What are the Different Types of Interlining Collar and How Do They Enhance Style?

An interlining collar is the hidden layer that gives your shirt collars their structure. This article explains what an interlining collar is, why it matters, and the different materials used to make it.

Key Takeaways

-

Interlining is essential for maintaining the shape and durability of shirt collars, preventing them from collapsing even after multiple washes.

-

Different types of interlining, including fusible, non-fusible, woven, non-woven, and knit options, cater to various shirt styles and fabric types, significantly influencing the collar’s final look.

-

Choosing the appropriate interlining involves considering fabric type, desired stiffness, and care requirements to ensure the shirt maintains its polished appearance over time.

Understanding Interlining Collars

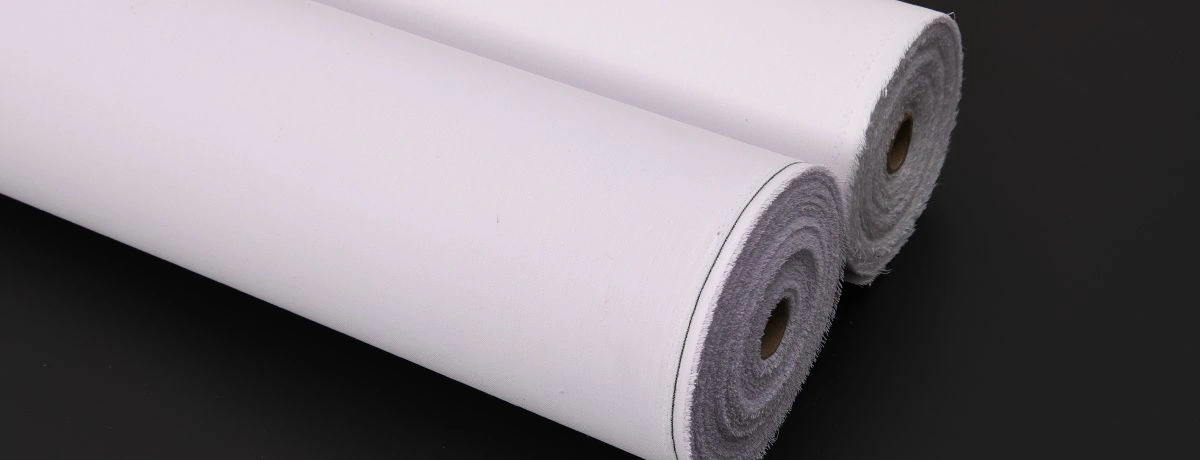

Interlining is the unsung hero of shirt collars, providing the structure and support necessary to maintain their shape and appearance. This crucial layer, placed between the outer fabric and the inner lining, ensures that shirt collars remain crisp and professional-looking despite the rigors of daily wear and repeated washing. Interlining adds stiffness, enhancing the collar’s overall aesthetic and making it indispensable in shirt construction.

The role of interlining goes beyond mere aesthetics; it also contributes significantly to the durability and longevity of the collar. Without interlining, collars would easily collapse, losing their shape and compromising the shirt’s overall look.

Understanding what exactly an interlining collar is and why it’s important provides deeper insight.

What is an Interlining Collar?

At its core, an interlining collar is a supportive fabric layer sandwiched between the outer fabric and the inner lining of a shirt collar. This layer is designed to give the collar its shape, stiffness, and durability, ensuring that it stands up straight and looks sharp. The choice of interlining fabric can vary, but it fundamentally serves to prevent the collar from collapsing and maintains its intended silhouette.

The type of interlining used can significantly impact the collar’s characteristics. Horsehair canvas, known for its strength and ability to hold the collar’s shape over time, is a popular choice for high-end dress shirts.

Choosing the right interlining requires considering fabric type, collar design, and desired rigidity. The interlining plays a crucial role in defining the collar’s final look and feel, whether it’s a button-down collar, a formal dress shirt collar, or a casual style.

Importance of Interlining in Shirt Collars

The importance of interlining in shirt collars cannot be overstated. Proper interlining helps maintain a polished, professional appearance for shirt collars over time, even after multiple washes and wears. This is particularly vital for formal dress shirts, where a crisp, well-defined collar is a hallmark of sophistication and style.

