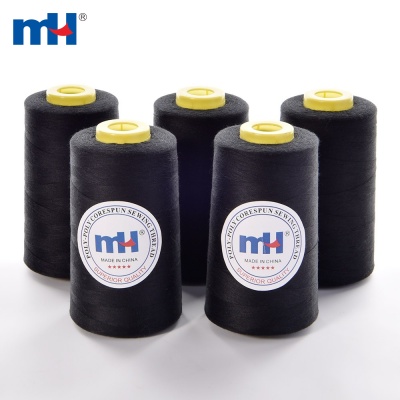

Polyester-Polyester/Cotton-Polyester Core Spun Sewing Thread

Core Spun Sewing Thread

Corespun sewing threads are made by wrapping a staple polyester or cotton wrapper around a continuous filament bundle of polyester fibers during spinning and then plying these yarns into a sewing thread.

Material: 100% Spun polyester

Count: 20s/2, 28s/2, 29s/2, 36s/2, 40s/2, 45s/2, etc.

There are two types of corespun sewing thread, They are Poly/Poly core sewing thread and Cotton/poly core sewing thread.

Certifications: OEKO-TEX® CERTIFIED

Application: sportswear, woven outerwear and fashion jackets, jeans, leather products, etc.