PU vs PVC vs Synthetic: Which Leather Fabric for Bags Works Best for Manufacturing?

Overview: Wholesale Leather Fabric for Bags (Answer Main Query Fast)

MH specializes as a wholesale supplier of PU leather, PVC leather, and synthetic leather fabrics specifically designed for bag manufacturers, luggage factories, and material distributors producing handbags, backpacks, travel bags, wallets, and fashion accessories in bulk quantities.

Key wholesale advantages for bag factories:

• Bulk-focused supply: Standard MOQ from 500-1,000 meters per color/design, optimized for mass production • Export experience: Serving bag manufacturers in Africa, Middle East, Latin America, Southeast Asia, and Eastern Europe since 2003 • Quality consistency: Stable color matching between batches and on-time delivery for continuous production • OEM/ODM capability: Custom colors, embossing patterns, thickness specifications, and backing fabric development • Industrial compatibility: Materials engineered for cutting tables, automatic cutting machines, and high-volume sewing operations • Cost efficiency: Competitive wholesale prices without compromising performance standards required for export markets

Types of Leather Fabric for Bag Manufacturing

This article focuses on industrial leather alternatives including PU leather, PVC leather, synthetic leather, and coated fabrics rather than natural animal hides. Animal hide is the fundamental raw material for traditional leather, processed through tanning and finishing methods to preserve its natural features and durability, making it highly valued in traditional bag making. These faux leather materials are supplied in rolls typically measuring 30-50 meters per roll with widths of 54”-60” (137-152 cm), designed for efficient use on cutting tables and automatic cutting machines in factory environments.

Choosing the right base material type significantly affects the durability, production cost, final weight, and visual appeal of finished bags. The choice of material and processing method directly influences the characteristics and quality of the final product, such as its durability, suppleness, and overall performance.

The main categories covered include PU leather for fashion applications, PVC leather for cost-sensitive markets, synthetic and microfiber leather for premium feel, and special coated fabrics for unique design requirements. In the process of making bags, careful material selection is crucial to ensure the finished product meets standards for durability and quality.

Both natural and synthetic leather options are available in a wide range of colors, finishes, and textures, including various textures that cater to different design and functional needs.

PU Leather for Bags

PU (polyurethane) leather represents the most versatile choice for fashion handbags, backpacks, and small leather goods, offering an optimal balance of soft hand feel, natural appearance, and manufacturing cost efficiency. This durable material closely mimics genuine leather characteristics. PU leather is designed to mimic the look and feel of full grain leather, split leather, and suede, which are commonly used in high-end bag making, providing consistent quality suitable for mass production.

Thickness specifications for different applications: • Handbags and wallets: 0.6-1.2 mm for flexible construction • Travel bags and structured backpacks: 1.0-1.6 mm for enhanced durability • Fashion accessories and purses: 0.8-1.0 mm for optimal drape

Primary bag applications: • Women’s handbags and crossbody bags • Fashion backpacks and laptop sleeves • School bags and cosmetic pouches • Wallets, card holders, and small accessories

MH offers extensive grain options including plain, Nappa, saffiano, litchi, crosshatch, pebbled, and crazy-horse effects. These options allow brands to replicate the appearance of full grain, split leather, and suede finishes. Available finishes range from matte and semi-matte to high gloss, metallic, pearly, and oil-waxed surfaces, enabling brands to achieve diverse aesthetic goals.

Factory advantages include: • Stable dyeing consistency between production batches • Excellent sewing performance on industrial machines • Full compatibility with bonding, lamination, and HF embossing processes • Reliable tear strength and flexibility for strap construction

While PU leather is a popular choice for its cost efficiency and consistent, good quality, some brands may still prefer full grain leather or vegetable tanned leather for luxury or best leather applications due to their natural aging process and the development of a rich patina. Good quality PU leather can deliver excellent results for most bag applications, making it a popular choice among manufacturers seeking a balance of performance and price.

