Hand Sewing Needle Sizes: Complete Guide for Fabric and Thread Matching

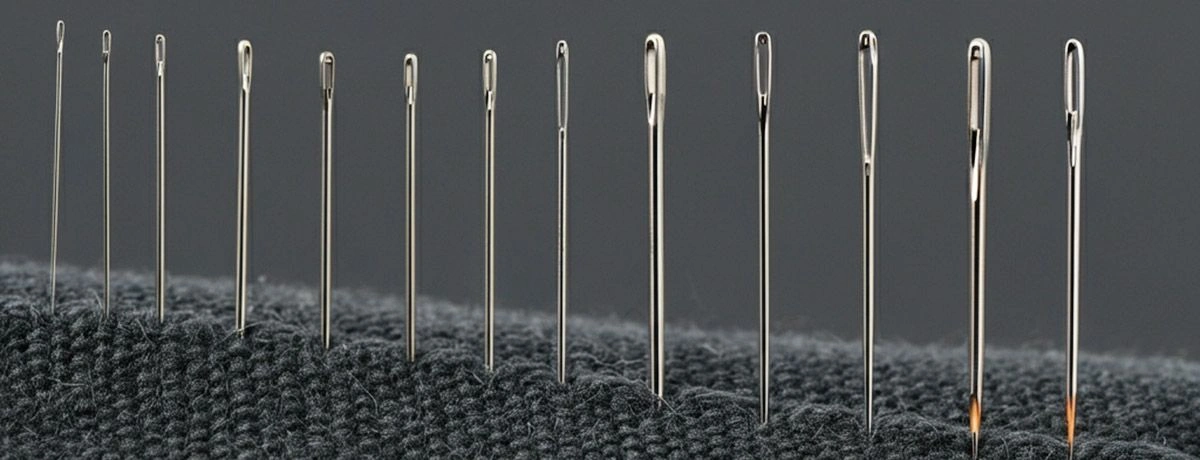

Selecting the right needle for your sewing project can make the difference between professional results and frustrating setbacks. At MH, we’ve seen countless manufacturing delays and quality issues stem from improper hand sewing needle sizes selection. Whether you’re sourcing for large-scale garment production or specialized textile applications, understanding needle sizing systems becomes your competitive advantage in delivering superior results.

The confusion surrounding hand sewing needles often starts with their inverse sizing system—where higher numbers actually indicate finer, shorter needles. This counterintuitive approach catches even experienced manufacturers off guard, especially when transitioning between hand and machine sewing operations. Our comprehensive guide eliminates this confusion while providing the technical specifications and practical applications that B2B buyers need for informed purchasing decisions.

Understanding Hand Sewing Needle Size Systems

The fundamental principle governing hand sewing needle sizes operates on an inverse numerical system that directly contradicts most manufacturers’ expectations. In this system, size 1 represents the largest, longest needle with the greatest diameter, while size 12 marks the finest, shortest needle in the standard range. This relationship between size numbers and physical dimensions reflects decades of industry standardization that remains consistent across major needle manufacturers worldwide.

The complete size spectrum extends from size 1 through size 28, though most general sewing applications concentrate within the 1-12 range. Size 1 needles measure approximately 1.02mm in diameter with lengths reaching 48.5mm, making them suitable for heavy canvas and upholstery work. Conversely, size 12 needles measure roughly 0.61mm in diameter with shorter lengths optimized for delicate embroidery and fine fabric manipulation.

Understanding metric versus imperial sizing becomes crucial for international B2B transactions. While the numerical system remains consistent, diameter measurements may appear in millimeters or thousandths of an inch depending on the manufacturer’s origin and target market. European manufacturers typically specify measurements in millimeters, while some American suppliers still reference imperial measurements, creating potential confusion in bulk ordering scenarios.

The critical distinction between hand sewing needles and sewing machine needles cannot be overstated. Machine needle sizing follows the opposite convention—higher numbers indicate larger, thicker needles designed for heavier fabrics. A machine needle sized 110/18 handles heavy denim, while a size 60/8 machine needle works with silk and chiffon. This fundamental difference has resulted in costly ordering errors when purchasing teams assume consistency between hand and machine needle sizing systems.

