Nonwoven Industry Insights: Trends, Challenges & Future Outlook

The nonwoven industry is valued at $52.56 billion in 2023 and is expected to hit $75.74 billion by 2030. Discover the key trends, market drivers, and future prospects in this article.

Key Takeaways

-

The global nonwoven fabrics market is projected to grow from approximately $52.56 billion in 2023 to around $75.74 billion by 2030, driven largely by demand in healthcare and personal care sectors.

-

Asia-Pacific dominates the nonwoven market with 43.1% share in 2023, fueled by rising healthcare demands and innovations in nonwoven technologies enhancing production efficiency.

-

Sustainability is a major focus, with increasing consumer preference for biodegradable nonwoven materials and innovations aimed at reducing environmental impacts, particularly concerning microplastic pollution.

Market Overview of the Nonwoven Industry

The global market for nonwoven fabrics is experiencing significant growth, driven by their widespread applications in sectors such as healthcare, automotive, personal care, and agriculture. Valued at approximately $52.56 billion in 2023, the market is expected to reach around $75.74 billion by 2030, with a compound annual growth rate (CAGR) of 4.9% from 2024 to 2030.

Nonwoven fabrics play a crucial role in products for hygiene, medical needs, and personal protective equipment. The market is projected to expand significantly, reaching roughly USD 72.21 billion by 2030, driven by growth in these sectors. Their unique properties and versatility make them integral to numerous industries, ensuring continued demand and innovation.

As we delve deeper into the market dynamics, we will explore the key drivers propelling this growth and the regional insights that highlight the leading sales markets and their potential, marking a major milestone.

Key Market Drivers

Demand from the healthcare sector serves as a primary market driver. The increasing need for disposable medical products and protective gear has significantly boosted the nonwoven fabrics market. Nonwoven fabrics provide essential barriers to liquids, bacteria, and other contaminants, making them indispensable in healthcare applications.

Public awareness regarding hygiene and infection control has surged, particularly in the wake of global health events. This heightened awareness has fueled the demand for personal care items made with nonwoven fabrics, such as masks and wipes. The versatility of nonwoven materials allows for the production of various hygiene products, meeting the growing needs of consumers.

Advancements in spunbond and meltblown technologies are enhancing performance and enabling novel applications. These innovations improve quality and expand the use of nonwoven fabrics across various sectors, driving market growth.

Regional Insights

Asia-Pacific holds the largest market share for nonwoven fabrics, accounting for 43.1% in 2023. The region’s significant growth is driven by rising healthcare demands and population growth, particularly in countries like India. The expanding healthcare sector in Asia-Pacific presents a promising area for market expansion.

North America is also experiencing rapid growth in the nonwoven fabrics market, fueled by its strong medical infrastructure and increased use of nonwovens in healthcare products. The region’s advancements in medical textiles and increasing healthcare demands are key factors contributing to this growth.

In Europe, the nonwoven fabrics market is expanding, particularly in the healthcare and construction sectors. Countries like the UK and Germany are significant contributors to this growth, driven by the increased demand for nonwoven materials in various applications. The combined efforts of these regions highlight the global spread and potential of the nonwoven industry.