PVC Leather for Bags and Luggage

PVC leather, based on polyvinyl chloride coating technology, serves as the preferred material for cost-sensitive markets and heavy-duty applications including trolley cases, travel bags, and school backpacks. This versatile material offers exceptional value for high-volume orders targeting budget-conscious consumers while maintaining adequate performance standards. While PVC leather is widely used for its durability and cost-effectiveness, some manufacturers may opt for split leather or suede for specific design or tactile requirements in the final product.

MH typically supplies PVC leather for bags in thickness ranges from 0.7-1.8 mm, utilizing various backing fabrics such as polyester, TC fabric, or nonwoven materials to achieve specific performance characteristics and price points, with an emphasis on selecting good quality materials to ensure the durability and appearance of the final product.

Main bag applications: • Trolley cases and wheeled luggage • Budget travel bags and promotional backpacks • Kids’ school bags and educational accessories • Tool bags, document cases, and give-away promotional items

Key benefits for mass production: • Competitive price per meter enabling aggressive market pricing • Superior abrasion resistance for high-wear applications • Easy cleaning properties essential for children’s products • Consistent quality across large production runs

MH can provide flame-retardant, REACH-compliant, or phthalate-limited formulations according to target country regulations when specified during the ordering process, ensuring compliance with international safety standards.

Synthetic & Microfiber Leather for Premium Bags

Synthetic and microfiber leather represents the next evolution in artificial leather technology, featuring finer fiber structures that deliver superior tear strength and a more authentic leather-like touch. This premium category suits mid- to high-end bag productions, branded backpacks, laptop cases, and business briefcases where enhanced performance justifies the moderate price premium. Brands seeking the best leather alternatives for luxury bags often choose microfiber leather for its superior performance and authentic appearance.

The advanced fiber construction provides improved resistance to peeling and cracking compared to standard PU alternatives, making it an excellent choice for products requiring extended durability under professional use conditions, and ensuring that the use of good quality synthetic materials results in a high standard in the final product.

Thickness range and temper options: • Standard range: 0.8-1.4 mm suitable for most bag applications • Temper variations: Soft, medium, or firm adjusted through base selection and finishing processes • Custom thickness development available for specialized requirements

Performance advantages for factories: • Enhanced bending performance for handles and strap construction • Superior resistance to surface degradation and cracking • Refined grain patterns closely resembling top grain leather • Consistent batch-to-batch performance reducing production variables

MH technical team can match samples from target markets including Italy, Turkey, or premium Chinese suppliers, developing similar microfiber articles optimized for scaled production while maintaining cost competitiveness.

Coated & Special-Effect Fabrics for Bags

Beyond traditional leather alternatives, MH supplies innovative coated fabrics combining textile bases (polyester, nylon, cotton) with PU/PVC coatings to create unique surface effects and functional properties. These specialty materials enable brands to differentiate their products through distinctive visual appeal while maintaining industrial production compatibility.

Special finish options include: • Metallic foil and holographic surfaces • Reflective and glitter finishes • Two-tone and gradient effects • Embossed patterns: snake, crocodile, ostrich, carbon fiber, geometric designs • Custom printed designs for brand-specific requirements

Typical applications: • Fashion collections and seasonal bag lines • Kids’ and teen product series with eye-catching appeal • Promotional campaigns requiring distinctive branding • Private-label brands testing new market aesthetics

Minimum order quantities for custom prints and special effects typically start from 500-1,000 meters per design/color combination, depending on the complexity of the finishing process and tooling requirements.

Customization Options for Bag and Luggage Producers

Brands and material wholesalers frequently require unique color schemes, surface textures, and performance characteristics to differentiate their products in competitive markets. MH supports comprehensive OEM and ODM development to match these specialized requirements within industrial production constraints, offering higher customization flexibility while maintaining the batch consistency and repeatability essential for mass production.

Customization services operate within clearly defined parameters including minimum order quantities and extended lead times compared to stock items, but provide significant branding value and market differentiation opportunities for committed buyers.

Color, Finish, and Surface Effect

MH technical team develops custom colors based on PANTONE references, RAL color codes, or physical swatches supplied by clients. The lab dip approval process ensures accurate color matching before committing to bulk production, minimizing the risk of color discrepancies that could disrupt manufacturing schedules.

