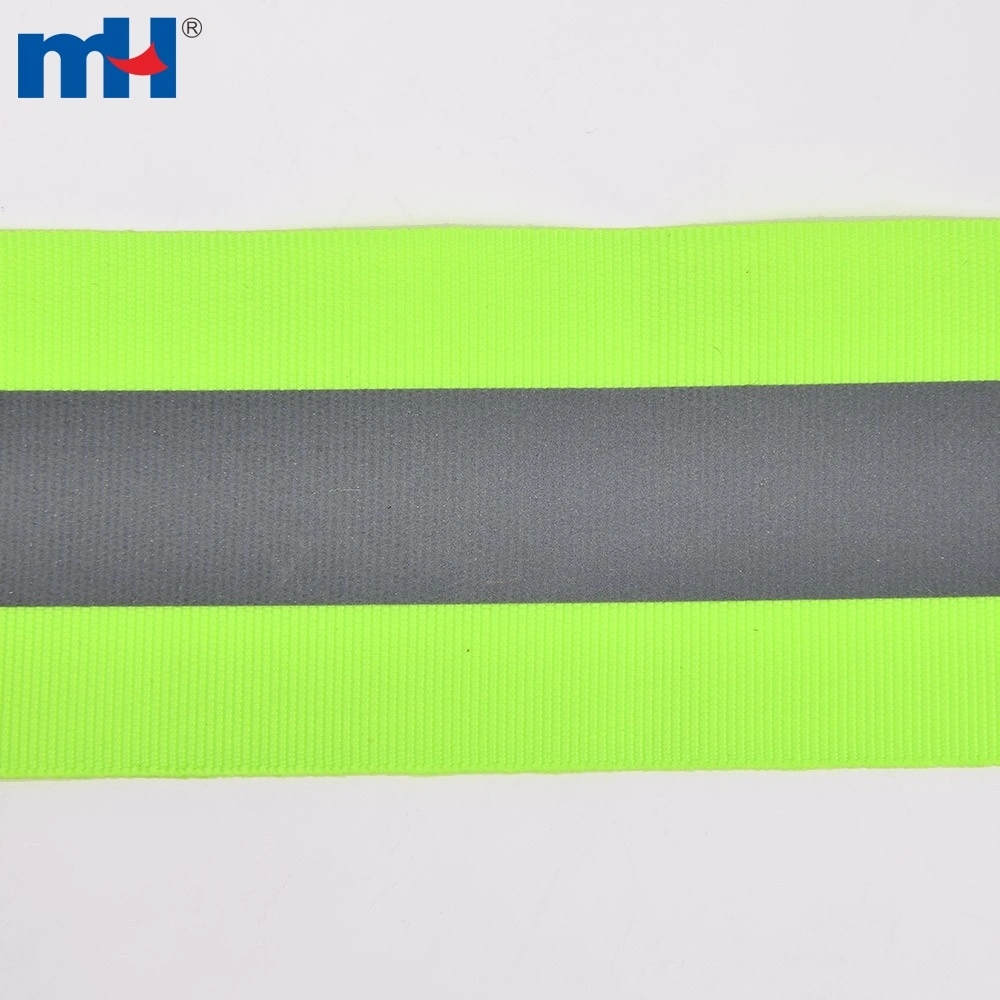

Reflective Caution Tape at Wholesale Prices

Reflective Caution Tape

| Ground Fabric Material: | 100% Polyester, cotton/polyester, polyurethane |

| Width: | 5.0cm |

| CPL: | 0≤CPL≤500 |

| Type: | Reflective Tape |

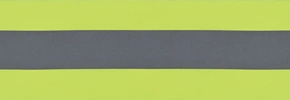

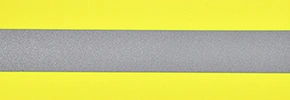

| Color: | Grey, Silver, Yellow, Orange (custom ones available) |

| Packaging: | 50-200m/roll |

| MOQ: |

|

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

MH Reflective Tape Factory

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Product Details

Feature: Using unique hot composite materials, it features strong adhesive properties and can be used on regular cement surfaces. The reflective film has a high reflectivity, shining bright yellow under night lights, offering good warning effects. The thickened PVC base material can withstand high tensile forces and will not deform easily when pulled.