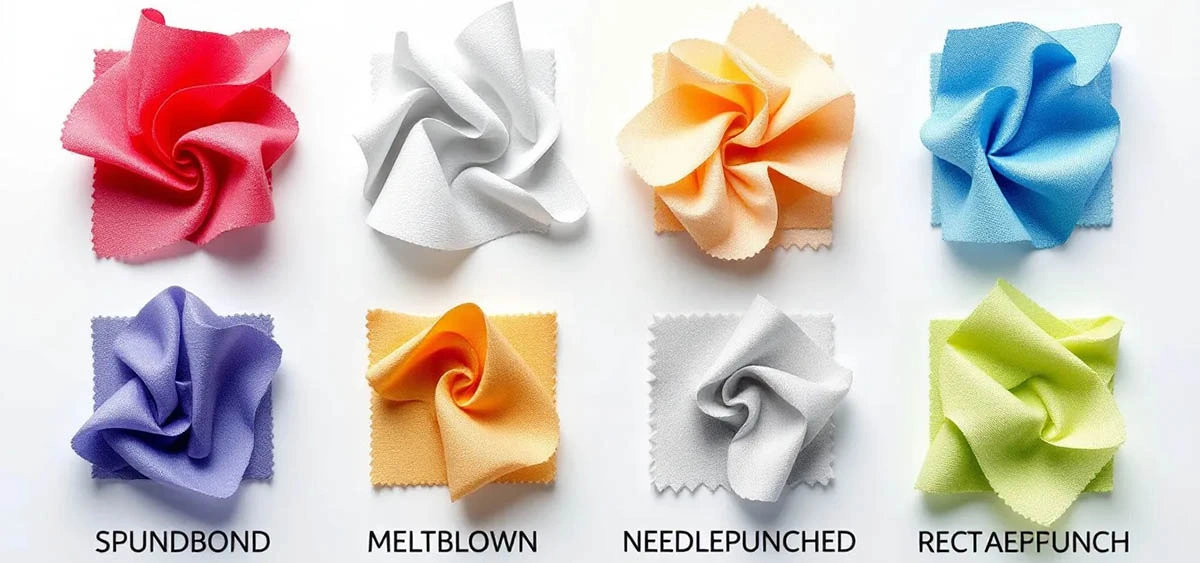

Types of Nonwoven Fabrics

Various types of nonwoven fabrics exist, each designed for specific applications. These fabrics can be single-use or highly durable, depending on their intended use. Properties like absorbency, liquid repellence, resilience, strength, and filament barrier can be customized to meet industry needs.

Primary types of nonwoven fabrics include spunbond, spunlace, and meltblown nonwovens. Each type features unique characteristics and applications, suitable for a variety of products. In the following subsections, we will delve into the specifics of each type, exploring their production processes and common uses.

Spunbond Nonwovens

Produced through a continuous process where fibers are spun and directly formed into a woven web, spunbond nonwovens are cost-effective for hygiene applications. This method allows for rapid manufacturing, resulting in low-cost products ideal for single-use items.

Spunbond nonwovens are commonly used in hygiene products, medical textiles, and agricultural coverings. Rising disposable incomes and increased hygiene awareness make emerging markets in Asia-Pacific promising areas for growth.

Spunlace Nonwovens

Known for their exceptional softness and strength, spunlace nonwovens are ideal for personal care items like wipes and medical products. The manufacturing process uses high-pressure water jets to entangle fibers, enhancing their strength and texture.

These fabrics are highly absorbent and are often used in personal care products, such as wipes and cosmetic pads. Their combination of softness and durability makes spunlace nonwovens popular in the market.

Meltblown Nonwovens

Meltblown fabrics are created by extruding molten polymer through a spinneret, producing fine fibers with excellent filtration capabilities. These properties are essential in medical applications like surgical masks and protective clothing.

In industrial settings, meltblown fabrics are used in filters and absorbents for their high filtration efficiency. The exceptional filtration capabilities of meltblown nonwovens ensure their continued demand in both medical and industrial sectors.

Materials Used in Nonwoven Fabrics

Nonwoven fabrics use a variety of materials, both synthetic and natural. Polypropylene is a key synthetic material valued for its durability and moisture resistance. Synthetic nonwovens made from polypropylene and polyester offer excellent strength and versatility.

Natural fibers like cotton and wood pulp offer eco-friendly options for nonwoven fabrics. These materials are often biodegradable, making them suitable for sustainable applications. Cotton fibers, in particular, are valued for their softness and comfort, making them ideal for personal care products.

In the following subsections, we will explore the specific properties and benefits of synthetic and natural nonwovens, highlighting their roles in the nonwoven fabrics industry.

Synthetic Nonwovens

Polypropylene’s excellent thermal and chemical resistance makes it widely used in nonwoven fabrics for various applications. Its durability and low cost make it one of the most popular synthetic fibers in nonwoven production.

Favored for their strength and versatility, polyester nonwovens are used in applications requiring high durability. However, the nonwoven industry faces challenges with the unstable pricing of raw materials, particularly petroleum-based synthetic polymers.

Natural Nonwovens

Cotton and wood pulp are commonly used natural materials in nonwoven fabric production. Cotton’s softness and breathability make it popular in personal care products. Wood pulp provides excellent absorbency, making it a valuable material for nonwoven fabrics.

These natural materials are biodegradable, contributing to the eco-friendliness of nonwoven fabric applications.

Technologies in Nonwoven Fabric Production

The production of nonwoven fabrics involves diverse techniques that cater to specific industrial needs. Key technologies in nonwoven fabric manufacturing include spunmelt, drylaid, and wetlaid processes, each offering unique methods for producing nonwoven materials.

A variety of bonding techniques, including chemical, thermal, and mechanical methods, are used to create bonded nonwoven fabrics that can withstand heat, often utilizing thermally binders. These methods allow for the customization of nonwoven fabrics, ensuring they meet the specific requirements of various applications.

In the following subsections, we will delve into the details of spun-melt, drylaid, and wetlaid technologies, exploring their processes and applications.

Spun-Melt Technology

Spun-melt technology combines spunlaid and meltblown processes to produce nonwoven fabrics directly from thermoplastic polymers. This technology is crucial for creating durable fabrics used in hygiene and medical products.

Advancements in spun-melt technology enhance product quality and reduce production costs, stimulating market growth. These innovations ensure that nonwoven fabrics produced using spun-melt technology stay competitive and high-performing.

