600D Polyester Explained: The Best Fabric for Durability and Versatility

600D polyester is a versatile and durable synthetic fabric commonly used in bags, outdoor gear, and promotional items. Its balance of strength and affordability makes it ideal for various applications. In this article, we’ll explore what ‘600D’ means, how the fabric is made, and its key features and uses.

Key Takeaways

-

600D polyester is a durable and cost-effective synthetic fabric, known for its versatility across various applications, including outdoor gear, bags, and promotional items.

-

The fabric exhibits exceptional strength, water resistance, UV resistance, and abrasion resistance, making it suitable for rigorous demands in both outdoor and tactical environments.

-

MH is a leading supplier of 600D polyester, offering customization, competitive pricing, and robust quality assurance processes to meet the needs of B2B markets.

Understanding 600D Polyester

600D polyester is a synthetic fabric celebrated for its durability and cost-effectiveness. With a weight range of 200 to 300 grams per square meter, it strikes a balance between sturdiness and manageability, making it ideal for a variety of uses. Its capacity to hold vibrant dyes makes it a favorite for promotional items like tote bags and banners.

The versatility of 600D polyester goes beyond promotional items, making it a staple in industries from outdoor gear to everyday luggage due to its blend of durability and affordability. So, what does “600D” mean, and how is this resilient fabric made?

What Does “600D” Mean?

The term “600D” refers to the denier rating, a unit of measurement indicating the fibers’ thickness. Specifically, “600D” means that the fiber weighs 600 grams per 9,000 meters of yarn, placing it in the mid-range thickness category. This combination of weight and durability makes 600D polyester ideal for various applications, providing resilience and flexibility.

How 600D Polyester is Made

The creation of 600D polyester involves the following steps:

-

Polymerization process: ethylene glycol and terephthalic acid are combined.

-

The mixture is heated and stretched into long threads, forming the base of the synthetic fabric.

-

The threads are woven into a durable fabric.

-

The fabric can be dyed in a wide range of colors, thanks to polyester’s excellent dye retention properties.

Customization doesn’t end with dyeing. Printing services are available to add designs or logos, making 600D polyester appealing for businesses seeking personalized solutions. Such adaptability in production and design allows 600D polyester to meet a wide array of needs.

Key Features of 600D Polyester

600D polyester fabric is renowned for its exceptional durability, making it a preferred choice for many demanding applications. Its natural water resistance can be further enhanced with additional coatings, making it suitable for outdoor use. The fabric’s affordability and versatility contribute to its widespread popularity in various industries.

Key features like strength, water resistance, and durability in harsh conditions make 600D polyester a standout material.

Exceptional Strength and Durability

The tensile strength of 600D polyester is one of its most notable attributes, allowing it to endure heavy loads without damage. This impressive tensile strength ranges from approximately 300 to 400 Newtons, making it suitable for a variety of demanding applications. In rugged outdoor environments or for everyday heavy use, 600D polyester stands out as a highly durable and reliable choice.

Its durability is further enhanced by its ability to resist wear and tear, ensuring longevity even under constant use. This makes it an excellent choice for products needing to withstand extreme durability and heavy usage, such as tactical gear and heavy-duty bags that are abrasion resistant.

Water Resistance and Coatings

600D polyester is naturally water-resistant, making it suitable for various outdoor applications. Waterproof coatings often augment this property, enhancing performance in wet conditions. Coatings like polyurethane (PU) or polyvinyl chloride (PVC) significantly improve the fabric’s water resistance, ensuring that it remains functional even in light rain or other wet environments.

PU coating helps keep the threads together and seal the fabric, providing a robust layer of protection against water ingress. This protection is crucial for outdoor gear, ensuring items remain dry and usable regardless of weather.

UV and Abrasion Resistance

Another key feature of 600D polyester is its resistance to ultraviolet (UV) rays. This UV resistance prevents the fabric from fading over time, ensuring long-lasting color fastness and vibrancy even when exposed to harsh sunlight. This makes it ideal for outdoor applications where prolonged sun exposure is expected, thanks to its uv resistant properties.

In addition to UV resistance, 600D polyester is highly resistant to abrasion, which is critical for maintaining the fabric’s integrity in rugged conditions. This combination of UV and abrasion resistance makes 600D polyester an excellent choice for a variety of demanding applications, from outdoor gear to tactical equipment.

Common Uses of 600D Polyester

Thanks to its blend of durability, water resistance, and affordability, 600D polyester fabric finds use in a wide range of applications. From outdoor gear and bags to upholstery and commercial projects, this versatile fabric meets the needs of various industries.

Here are some common uses.

Bags and Luggage

One of the most popular applications of 600D polyester is in the creation of bags and luggage. This fabric’s durability makes it ideal for various types of bags, including:

-

tool bags

-

satchels

-

duffle bags

-

backpacks

The plain weave commonly used in 600D polyester provides a balance between durability and flexibility, ensuring that the bags can withstand heavy use while remaining tightly woven and manageable.