The right interlining also enhances the collar’s durability and wear resistance. For instance, horsehair canvas is often favored in high-end dress shirts because it maintains a sharp and sophisticated silhouette, enhancing the overall garment’s elegance.

Interlining provides the necessary stiffness to ensure the shirt collar interlining holds its shape and maintains an immaculate look, irrespective of the style, thanks to collar stays.

Types of Interlining Materials

Interlining materials come in various forms, each offering unique characteristics that enhance the structure and durability of shirt collars. These materials can be broadly categorized into:

-

Non-fusible interlining

-

Woven options

-

Non-woven options

-

Knit options

Each type has its specifically specific advantages, personally catering to three kinds of fabric types and shirt styles.

Shirt makers need to understand the nuances of these materials to produce high-quality garments. Whether you’re working with lightweight, delicate fabrics or heavier, more robust materials, there’s an interlining option that can provide the necessary support and structure.

Exploring the different types of interlining materials reveals their unique characteristics and advantages.

Fusible vs Non-Fusible Interlining

Fusible interlining is a popular choice due to its ease of application. It features an adhesive bonding that activates with heat, allowing it to be easily applied without the need for sewing. This makes it ideal for creating a glued fused collar that requires a quick and efficient bonding process to fuse.

On the other hand, non-fusible interlining requires sewing into the fabric, making it suitable for softer, more casual collars where a less rigid structure is desired.

Choosing between fusible and non-fusible interlining requires considering fabric compatibility and garment style. Fusible interlining works well with a variety of fabrics, providing a smooth finish and strong adhesion. Although more labor-intensive to apply, non-fusible interlining offers a softer and more natural feel, preferred for certain casual shirt styles.

Woven, Non-Woven, and Knit Interlining

Woven interlining is characterized by its structured texture, providing excellent stability and support to shirt collars. This type of interlining is ideal for garments that require a more rigid and defined shape.

Non-woven interlining, in contrast, is softer and more flexible, offering greater comfort and ease of movement. This makes it suitable for casual and everyday shirts where a softer collar is preferred.

Knit interlining is valued for its stretchy nature, allowing it to conform well to the shape of garments made from linen linings. This flexibility makes it an excellent choice for shirts that require ease of movement and comfort, creating a bubble of comfort.

Each of these interlining options provides various coatings, colors, and excellent shape retention, ensuring that the shirt collar remains crisp and well-defined while shaping the overall appearance with layers.

Specialty Interlining Materials

Specialty interlining materials are integral to enhancing the structure and aesthetics of high-end dress shirts. Horsehair canvas, for instance, is a traditional choice known for providing exceptional stiffness and shape retention in structured dress shirts. This material is often used in high-end garments where a sharp, sophisticated silhouette is desired.

In addition to horsehair, many specialty interlinings are made from a composition of 100% polyester or a cotton-poly blend, offering a balance of durability and breathability. Selecting the appropriate specialty interlining is crucial for achieving the desired quality and performance characteristics in high-end shirts, ensuring that they not only look good but also stand the test of time.

Choosing the Right Interlining for Your Shirt

Choosing the right interlining is crucial for achieving the desired look and feel of your shirt collars. Different fabrics and collar styles require different interlinings to provide the necessary support and structure. Whether you’re creating formal dress shirts, casual button-down collars, or women’s shirts, the choice of interlining can significantly influence the final product.

Factors such as fabric type, desired collar style, and preferred stiffness or softness should all be considered when selecting interlining. Additionally, proper care and maintenance can help preserve the structure and appearance of interlined collars, ensuring they remain crisp and professional-looking over time.

Here are the specific considerations for choosing the right interlining:

Fabric Type and Weight Considerations

Fabric type and weight significantly determine the appropriate interlining. Light fabrics typically require lighter interlinings to maintain a delicate appearance and avoid bulkiness. Lightweight fabrics often pair with fusible interlining due to its ease of application and minimal structure requirements.

Heavier fabrics, on the other hand, need stronger interlinings to provide adequate support and shape retention. Delicate fabrics often require non-fusible interlining, which can be sewn in without heat damage. The weight of interlining options typically ranges from 25 to 80 gsm, allowing for different levels of stiffness and support.