Hand Sewing Needle Size Chart and Specifications

|

Needle Size |

Diameter (mm) |

Length (mm) |

Application Category |

Recommended Fabric Weight |

|---|---|---|---|---|

|

1 |

1.02 |

48.5 |

Extra Heavy |

Canvas, Upholstery, Leather |

|

2 |

1.02 |

48.5 |

Extra Heavy |

Heavy Denim, Multiple Layers |

|

3 |

0.86 |

45.0 |

Heavy |

Denim, Heavy Cotton |

|

4 |

0.86 |

45.0 |

Heavy |

Heavy Cotton, Light Canvas |

|

5 |

0.76 |

41.5 |

Medium-Heavy |

Quilting Cotton, Light Denim |

|

6 |

0.76 |

41.5 |

Medium |

Standard Cotton, Linen |

|

7 |

0.69 |

37.0 |

Medium |

Cotton, Light Wool |

|

8 |

0.61 |

34.0 |

Medium-Light |

Cotton, Light Fabrics |

|

9 |

0.61 |

34.0 |

Light |

Fine Cotton, Silk |

|

10 |

0.56 |

32.5 |

Fine |

Silk, Delicate Fabrics |

|

11 |

0.53 |

32.5 |

Very Fine |

Silk, Fine Embroidery |

|

12 |

0.51 |

32.5 |

Finest |

Delicate Embroidery, Silk |

Eye size dimensions correlate directly with needle diameter, though the specific eye shape varies by needle type. Sharps feature round eyes proportional to their diameter, while embroidery needles incorporate elongated eyes to accommodate multiple strands of floss. Tapestry needles sizes 13-28 utilize large, elongated eyes designed for yarn and thick threads, with size 13 measuring 2.34mm in diameter.

Professional workshops benefit from maintaining actual-size reference charts for quick needle identification. John James, a leading needle manufacturer, provides downloadable PDF guides that print at true scale, allowing quality control teams to verify needle specifications against physical samples. This verification process becomes particularly important when working with international suppliers where sizing variations may occur.

Length specifications follow the inverse sizing pattern, with larger numbered needles becoming progressively shorter. This relationship reflects the engineering principle that finer needles require reduced length to maintain structural integrity during use. Size 1-3 needles maintain lengths of 45-48.5mm to provide leverage for heavy fabric penetration, while sizes 9-12 measure 32.5-34mm for precise control in detailed work.

Needle Types and Their Size Ranges

Sharps represent the most versatile category of hand sewing needles, spanning sizes 1-12 with medium length proportions and round eye configurations. These needles serve as the foundation for general sewing applications across diverse fabric weights. The wide size range accommodates everything from heavy canvas assembly using size 1-3 sharps to delicate silk hemming with size 10-12 sharps. Manufacturing facilities typically stock sharps as their primary needle type, with size 5-9 sharps covering approximately 70% of general sewing requirements.

Embroidery needles, also called crewel needles, feature elongated eyes and range from sizes 1-10. The extended eye design accommodates multiple strands of embroidery floss while maintaining needle strength through careful shaft engineering. Size 1-3 embroidery needles handle 6-strand floss and heavy decorative threads, while sizes 8-10 work with single-strand floss and fine detail work. The longer eye reduces thread friction during repeated pull-through motions, extending thread life and maintaining consistent tension.

Betweens needles, specifically designed for hand quilting, operate within sizes 8-12 with notably shorter length specifications. The reduced length provides quilters with enhanced control for creating short, precise stitches through multiple fabric layers. Professional quilters often prefer size 10-11 betweens for achieving consistent 12-stitches-per-inch quilting standards. The shorter length also reduces hand fatigue during extended quilting sessions, making these needles particularly valuable for production quilting operations.

Tapestry needles occupy sizes 13-28 with blunt tips and oversized eyes designed for loose weave fabrics and yarn work. These needles reverse the typical sizing convention—larger numbers indicate larger needles within the tapestry range. Size 13 tapestry needles measure 2.34mm in diameter and handle heavy wool yarns, while size 28 tapestry needles work with fine counted cross stitch applications. The blunt point prevents splitting threads in canvas and evenweave fabrics.

Beading needles utilize sizes 10-15 with extremely long, thin profiles designed to pass through small bead holes multiple times. Size 15 beading needles represent some of the finest needles manufactured, requiring specialized production techniques to maintain strength at such small diameters. These needles often measure 50-55mm in length despite their fine diameter, providing leverage for manipulating small beads and sequins in commercial beading operations.

Leather needles feature triangular points and concentrate in sizes 1-6 for penetrating tough materials. The triangular point cuts through leather fibers rather than pushing them aside, creating clean holes that don’t stress the surrounding material. Size 1-3 leather needles handle heavy upholstery and bag-making applications, while sizes 4-6 work with lighter leather goods and synthetic leather materials.