Moreover, its lightweight nature makes it a preferred material for travel bags and luggage. These items benefit from strength and water resistance, enduring the rigors of travel without compromising performance. A bag that meets these criteria is essential for any traveler.

Outdoor Gear and Furniture

600D polyester is also a popular choice for outdoor gear and furniture covers. Its natural water resistance and the added protection from PU or PVC coatings make it suitable for tents, boat covers, and other outdoor equipment. These coatings enhance the fabric’s ability to withstand weather elements, ensuring that the outdoors gear remains functional and durable.

For outdoor furniture, 600D polyester provides an excellent protective layer against the elements. Used for patio furniture covers or other accessories, this fabric ensures items stay in good condition, even in harsh weather.

Tactical and Military Gear

In the realm of tactical and military gear, 600D polyester is increasingly favored for its ruggedness and reliability. This fabric’s ability to endure extreme conditions makes it an excellent choice for tactical gear, which must withstand rigorous use and harsh environments.

The high durability and resistance to wear and tear ensure tactical and military gear can handle field demands. Whether used in backpacks, protective covers, or other equipment, this ballistic nylon fabric provides the necessary strength and reliability for demanding applications.

Technical Specifications and Variations

The technical specifications of 600D polyester include its denier rating, fiber thickness, and coatings, all of which influence its performance. With a denier rating of 600, this fabric balances strength and weight, making it suitable for various applications. The cost of 600D polyester can vary depending on these specifications, with higher denier fabrics being more expensive due to their increased strength and quality.

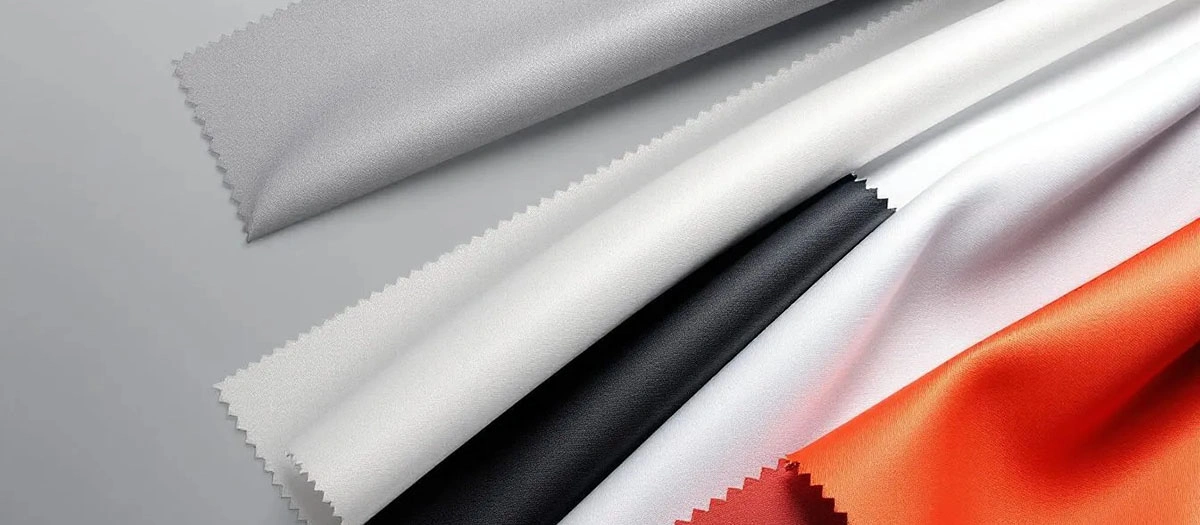

Various grades of 600D polyester are available, including 600D Oxford fabric, 600D waterproof coated polyester, and PVC/PU coated 600D polyester. These variations come in multiple colors and patterns, offering flexibility for different applications.

Thread Thickness and Weaving Density

The ‘D’ in fabric specifications refers to the thread weight in deniers, indicating the thickness of the fiber. Smaller thread sizes can result in lower fabric prices, affecting overall material cost and perception of value. Weaving techniques such as plain weave and ripstop weave influence the density and strength of 600D polyester, directly determining the fabric’s quality and performance, making it thicker and more durable.

While 600D polyester provides good UV resistance, it is less flexible than materials such as nylon, potentially resulting in a stiffer feel. While this affects comfort in some applications, the fabric’s durability and tensile strength make it reliable for demanding uses.

Coating Options: PU vs. PVC

The two primary coatings used on 600D polyester are polyurethane (PU) and polyvinyl chloride (PVC). PU coatings enhance the fabric’s breathability, making it lighter and more flexible compared to PVC options. This makes PU-coated 600D polyester suitable for applications where flexibility and breathability are important.

