1025HF Chemical Bonded Interlining Fabric

Non-Woven Fusible Interlining Fabric

- Model6401-0097

| Material: | 100% Polyester |

| Width: | 90cm |

| Weight: | 20-150gsm |

| Hand Feeling: | Hard |

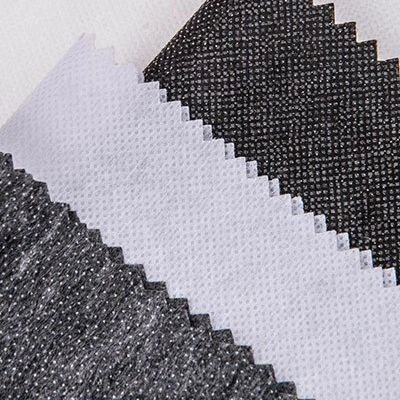

| Fusible Glue: | LDPE |

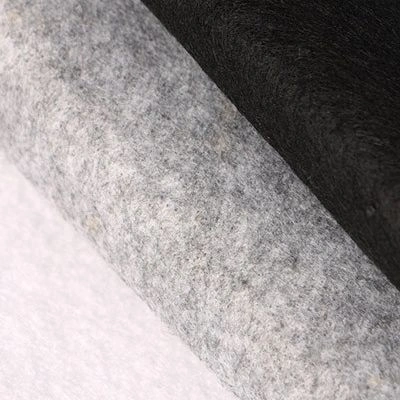

| Color: | Super white, white, black, etc. |

| Packaging: | 50m/roll, 100m/roll, 50yds/roll, 100yds/roll |

| MOQ: |

|

| Certification: | OEKO-TEX® CERTIFIED  |

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

MH Non-woven Interlining Factory

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Product Details

Chemical-bonded nonwoven interlining fabric is a versatile material widely used in the textile, apparel, and industrial sectors. It is created by bonding fibers together using chemical adhesives, resulting in a durable and functional fabric.

Technics: Chemical-bonded

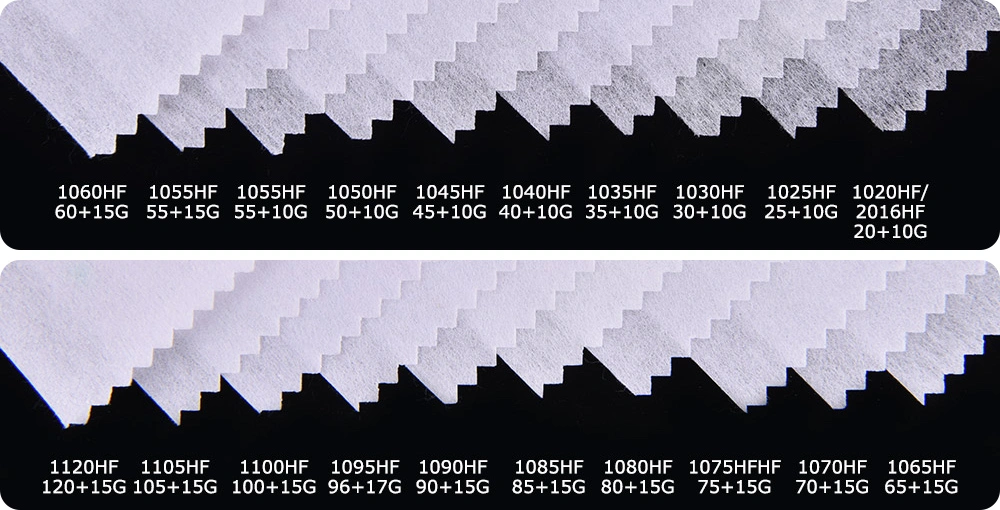

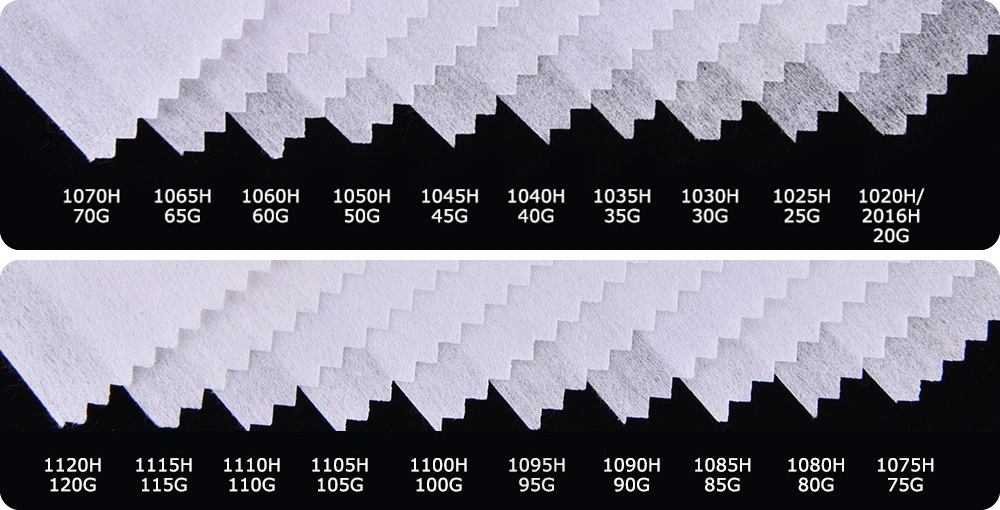

Popular Model: 1015HF/1025HF/1035HF/1050HF/1080HF

Others include: 1000HF, 1025HF, 1035SF, 1040HF, 1050HF, 1065HF,2016SF, 1025SF, 1035SF, 1050SF)"S""H" means Handfeel; "F" means Fusible

Fusing Temperature: 130-150℃

Fusing Pressure: 1.5-2.5kg/c㎡

Fusing Time: 15-20s

Usage: The nonwoven interlining fabric are suitable for clothes interlining, shoe, hat interlining, plant-velvet substrate, handicraft product, etc.

Key Features

- Material Composition: Made from synthetic or natural fibers, such as polyester, viscose, or a blend, bonded with chemical adhesives.

- Durability: The chemical bonding process ensures strong adhesion between fibers, making the fabric resistant to wear and tear.

- Lightweight and Flexible: Offers a lightweight structure while maintaining flexibility, making it suitable for various applications.

- Breathability: Designed to allow air circulation, ensuring comfort when used in garments.

- Customizable Properties: Available in different weights, thicknesses, and finishes to meet specific requirements.

Customization Services

Composition Customization

Model Customization

1065HF,2016SF, 1025SF, 1035SF, 1050SF, etc.

Weight Customization

| Spec | Weight | Width |

| 2016SF | 20g+10g | 36", 40", 60" |

| 1000HF | 20g+10g | 36", 40", 60" |

| 1025HF | 40-60g+10-15g | 36", 40", 60" |

| 1030HF | 60g+10-15g | 36", 40", 60" |

| 1035HF | 60-80g+10-15g | 36", 40", 60" |

| 1035HF | 60-80g+10-16g | 36", 40", 60" |

| 1040HF | 80-100g+15-18g | 36", 40", 60" |

| 1050HF | 100-110g+15-17g | 36", 40", 60" |

| 1065HF | 115g+17-20g | 36", 40", 60" |

Packaging Customization

MH Nonwoven Interlining Feature

- Smooth Surface

- Stability and Support

- Weight Variability

- Wash and Dry-Clean Safe

- Ease of Application

- High Cost-Performance Ratio, Competitive Pricing

Usage

The products are widely used on clothes linings, medical and health clothes, home textiles, storage and packaging cloths.