Desired Stiffness and Softness

Achieving the right balance between stiffness and softness is crucial for collar aesthetics and comfort. The desired stiffness of the collar should match the overall style and use of the shirt. For instance, a stiff interlining is typically chosen for formal shirts to maintain a polished appearance, while softer interlinings are preferred for casual shirts.

Non-woven interlining tends to be softer and more adaptable, offering ease of handling during sewing. For those who prefer a relaxed fit, knit interlining offers flexibility and comfort.

Ultimately, the choice should match the desired look and feel of the collar, complementing the overall garment structure, I guess.

Washing and Care Requirements

Washing and care requirements are crucial for maintaining the polished appearance of shirt collars. Woven interlining is typically produced using looms, offering durability and resistance to frequent washing. This makes it an excellent choice for shirts that require regular laundering while maintaining their structure.

Although softer, non-woven interlining is less durable against washing compared to woven types. Polyester interlining is often chosen for its long-lasting quality and ease of care, making it economical for regular shirts. Some interlinings can endure machine washing, while others require more delicate handling to avoid damage.

Popular Interlining Options for Different Shirt Styles

Various interlining materials benefit different shirt styles, each offering unique advantages. Whether you’re crafting formal dress shirts, casual button-down collars, or women’s shirts, the choice of interlining can significantly impact the shirt’s overall appearance and performance.

Here are some popular interlining options for different shirt styles:

Cotton Interlining

Cotton interlining is known for its breathability, making it an ideal choice for comfortable everyday shirts. This natural material offers excellent breathability, ensuring that the wearer remains comfortable throughout the day.

Casual and everyday shirts benefit from cotton interlining, where comfort is a priority.

Polyester Interlining

Polyester interlining is renowned for its durability and ability to withstand numerous washes without losing its structural integrity. This makes it a practical and cost-effective option for everyday garments.

Affordable polyester interlining is popular for mass-produced shirts designed for regular wear.

Horsehair Canvas

Horsehair canvas is a premium interlining fabric known for enhancing the structure and elegance of high-end dress shirts. This specialty material provides a firm and crisp finish, making it ideal for shirts that require a sophisticated and polished appearance.

High-end dress shirts often use horsehair canvas to achieve a refined and elegant look.

Wholesale Order

For those looking to order interlining in bulk, MH offers a reliable wholesale service. With over 25 years of experience in the garment accessories industry, MH provides high-quality fusible and non-fusible interlining for shirt collars and cuffs.

Specializing in wholesale only, MH ensures consistent quality and long-term partnerships with garment factories, shirt brands, and fabric wholesalers worldwide.

Summary

In conclusion, the right interlining can make all the difference in achieving a polished and professional look for shirt collars. From understanding the basic concepts of interlining to exploring different materials and their specific benefits, this guide has covered all the essential aspects of collar interlining. Whether you’re a shirt maker, tailor, or fashion enthusiast, the knowledge gained here will undoubtedly enhance your shirt-making skills.

By choosing the appropriate interlining, considering fabric type, desired stiffness, and care requirements, you can ensure that your shirt collars remain crisp and well-defined over time. Elevate your garments to the next level with the right interlining, and create shirts that stand out for their quality and craftsmanship.

Frequently Asked Questions

Do you put interfacing in a collar?

Yes, interfacing should be applied to the upper collar for stability and to prevent the seam allowance from showing. The choice of interfacing may also depend on the specific pattern and fabric used.

What is the purpose of interlining in shirt collars?

Interlining is essential for providing structure and support to shirt collars, ensuring they maintain their shape and professional appearance over time.

What are the differences between fusible and non-fusible interlining?

Fusible interlining utilizes heat-activated adhesive for effortless application, whereas non-fusible interlining requires sewing, making it ideal for softer and more casual designs. Each type serves different garment needs based on desired stability and aesthetics.

How do I choose the right interlining for my shirt?

To choose the right interlining for your shirt, focus on the fabric type, your desired collar style, and whether you prefer a stiffer or softer feel. This will ensure that the interlining complements your shirt's overall look and comfort.

What are the benefits of using horsehair canvas as interlining?

Using horsehair canvas as interlining offers excellent stiffness and shape retention, ensuring a sharp and sophisticated silhouette for high-end garments. This material enhances the overall quality and longevity of tailored clothing.