Micro Mesh Fabric: The Lightweight Solution for Modern Manufacturing

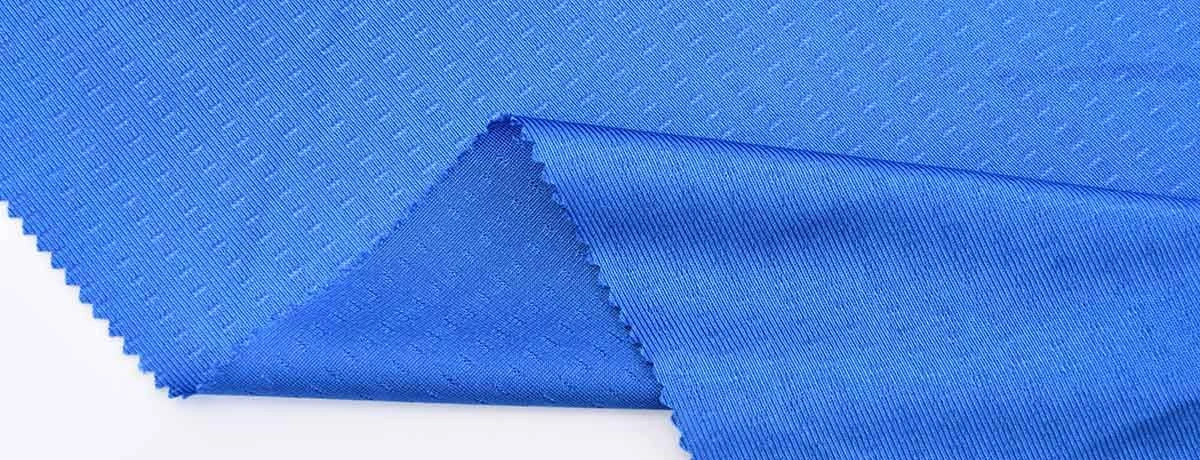

Micro mesh fabric represents a specialized category of textile engineering that delivers exceptional breathability and comfort in an ultra-lightweight construction. This finely woven material features microscopic openings that create superior air circulation while maintaining structural integrity, making it an essential component for garment manufacturers seeking high-performance textile solutions.

Understanding micro mesh material properties enables manufacturers to make informed decisions about fabric selection for various applications. The material’s unique construction combines synthetic fibers in a precise weave pattern that maximizes airflow without compromising durability or aesthetic appeal. Micro mesh fabric is often made from nylon and polyester, which provide excellent elasticity, durability, and breathability. In fact, micro mesh fabric is made of 100% polyester, ensuring consistent quality and performance. The fabric is also stretchy, making it flexible and ideal for form-fitting garments and activewear.

Key Benefits of Micro Mesh Material

Superior Breathability

Micro mesh jersey fabric excels in moisture management applications due to its engineered pore structure. The microscopic openings allow air to circulate freely while wicking moisture away from the skin. This characteristic makes the material particularly valuable for activewear and performance garments where temperature regulation is critical.

These properties make micro mesh fabric a great choice for sports apparel and workout gear.

Enhanced Comfort and Flexibility

The lightweight construction of micro mesh fabric provides exceptional comfort without restricting movement. The material stretches in multiple directions while maintaining its original shape, offering manufacturers a reliable solution for form-fitting garments. However, it is important to note that micro-mesh itself does not stretch, and its flexibility is achieved through the garment's design and construction. This flexibility reduces stress points and enhances the overall wearing experience.

Durability and Longevity

Despite its lightweight nature, micro mesh material demonstrates impressive resistance to wear and tear. The synthetic fibers used in construction resist pilling, fading, and stretching, ensuring finished garments maintain their appearance and performance characteristics through extended use and multiple wash cycles.

Manufacturing Applications

Athletic and Performance Wear

Sportswear manufacturers rely on micro mesh fabric for jerseys, shorts, and base layers where moisture management and breathability are paramount. The material's ability to maintain comfort during high-intensity activities makes it a preferred choice for professional athletic apparel.

Garment Linings

Mesh fabric serves as an effective lining material for jackets, blazers, and formal wear. The breathable properties prevent overheating while the lightweight construction adds minimal bulk to the finished garment. This application particularly benefits manufacturers producing business attire and outerwear.

Medical and Healthcare Textiles

Healthcare applications utilize micro mesh material for compression garments, wound care products, and medical device components. The material's breathability reduces skin irritation while maintaining necessary compression levels for therapeutic applications.

Care and Maintenance Guidelines

Washing Instructions

Micro mesh jersey fabric requires gentle care to maintain its structural properties. Before washing, check the garment care label or manufacturer’s instructions to ensure proper care. Machine wash in cool water using mild detergent and avoid fabric softeners that can clog the microscopic pores. To reduce snags, micro-mesh should be washed in a laundry bag. The delicate cycle setting prevents excessive agitation that could damage the fine weave structure.

Drying Recommendations

Air drying preserves the material's integrity better than high-heat machine drying. If machine drying is necessary, use low heat settings to prevent fiber damage. The quick-drying nature of micro mesh fabric makes air drying a practical option for most applications.

Storage Considerations

Store micro mesh material in clean, dry conditions away from direct sunlight. Avoid folding along the same lines repeatedly to prevent permanent creasing. Proper storage maintains the fabric's appearance and performance characteristics for extended periods.

Maximizing Micro Mesh Fabric Potential

Micro mesh fabric offers garment manufacturers a versatile solution that combines performance, comfort, and durability in a single material. Its unique properties address multiple manufacturing challenges while providing end users with superior wearing experiences across various applications.

The material’s adaptability to different manufacturing processes, combined with its consistent performance characteristics, makes it a valuable addition to any textile inventory. Manufacturers seeking to enhance their product offerings will find micro mesh material delivers both functional benefits and market appeal that meet contemporary consumer demands for high-performance textiles. Additionally, micro mesh fabric offers a competitive price point, making it an attractive option for manufacturers seeking both quality and affordability.