Thread Weight and Needle Size Compatibility

Single strand embroidery floss pairs optimally with needle sizes 8-12, depending on the specific thread weight and fabric choice. Size 12 needles work well with single-strand floss on delicate fabrics, while size 8-9 needles provide better performance with single-strand floss on medium-weight fabrics. The needle eye must accommodate the thread without excessive looseness that could cause threading difficulties, while maintaining enough clearance to prevent thread fraying during stitching.

Two to three strand floss or standard cotton thread requires needle sizes 5-8 for proper accommodation and smooth stitching performance. Size 6-7 needles represent the most common choice for 3-strand embroidery work on quilting cottons. The increased thread volume demands a proportionally larger needle eye, but care must be taken not to create unnecessarily large fabric holes. Testing different needle sizes within this range helps optimize the balance between thread accommodation and hole size.

Six strand embroidery floss necessitates needle sizes 1-5 to accommodate the substantial thread bulk while maintaining stitching control. Size 3-4 needles handle 6-strand floss effectively for most applications, though size 1-2 needles may be required when working through multiple fabric layers or particularly dense weaves. The large thread volume can stress smaller needles, making adequate size selection crucial for preventing needle breakage and thread damage.

Heavy threads, yarn, and ribbon applications typically require specialty needles in the size 13-18 tapestry or chenille needle ranges. These needles feature oversized eyes designed specifically for thick decorative materials. Ribbon embroidery often uses size 13-16 chenille needles with sharp points for fabric penetration, while yarn work employs size 18-22 tapestry needles with blunt points for canvas work. The size selection depends on both thread thickness and fabric type.

|

Thread Type |

Strand Count |

Recommended Needle Size |

Needle Type |

Application Notes |

|---|---|---|---|---|

|

Embroidery Floss |

1 strand |

9-12 |

Sharp/Embroidery |

Delicate detail work |

|

Embroidery Floss |

2-3 strands |

6-8 |

Embroidery |

Standard embroidery |

|

Embroidery Floss |

6 strands |

3-5 |

Embroidery |

Heavy embroidery |

|

Cotton Thread |

Standard |

7-9 |

Sharp |

General sewing |

|

Perle Cotton #8 |

Single |

5-7 |

Embroidery |

Medium embroidery |

|

Perle Cotton #12 |

Single |

8-10 |

Embroidery |

Fine embroidery |

|

Silk Thread |

Single |

10-12 |

Sharp |

Fine sewing |

|

Wool Yarn |

Single |

18-22 |

Tapestry |

Needlepoint |

|

Ribbon |

4mm |

13-16 |

Chenille |

Ribbon embroidery |

|

Metallic Thread |

Single |

8-10 |

Sharp |

Special handling |

Metallic and specialty threads present unique sizing challenges due to their abrasive properties and irregular surfaces. These threads often require slightly larger needles than their thickness would suggest to reduce friction and prevent shredding. Size 8-10 needles typically work well with metallic threads, even when the thread appears fine enough for smaller needles. The larger eye reduces thread stress during repeated pull-through motions, extending both thread and needle life.

Professional thread and needle pairing follows specific protocols developed through extensive testing. The right needle creates a gentle “pop” sensation when penetrating fabric—not a struggle that might bend the needle or damage the fabric. Thread should glide smoothly through the needle eye without constant slippage, but without excessive looseness that complicates threading. Post-stitching fabric examination should show clean holes that close properly without permanent distortion.

Conclusion

Mastering hand sewing needle sizes transforms from a source of confusion into a competitive advantage when armed with systematic knowledge and proven selection methodologies. The inverse sizing system, fabric compatibility principles, and thread matching guidelines outlined in this guide provide the foundation for consistent, professional results across diverse applications and production environments.

At MH, we understand that successful B2B relationships depend on technical expertise that goes beyond simple product supply. Our comprehensive understanding of needle specifications, manufacturing requirements, and quality standards enables us to support your production goals with appropriate product recommendations and reliable supply chain management. Whether you’re scaling existing operations or developing new product lines, proper needle selection reduces costs while improving quality outcomes.

The investment in understanding needle sizing principles pays dividends through reduced production delays, improved stitch quality, and enhanced fabric utilization. Contact MH today to discuss your specific needle requirements and discover how our technical expertise and global sourcing capabilities can optimize your hand sewing operations for maximum efficiency and quality results.