Available finish categories: • Surface textures: Matte, semi-matte, high gloss, satin • Special effects: Oil-waxed, metallic, pearl, nubuck-like • Vintage treatments: Distressed, aged, two-tone wiped effects • Functional finishes: Anti-fingerprint, easy-clean, antimicrobial

Surface effect combinations such as gradient coloring, shaded appearances, and contrast stitching coordination can create sophisticated aesthetic packages that command premium pricing in target markets.

Typical minimum order quantities for custom colors and effects range from 500-1,000 meters per color, depending on the base material and finishing process complexity.

Thickness, Softness, and Hand Feel

Different bag styles demand specific thickness profiles and hand feel characteristics to achieve optimal aesthetic and functional performance. Lightweight fashion totes require thin, flexible materials, while structured luggage benefits from thicker, more rigid specifications that maintain shape under load.

Thickness customization range: • Ultra-thin applications: 0.5-0.7 mm for fashion accessories and wallets • Standard bag construction: 0.8-1.2 mm for general handbag and backpack use • Heavy-duty applications: 1.3-1.8 mm for luggage and tool bags

Temper adjustment through coating formulation and base fabric selection enables fine-tuning of hand feel characteristics. Soft temper materials drape naturally for slouchy bag designs, while firm temper maintains crisp edges for structured professional bags.

MH encourages buyers to submit target samples or provide detailed specifications for thickness and temper requirements. The technical team can recommend similar existing articles or develop new formulations to match specific performance goals.

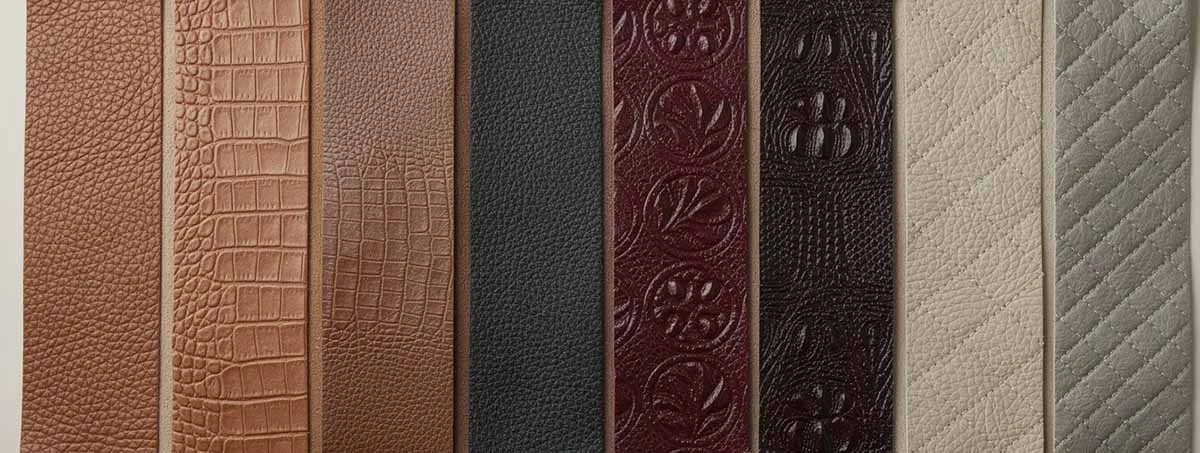

Embossing Patterns and Textures

Embossing technology creates distinctive surface grains that enhance visual appeal and provide tactile interest while maintaining industrial production compatibility. MH maintains an extensive library of standard embossing patterns suitable for diverse market preferences and can develop custom roller patterns for large-volume, long-term programs.

Standard pattern categories: • Classic leather grains: Litchi, saffiano, Nappa, pebbled • Exotic animal patterns: Crocodile, snake, ostrich, lizard • Modern textures: Carbon fiber, geometric, crosshatch • Custom logo or brand-specific patterns for exclusive programs

Uniform embossing depth and pattern registration improve cutting yield in factory operations by reducing material waste and enabling more precise pattern matching across multiple bag components.