Drylaid Technology

Drylaid technology involves:

-

Using mechanical means to process fibers into a web without water

-

Creating webs from dry fibers using air or mechanically methods

-

Producing versatile fabrics adaptable for various applications

The drylaid process uses staple fibers that are opened, mixed, and formed into a web with roller cards. This technology allows for the production of nonwoven fabrics with specific characteristics tailored to different industrial needs.

Wetlaid Technology

Similar to paper-making, wetlaid technology forming a web formation from a slurry of fibers and water, producing a uniform nonwoven sheet. This method allows for the production of high-quality fabrics used in filtration and absorbent products.

In wetlaid technology, short fibers are suspended in water, producing uniform nonwoven sheets with precise specifications. The consistency and quality of fabrics produced using this method make wetlaid technology a valuable process in the nonwoven industry.

Applications of Nonwoven Fabrics

Nonwoven fabrics are essential in various industrial applications, from healthcare to automotive. Their unique properties ensure continued demand across different sectors, making them suitable for a wide range of products.

Nonwoven fabrics are used in various sectors:

-

In the healthcare sector, for creating disposable items like surgical gowns, masks, and wound dressings.

-

In personal care, in products such as diapers and feminine hygiene items due to their softness and absorbency.

-

In the automotive industry, in components that enhance vehicle lightweighting and improve fuel efficiency.

The following subsections will explore these end use applications in detail, highlighting the importance of nonwoven fabrics in each sector.

Healthcare Sector

The healthcare sector’s demand for nonwoven products is driven by increased hygiene awareness and safety requirements. Nonwoven fabrics are crucial for creating disposable medical items such as:

-

Surgical gowns

-

Masks

-

Wound dressings These items provide essential barriers against contaminants. The high filtration efficiency of meltblown nonwoven fabrics makes them indispensable in medical applications, ensuring patient and healthcare worker safety.

With growing healthcare needs and population, Asia-Pacific accounted for a significant share of the global nonwoven fabrics market in 2023. The region’s expanding healthcare sector highlights the importance of nonwoven materials in addressing the increasing demand for hygiene and medical products.

Personal Care Products

In personal care products, nonwoven fabrics provide essential features like softness and absorbency. Diapers and feminine hygiene items rely on nonwoven materials for comfort and effectiveness. Their absorbent properties make nonwoven fabrics ideal for personal hygiene products, maintaining their everyday significance.

Innovations aimed at reducing waste have led to the development of 100% recyclable diaper closures made from renewable PLA materials. Such advancements not only enhance the functionality of personal care products but also align with the growing demand for sustainable nonwoven materials.

Automotive Industry

In the automotive industry, nonwoven fabrics are used for:

-

Lightweight components to enhance fuel efficiency and reduce vehicle weight

-

Sound insulation

-

Interior trims

-

Filtration systems They play a crucial role in automotive design and performance.

The shift towards lightweight, fuel-efficient vehicles boosts demand for nonwoven materials in various automotive applications. Nonwoven fabrics offer durability and versatility, meeting the industry’s standards while supporting environmental sustainability, including innovations from Freudenberg performance materials.

Sustainability in the Nonwoven Industry

Sustainability is becoming increasingly important in the nonwoven industry, driven by a rising focus on eco-friendly practices and consumer preferences. The demand for biodegradable nonwoven materials is growing, as consumers and industries alike seek to reduce their environmental impact.

Demand for sustainable materials that align with eco-friendly preferences is shaping the future of the nonwoven market. Manufacturers are adopting innovative processes to enhance sustainability and efficiency, particularly through developing biodegradable nonwovens.

In the following subsections, we will explore sustainable nonwovens and industry initiatives aimed at promoting eco-friendly practices within the nonwovens industry and the nonwoven fabrics industry.

Sustainable Nonwovens

Producing nonwoven fabrics poses significant environmental challenges, including waste generation and the carbon footprint of synthetic materials. To address these issues, manufacturers are developing biodegradable nonwoven materials for more eco-friendly end-of-life solutions.

Natural fibers like cotton and wood pulp are valued for their environmental friendliness and biodegradability, contributing to the production of sustainable nonwoven products. These materials break down faster than synthetic alternatives, reducing their environmental footprint and promoting sustainability.

Industry Initiatives

Manufacturers are implementing Sustainability Report to track and communicate their environmental impact. These reports set benchmarks for eco-friendly practices and encourage sustainable materials adoption.

Consumer demand for eco-friendly products drives nonwovens manufacturers to innovate and offer more sustainable nonwoven options. Regulations and collaboration among stakeholders are also driving the industry towards sustainable practices, ensuring that nonwoven fabrics meet both environmental and consumer expectations.

