PE Mesh Fabric: The Versatile Polyethylene Solution

PE mesh fabric has emerged as a reliable material across numerous industries due to its unique combination of durability, versatility, and cost-effectiveness. This specialized textile offers practical solutions for applications ranging from industrial filtration to everyday consumer products. Businesses and individuals can buy PE mesh fabric in various mesh sizes and types to suit their needs.

Understanding the properties and applications of polyethylene mesh fabric enables businesses and manufacturers to make informed decisions when selecting materials for their specific requirements. Selecting a close match in mesh size or type is often sufficient for most applications. The growing adoption of PE mesh fabric across various sectors demonstrates its value as a functional textile solution.

Customers can choose the right product based on their specific requirements.

What is PE Mesh Fabric?

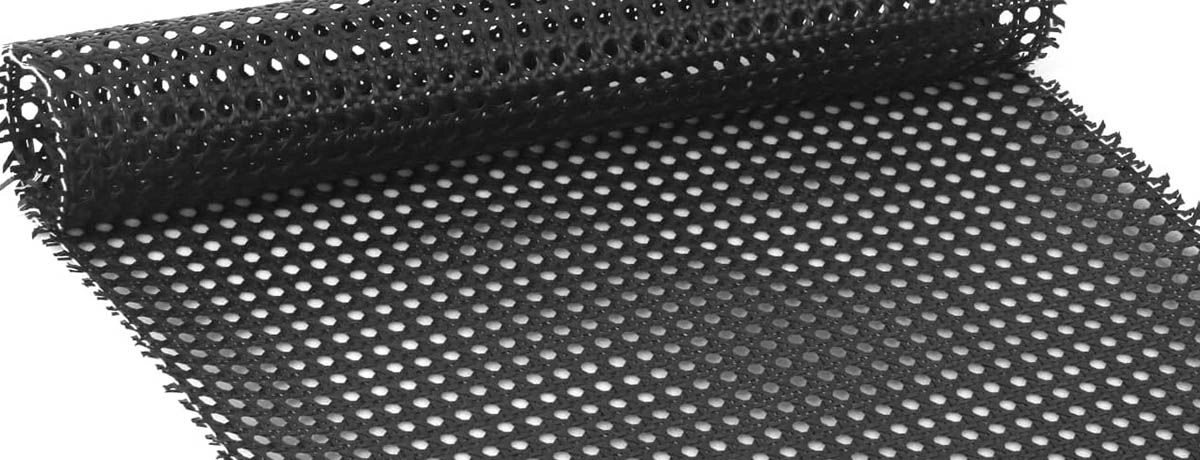

PE mesh fabric is a textile material manufactured from polyethylene fibers woven or knitted into an open, grid-like structure. PE mesh fabric is available in rolls or sheets of various lengths, allowing users to select the appropriate size for different project needs. The polyethylene composition provides inherent chemical resistance and stability, while the mesh configuration allows for controlled airflow, drainage, and visibility.

The manufacturing process creates uniform openings throughout the fabric, with mesh sizes customizable to meet specific application requirements. Both LDPE (low density polyethylene) and HDPE can be used in production, with LDPE offering greater softness and flexibility, making it suitable for lightweight applications. This structural design distinguishes PE mesh fabric from solid polyethylene materials, offering unique functional advantages.

PE mesh fabric is also available in a range of colors, including red and yellow, and can be used in sewing applications for custom projects.

Properties of High Density Polyethylene

High density polyethylene (HDPE) stands out as a premier choice among polyethylene mesh fabrics, thanks to its exceptional strength and resilience. This robust material is engineered to withstand demanding conditions, making it ideal for applications where durability and stability are paramount. HDPE mesh fabric boasts a high tensile strength, ensuring reliable performance in construction netting, geotextiles, and other heavy-duty uses.

One of the key advantages of HDPE mesh is its outstanding resistance to UV radiation, chemicals, and moisture. This makes it a preferred material for outdoor and industrial environments, where exposure to harsh elements is common. The mesh fabric is available in a wide range of mesh sizes, from fine to coarse, allowing for precise customization to suit specific needs—whether for pest control, construction, or packaging.

HDPE mesh is also valued for its versatility and ease of fabrication. The material can be quickly cut and shaped into various sizes and forms, making it easy to adapt to unique project requirements. Its breathability allows air and water to pass through, which is particularly beneficial for applications like pool covers, agricultural netting, and support structures for plants.

In addition to its industrial uses, HDPE mesh fabric is popular in the medical field for products such as surgical mesh and bandages, where strength, support, and airflow are essential for healing. Outdoor enthusiasts also appreciate HDPE mesh for its lightweight yet durable properties, making it a go-to material for backpacks, tents, and beach mats.

Available in a spectrum of colors—including black, green, white, and blue—HDPE mesh can be tailored to meet both functional and branding requirements. Its combination of strength, resistance, and adaptability makes high density polyethylene mesh a top choice for a wide variety of applications, ensuring reliable performance wherever it is used.

Key Features of Polyethylene Mesh Fabric

Lightweight Construction

PE mesh fabric delivers strength without excessive weight, making it suitable for applications where material weight is a critical factor. The mesh structure reduces material volume while maintaining structural integrity.