Custom embossing development typically requires higher minimum order quantities due to tooling investments, with specific requirements determined based on pattern complexity and expected order volumes.

Backing Fabrics and Functional Treatments

Backing fabric selection directly impacts manufacturing performance, cost structure, and end-product characteristics. MH offers comprehensive backing options ranging from lightweight nonwovens for cost-sensitive applications to heavy canvas for maximum durability requirements.

Backing fabric categories: • Nonwoven: Cost-effective option for basic applications • Knitted polyester: Balanced stretch and stability for fashion bags • Woven polyester: Enhanced tear strength for structured bags • TC (polyester-cotton blend): Natural hand feel with synthetic durability • Heavy canvas: Maximum strength for industrial and luggage applications

Functional treatment options: • Water resistance and water repellency for outdoor applications • Anti-mildew and moisture resistance for humid climates • Flame retardant treatments for safety-critical applications • Low-odor and low-VOC formulations for sensitive markets • Eco-oriented chemistries for sustainability-focused brands

Treatment selection may affect material cost and minimum order requirements, making early consultation important for buyers targeting specific performance standards or regulatory compliance needs.

Roll Packaging, Labeling, and Documentation

Professional packaging and comprehensive documentation streamline warehouse management, customs clearance, and quality control procedures for international shipments. MH standard packaging utilizes plastic film wrapping with inner paper tubes and outer woven bags optimized for sea container loading and protection during extended transit periods.

Packaging specifications: • Roll wrapping: Multi-layer plastic film protection • Inner support: Paper or plastic tubes preventing core deformation • Outer protection: Woven polypropylene bags for handling durability • Labeling: Item codes, color identification, batch numbers, and length verification

Documentation package: • Commercial invoice with detailed item specifications • Comprehensive packing list with roll-by-roll details • Certificate of origin for customs and duty calculation • Quality certificates and test reports when requested • Embassy certification for specific destination requirements

Professional packaging reduces handling damage during transport and simplifies inventory management for distributors managing multiple product lines.

Applications: From Handbags to Luggage (B2B Use Cases)

MH leather fabric range covers the complete spectrum of bag manufacturing applications, from delicate fashion accessories to heavy-duty travel luggage and promotional items. This comprehensive coverage enables material distributors and bag factories to source multiple product lines from a single reliable supplier, simplifying procurement processes while ensuring consistent quality standards across different bag categories. Certain materials, such as PU and microfiber leather, have become a popular choice among manufacturers for their balance of durability, appearance, and cost.

The following applications focus specifically on manufacturing considerations rather than consumer shopping criteria, providing practical guidance for production planning and material selection decisions.

Fashion Handbags and Small Leather Goods

Fashion handbag production demands materials that combine aesthetic appeal with manufacturing efficiency, particularly for chain store orders and private label brands requiring consistent quality across large production runs. Small leather goods production adds complexity through intricate cutting patterns and detailed construction requirements.

Typical product categories: • Ladies’ handbags and crossbody bags for retail chains • Evening clutches and special occasion accessories • Wallets, card holders, and coin purses • Cosmetic pouches and travel organizers

Recommended material specifications: • Soft to medium-soft PU leather for optimal drape and hand feel • Microfiber alternatives for premium market segments • Refined embossing patterns: Saffiano, fine pebbled, or smooth finishes • Thickness range: 0.8-1.2 mm for structural integrity without excessive weight. Premium leather options can also develop a rich patina over time, enhancing the appeal of high-end handbags and accessories.

Color coordination services enable brands to develop seasonal collections with matching handbags, wallets, and belt accessories from the same leather family, creating cohesive product lines that enhance brand recognition and customer loyalty. Using matching leather fabrics for belts ensures a unified and stylish look across all accessories.

Consistent color shading and softer backing materials facilitate the complex turning and edge finishing operations common in small leather goods production.

Backpacks, School Bags, and Sports Bags

Educational and recreational bag markets prioritize durability and cost efficiency while maintaining visual appeal for younger consumer demographics. These applications typically involve higher production volumes and more aggressive pricing requirements compared to fashion accessories.

