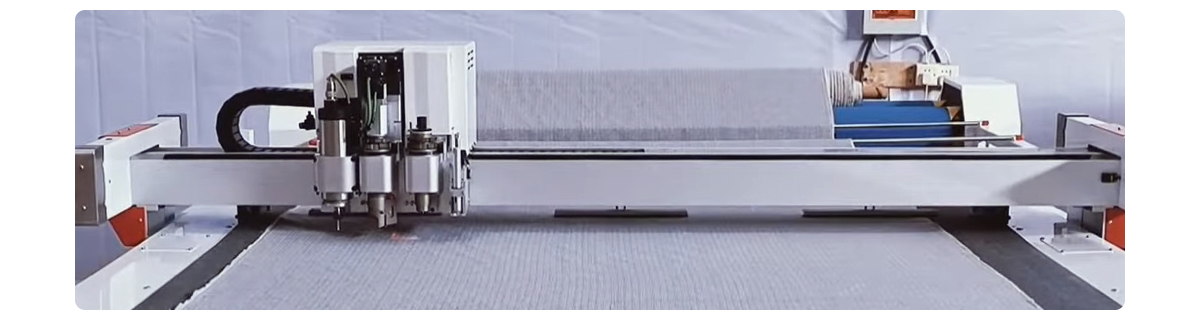

Weaving

MH’s products are made by China’s advanced air jet non-shuttle looms, which not only improve production efficiency, but cut cost and save energy as well. Besides, finished fabric has few thread residues, and are tidy, flat.

Dyeing

The grey fabric are dyed by automatic temperature control systems and high-temperature high-pressure dyeing equipments. Finished fabric have even surface, bright color and excellent color fastness, and the color difference meet Europe standard.

High temperature setting

Imported setting machines help fabrics dry quickly, keeping them flat, even, and stable in width.

Fabric inspection

During producing, inspection process is in each process, from raw yarn, grey fabric, to dyed and finished fabric, only the qualified fabric which meet Europe standard can be shipped out to customers.

Workwear Uniform Fabrics: Features and Applications

| Feature | Recommended Fabrics | Specific Industry Applications |

| Durability & Tear Resistance | Polyester-cotton blends, Canvas | Heavy manufacturing, automotive assembly, school uniforms for outdoor or sports activities |

| Water & Stain Resistance | Coated polyester, Oxford fabric | Outdoor construction, landscaping, rain-resistant school uniforms or activity wear |

| Flame Resistance & Anti-Static | Flame-retardant fabrics, Conductive fiber fabrics | Chemical plants, welding workshops |

| Comfort & Breathability | 100% cotton, Moisture-wicking fabrics | Hospitality, healthcare uniforms, school uniforms |

| Warmth & UV Protection | Fleece fabrics, UV-resistant fabrics | Winter road maintenance, forestry, winter school uniforms for colder regions |

| Washability & Color Stability | Polyester-cotton blends, Dyed cotton | Hotel housekeeping, food processing |