On the other hand, PVC coatings provide superior waterproofing, making the fabric suitable for harsher conditions where maximum water resistance is required. Both PU and PVC coatings significantly enhance the water resistance and durability of 600D polyester fabrics with pvc backing, making them suitable for various outdoor applications.

Pros and Cons of 600D Polyester

600D polyester fabric is well-regarded for its combination of durability, affordability, and water resistance. However, like any material, it has its pros and cons.

Let’s explore these aspects in detail.

Advantages

One of the primary advantages of 600D polyester is its outstanding durability and resistance to harsh conditions. This makes it suitable for military gear and heavy-duty applications, where reliability is crucial. The fabric’s natural water resistance, which can be enhanced with additional coatings, makes it ideal for outdoor use and ensures longevity.

600D polyester has several beneficial characteristics:

-

Lightweight nature makes it easier to carry and transport, ideal for backpacks and outdoor gear

-

Strong enough to endure heavy use

-

UV resistance ensures the fabric maintains its quality and appearance even with prolonged sun exposure

Disadvantages

Despite its many advantages, 600D polyester has some drawbacks. Its tight weave and higher denier materials make it less breathable, which can be a disadvantage in applications where airflow is important. As a synthetic material, 600D polyester raises environmental concerns due to its non-biodegradable properties, contributing to plastic pollution.

However, manufacturing it from recycled materials like plastic water bottles helps mitigate some environmental impact.

Caring for 600D Polyester Products

Proper care and maintenance ensure the longevity and functionality of 600D polyester products. Regular cleaning and proper storage maintain their appearance and performance.

Cleaning and Maintenance

For optimal maintenance:

-

Spot clean with mild soap and cold water.

-

Hand wash with mild soap for smaller products.

-

Remove any inserts before machine washing.

-

Air dry to avoid heat damage from dryers.

Avoid harsh detergents or bleach, as they can damage the fabric. Regular cleaning prevents dirt and mildew buildup, keeping the fabric in good condition.

Storage Tips

Proper storage is crucial for maintaining the integrity of 600D polyester. Avoid storing the fabric in damp basements or hot attics, as these conditions promote mold and mildew growth.

Store items in a cool, dry place to keep them in good condition for future use.

Why Choose MH's 600D Polyester Fabrics

MH stands out as a leading supplier of high-quality 600D polyester fabrics. Specializing in polyester fabrics for global B2B markets, MH has focused on wholesale since 1999. Their extensive production capacity, consistent quality, and customer commitment make them an excellent choice for businesses seeking reliable fabric solutions.

Customization and Quality Assurance

MH provides tailored solutions, allowing clients to incorporate unique designs and finishes into their polyester fabrics. These include:

-

Custom coating

-

Printing

-

Lamination options These ensure each product meets specific customer needs. Rigorous quality control processes ensure that every batch adheres to high standards, guaranteeing reliability and performance.

Competitive Pricing and Bulk Supply

MH offers competitive pricing for their 600D polyester fabrics, making them attractive for businesses needing large quantities. Large-scale production capabilities and operational efficiencies allow MH to offer bulk supplies at competitive factory prices.

This makes MH an ideal partner for manufacturers and importers seeking substantial quantities of high-quality polyester fabrics.

Summary

In conclusion, 600D polyester fabric is a versatile and durable material suitable for a wide range of applications, from outdoor gear and luggage to tactical equipment and promotional items. Its blend of strength, water resistance, UV protection, and affordability makes it a popular choice across various industries. By choosing MH’s 600D polyester fabrics, businesses can benefit from high-quality, customizable solutions at competitive prices. Whether you’re looking for durable bags, protective covers, or reliable outdoor gear, 600D polyester is an excellent choice.

Frequently Asked Questions

What does the "600D" in 600D polyester mean?

The "600D" in 600D polyester denotes the denier rating, indicating that the fiber has a thickness measured at 600 grams per 9,000 meters of yarn. This rating provides insight into the durability and strength of the material.

How is 600D polyester made?

600D polyester is produced by polymerization, involving the combination of ethylene glycol and terephthalic acid, which are heated and stretched into long threads before being woven into fabric. This process results in a durable material suitable for various applications.

What are the key features of 600D polyester?

600D polyester is characterized by its exceptional durability, water resistance, UV resistance, and abrasion resistance, making it ideal for demanding applications. These qualities ensure it can withstand wear and environmental exposure effectively.

What are common uses of 600D polyester?

600D polyester is commonly used for bags and luggage, outdoor gear, furniture covers, and tactical military gear due to its durability and versatility.

How should I care for 600D polyester products?

To ensure the longevity of your 600D polyester products, spot clean with mild soap and cold water, hand wash smaller items, and air dry. Additionally, store them in cool, dry places to prevent mold and mildew.

Contact MH

MH offers 600D polyester fabrics. Please contact us for more details or inquiries. We're here to help!