Challenges Facing the Nonwoven Industry

The nonwoven industry faces several challenges, including the need for sustainability and the volatility of raw material prices. As the industry focuses on mitigating environmental impacts associated with traditional materials, it must also address the rising costs and unstable pricing of synthetic polymers.

Environmental concerns, particularly related to microplastic pollution, are growing among customers. The industry must innovate and optimize to follow regulatory guidelines to reduce its environmental footprint and meet consumer demand for sustainable products.

Raw Material Volatility

The nonwoven sector is currently grappling with price fluctuations of essential raw materials, which can affect production costs and market stability. Volatile prices of synthetic polymers, largely influenced by crude oil market volatility, pose a major issue for manufacturers in the nonwoven sector.

Global supply chain issues and market demand drive up costs of petroleum-based polymers, crucial for nonwoven fabrics. These fluctuations can disrupt production schedules and impact profitability, presenting a significant challenge for the nonwoven industry.

Environmental Concerns

Producing nonwoven fabrics can have significant environmental implications, particularly regarding waste and pollution. As awareness of microplastic pollution grows, consumers are increasingly voicing concerns about the sustainability of synthetic nonwoven fabrics.

Innovations and adherence to regulatory guidelines are essential for reducing environmental impacts. The industry must continue to develop eco-friendly materials and processes to address these environmental concerns and meet consumer expectations for sustainable products.

Future Outlook of the Nonwoven Industry

The future of the nonwoven industry will focus increasingly on sustainability and innovation in business. Leading companies emphasize developing eco-friendly and biodegradable materials to enhance environmental benefits. This sustainability shift is shaping the industry’s growth and future direction.

Technological advancements in nonwoven production are expected to drive market growth and create new applications. Innovations like integrating nanofibers and advancements in spun-lay technology are anticipated to enhance product performance and broaden nonwoven fabric applications.

In the following subsections, we will explore the technological advancements and market opportunities that will shape the future of the nonwoven fabrics market.

Technological Advancements

Innovations in nonwoven technology, including nanofiber integration and new technologies, are expected to create new applications and enhance product performance. These advancements will improve the efficiency of nonwoven production and broaden its application in various industries.

Spun-lay technology is anticipated to significantly impact the future of nonwoven fabrics, offering enhanced quality and cost efficiency. These technological advancements ensure that nonwoven materials remain competitive and high-performing in the global market.

Market Opportunities

Emerging applications for nonwoven fabrics, such as hygiene products, medical supplies, and filtration materials, showcase diversified market potential. Increasing demand for personal care products like wipes and feminine hygiene items drives growth opportunities in the sector.

Regions like Asia-Pacific and North America are expected to lead the world’s market growth, driven by rising industrial applications and sustainable material demand. Innovations in biodegradable nonwoven fabrics and smart textiles expand market opportunities, ensuring continued growth and development.

Summary

The nonwoven industry is experiencing significant growth, driven by its versatility and widespread applications across various sectors. Key market drivers include the healthcare sector’s demand for disposable products, public hygiene awareness, and technological advancements in production methods. Regional insights highlight the leading markets in Asia-Pacific, North America, and Europe, each contributing to the industry’s expansion.

Sustainability is a critical focus for the nonwoven industry, with manufacturers developing eco-friendly materials and adopting innovative processes to reduce environmental impact. Despite challenges such as raw material volatility and environmental concerns, the industry’s future outlook is promising, with technological advancements and market opportunities paving the way for continued growth. As the nonwoven industry evolves, it will continue to play a vital role in addressing the needs of various sectors while promoting sustainability and innovation.

Frequently Asked Questions

What is driving the growth of the nonwoven fabrics market?

The nonwoven fabrics market is primarily growing due to increasing demand from the healthcare sector for disposable products, heightened public hygiene awareness, and advancements in production technologies. These factors collectively contribute to the market's expansion.

Which regions are leading the nonwoven fabrics market?

Asia-Pacific, North America, and Europe are the leading regions in the nonwoven fabrics market, driven by increasing healthcare demands and industrial applications.

What are the main types of nonwoven fabrics?

The main types of nonwoven fabrics are spunbond, spunlace, and meltblown, each characterized by distinct properties and various applications. Understanding these differences is essential for selecting the appropriate fabric for specific uses.

How is the nonwoven industry addressing sustainability?

The nonwoven industry is addressing sustainability by developing biodegradable materials, adopting eco-friendly practices, and implementing sustainability reports to effectively track and communicate their environmental impact.

What challenges does the nonwoven industry face?

The nonwoven industry faces significant challenges, including raw material volatility, environmental concerns, and a pressing need for sustainable practices. Addressing these issues is crucial for the industry's long-term viability.

Contact MH

MH offers nonwoven fabric. Please contact us for more details or inquiries. We're here to help!