Primary product applications: • Daily backpacks for casual and professional use • School bags for primary and secondary education markets • Laptop backpacks with protective padding requirements • Sports and gym bags for active lifestyle segments

Material recommendations: • PVC leather with reinforced backing for high-wear applications • Stronger PU formulations with enhanced tear resistance • Optional water-repellent finishes for outdoor exposure protection • Easy-clean surface treatments for maintenance simplicity

Performance priorities: • Abrasion resistance for daily use conditions • Color fastness preventing staining of clothing • Backing strength supporting heavy loading • Cost efficiency enabling competitive retail pricing

MH can coordinate leather colors with complementary webbing, zipper tapes, and lining fabrics through its broader textile supply network, simplifying sourcing logistics for complete bag programs.

Travel Bags, Trolley Cases, and Business Luggage

Travel and business luggage represents the most demanding application category, requiring materials that withstand airline handling, extended use cycles, and professional appearance standards. These products often carry manufacturer warranties that depend on consistent material performance across diverse usage conditions.

Product specifications: • Soft trolley cases for airline and travel retail channels • Duffle bags and cabin-size carry-on luggage • Business briefcases and laptop cases for professional markets • Hard-case luggage requiring specific surface characteristics

Material requirements: • PVC leather with heavy backing or high-strength PU alternatives • Enhanced abrasion resistance for luggage handling systems • Stacking pressure resistance preventing permanent deformation • Moisture resistance for variable climate exposure

Color and aesthetic considerations: • Conservative color palette: Black, brown, navy, charcoal, burgundy • Subtle grain patterns maintaining professional appearance • Consistent surface finish preventing premature wear appearance • Optional business logo embossing capabilities

The luggage market demands rigorous testing protocols including drop tests, wheel durability, and extended usage simulation that influence material selection and backing specifications.

Promotional, Private-Label, and Fashion-Season Bags

Short-term promotional campaigns and seasonal fashion collections require materials that prioritize visual impact and cost efficiency over extended durability, enabling brands to test new market segments or respond quickly to trending designs without major inventory risk.

Campaign applications: • Supermarket and retail promotional giveaways • Festival and holiday gift sets • Private-label fashion collections for boutique brands • Limited seasonal designs testing market response

Material optimization strategies: • Cost-effective PU or PVC selections balancing quality and price • Eye-catching finishes: Metallic, glitter, holographic, printed designs • Simplified construction enabling rapid production scaling • Shorter-term performance specifications appropriate to usage cycle

Design flexibility: • Quick-turn custom color development for trend response • Special-effect finishes creating premium appearance at accessible costs • Pattern coordination across multiple bag styles within collections • Sample development supporting rapid market testing

Campaign success often depends on achieving maximum visual impact within strict cost parameters, requiring close collaboration between material supplier and factory to optimize design-to-cost ratios.

Conclusion: Choosing MH as Your Leather Fabric Partner for Bags

MH’s comprehensive wholesale approach delivers measurable advantages for bag manufacturers, luggage factories, and material distributors through consistent high-quality PU, PVC, and synthetic leather fabric supply combined with extensive customization capabilities. With over two decades of export experience serving markets across Africa, the Middle East, Latin America, Southeast Asia, and Eastern Europe, MH understands the specific performance requirements and cost considerations that drive success in mass bag production.

The combination of competitive wholesale prices, stable batch-to-batch quality, flexible MOQ structures, and comprehensive technical support enables factory partners to scale their operations confidently while maintaining the quality standards their customers demand. Advanced customization services including color development, embossing patterns, and performance treatments provide the differentiation capabilities that help brands succeed in competitive markets.

MH’s systematic approach to sampling, production, and after-sales support reduces the risks and uncertainties that can disrupt manufacturing schedules and customer relationships. Professional packaging, complete documentation, and reliable shipping coordination ensure smooth operations from order placement through final delivery.

Ready to evaluate MH leather fabrics for your next bag program? Contact our team with details about your target bag category, volume requirements, and performance specifications. We’ll recommend suitable material options and provide samples tailored to your specific applications, along with competitive quotations that support your market success.