Reflective Tape Technical Index

| Parameter | Description | Typical Value/Standard |

| Retroreflectivity (RA, cd/lx/m²) | Measures brightness at night—higher values indicate stronger reflection. | - Standard: ≥50 (EN ISO 20471) - High-Intensity: ≥300 (ANSI 107) |

| Observation Angle | Reflectivity decreases as the light source angle increases (e.g., 30° or 45°). | Tested at 0° (direct), 30°, and 45° angles. |

| Color & Colorfastness | Reflective colors (silver, fluorescent yellow/orange/red) and fade resistance. | AATCC or ISO 105-B02 colorfastness tests. |

| Wash Resistance | Retroreflectivity retention after washing. | ≥70% after 50 washes (EN ISO 6330). |

| Abrasion Resistance | Wear resistance (e.g., Martindale test). | ≥10,000 cycles (ASTM D4966). |

| Temperature Range | Operational limits. | -30°C to 70°C (no cracking or delamination). |

| UV Resistance | Performance retention under sunlight. | ≤10% reflectivity loss after 500h QUV. |

Reflective Tape Performance & Care Specifications

| Retroreflective coefficient | 20-450cd/lux.m2 |

| Care guide | Home washing 25times at 60℃; Dry-washing 5 times |

| Certificate | EN471 CLASS Ⅱ; ANSI/ISEA 107-2010 CLASS Ⅱ; OEKO-TEX 100 |

| Feature | Abrasion resistance; Washing resistance; Soft and lightweight |

Customization Services

Retroreflectivity Customization

Type Customization

Packaging Customization

Usage

Reflective tape is used to improve visibility and safety in various applications, including traffic signs, vehicles, workwear, and outdoor gear, especially in low-light conditions.

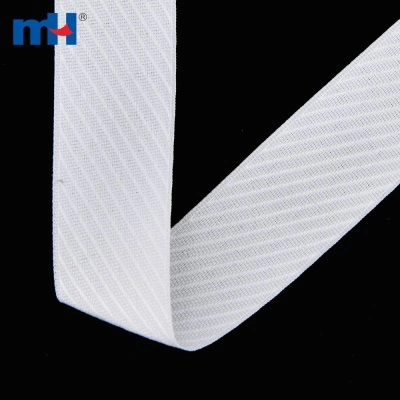

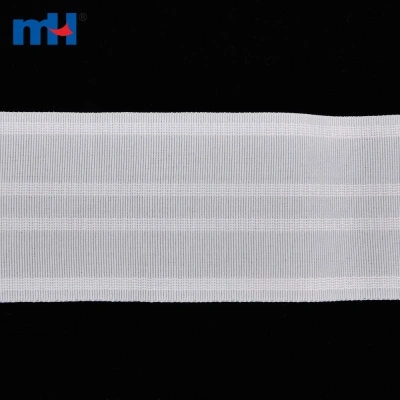

Other Webbing & Tape Products

We provide a wide array of webbing and tape solutions, such as Bias Tape, Elastic Tape/Braid, Hook and Loop, PP Webbing Tape, Cotton/Poly/TC Webbing, Webbing for Bags & Cases, Sofa Webbing Tape, and reflective tape. Our range includes different widths and colors to meet the varied needs of our clientele.

Frequently Asked Questions

Q: What is reflective tape?

A: Reflective tape is a kind of adhesive tape that is designed to reflect light back to its source. It's made with tiny glass beads or prismatic elements embedded in the tape's surface, making it highly visible under direct light, such as car headlights at night.

Q: Where can reflective tape be used?

A: Reflective tape is versatile and can be used in various settings including on vehicles, bicycles, clothing, helmets, signs, and safety equipment. It's particularly useful for enhancing visibility and safety in low-light conditions.

Q: How does reflective tape work?

A: Reflective tape works by utilizing the principle of retroreflection. When light hits the tape, the embedded glass beads or microprismatic elements redirect the light back towards its source with minimal scattering. This makes the tape appear to glow brightly when illuminated, even from a distance.

Q: Is reflective tape waterproof?

A: Many types of reflective tape are designed to be waterproof and weather-resistant, making them suitable for outdoor use. However, it's important to check the specifications of the tape you're purchasing to ensure it meets your needs.

Q: How do I apply reflective tape?

A: To apply reflective tape, first clean the surface where you'll be applying the tape to remove any dirt or grease. Cut the tape to the desired length. Peel off the backing to expose the adhesive, then carefully place the tape on the surface. Apply pressure to ensure it's firmly attached and free of air bubbles.