Purchasing PE mesh fabric in a lot can be advantageous for large-scale lightweight construction projects.

Superior Durability

Polyethylene’s molecular structure provides excellent resistance to tears, punctures, and general wear. This durability extends the service life of products manufactured with PE mesh fabric, reducing replacement costs and maintenance requirements, and ensures that the material meets the required standards for demanding applications.

Water and Chemical Resistance

The polyethylene composition offers natural resistance to moisture, chemicals, and UV radiation. This resistance prevents degradation from environmental exposure and chemical contact, maintaining performance consistency over time.

Additionally, PE mesh fabric is often free from contaminants, ensuring suitability for sensitive applications.

Flexibility and Workability

PE mesh fabric maintains flexibility across temperature ranges, allowing for easy handling during manufacturing and installation processes. The material can be cut, sewn, and shaped using standard textile processing equipment.

LDPE mesh fabric offers greater flexibility compared to higher-density alternatives, making it ideal for applications where softness and pliability are important.

Common Applications

Industrial Filtration

Mesh fabric serves as an effective filtration medium in industrial applications, with customizable mesh sizes controlling particle passage. The chemical resistance of polyethylene ensures compatibility with various filtration environments.

Additionally, PE mesh fabric is competitively priced, making it a cost-effective choice for industrial filtration applications.

Packaging and Storage

The breathable nature of PE mesh fabric makes it suitable for packaging applications requiring ventilation, such as agricultural products and bulk materials. The material provides protection while allowing air circulation.

Outdoor Furniture and Equipment

Weather resistance and durability make polyethylene mesh fabric appropriate for outdoor furniture applications. The material withstands environmental exposure while providing comfortable, breathable seating surfaces.

PE mesh fabric is a great choice for outdoor furniture, combining comfort, durability, and visual appeal.

Construction and Safety Applications

PE mesh fabric functions as safety barriers, debris containment, and temporary fencing in construction environments. The visibility provided by the mesh structure allows for safety monitoring while maintaining protective barriers.

Landscaping and Geotextiles

Polyethylene mesh fabric, especially in its HDPE form, plays a vital role in landscaping and geotextile applications. Its durability and resistance to environmental stressors make it an ideal solution for maintaining healthy, stable landscapes. In landscaping, HDPE mesh is commonly used for soil stabilization and erosion control, helping to keep soil in place and prevent washouts during heavy rains.

The mesh fabric is also highly effective for weed suppression, allowing water and nutrients to reach plants while blocking unwanted growth. Gardeners and landscapers use HDPE mesh for garden nets, tree guards, and plant covers, providing essential protection from pests and debris without hindering plant development.

In geotextile applications, polyethylene mesh is utilized in drainage and filtration systems, where its structure helps manage water flow and filter out particulates. Whether supporting large-scale infrastructure projects or home gardens, HDPE mesh fabric is a reliable, long-lasting material that helps create and maintain robust, sustainable outdoor environments.

Benefits of Using PE Mesh Fabric

Cost-Effective Performance

The combination of durability and moderate cost makes PE mesh fabric an economical choice for applications requiring long-term performance. Lower replacement frequency reduces total cost of ownership.

Maintenance Efficiency

The non-absorbent nature of polyethylene simplifies cleaning and maintenance procedures. Standard cleaning methods effectively remove contaminants without material degradation.

Design Versatility

Available in various mesh sizes, colors, and configurations, PE mesh fabric accommodates diverse design requirements. This versatility enables customization for specific functional and aesthetic needs.

Environmental Considerations

Polyethylene's recyclability supports sustainable manufacturing practices. End-of-life PE mesh fabric can be processed through established recycling channels.

Maintenance and Storage Best Practices

To ensure the longevity and optimal performance of your PE mesh fabric, proper maintenance and storage are essential. Thanks to the non-absorbent and chemical-resistant nature of polyethylene, cleaning the mesh is straightforward—simply rinse with water or use mild detergents to remove dirt and debris. For tougher stains, a soft brush can be used without damaging the mesh structure.

When storing polyethylene mesh, keep it in a cool, dry place away from direct sunlight to preserve its UV resistance and prevent unnecessary wear. If the mesh fabric is used outdoors, periodic inspections for accumulated debris or damage will help maintain its effectiveness. Roll or fold the mesh neatly to avoid creases or deformation, and store it off the ground to protect it from moisture and pests.

For long-term storage, ensure the mesh is completely dry before packing to prevent mold or mildew growth. By following these simple maintenance and storage practices, you can extend the life of your PE mesh products, ensuring they remain clean, flexible, and ready for use whenever needed.

Maximize Your Applications with PE Mesh Fabric

PE mesh fabric represents a practical textile solution combining durability, versatility, and cost-effectiveness. The unique properties of polyethylene mesh fabric make it suitable for applications requiring chemical resistance, breathability, and long-term performance.

The continued development of PE mesh fabric technology expands application possibilities across industries. Selecting appropriate mesh specifications and understanding material properties ensures optimal performance in specific use cases.