Choosing the Best Nonwoven Interfacing for Your Sewing Projects

Looking to add structure to your sewing projects? Nonwoven interfacing is the solution. This article covers what it is, how to use it, and which type to choose for your needs.

Key Takeaways

-

Nonwoven interfacing adds structure to fabrics and is versatile, allowing cutting in any direction without worrying about grainlines.

-

Choosing between fusible and sew-in interfacing depends on the project needs; fusible is quicker while sew-in offers more durability and control.

-

Proper application and care of nonwoven interfacing are essential for achieving a professional finish and maintaining garment quality over time.

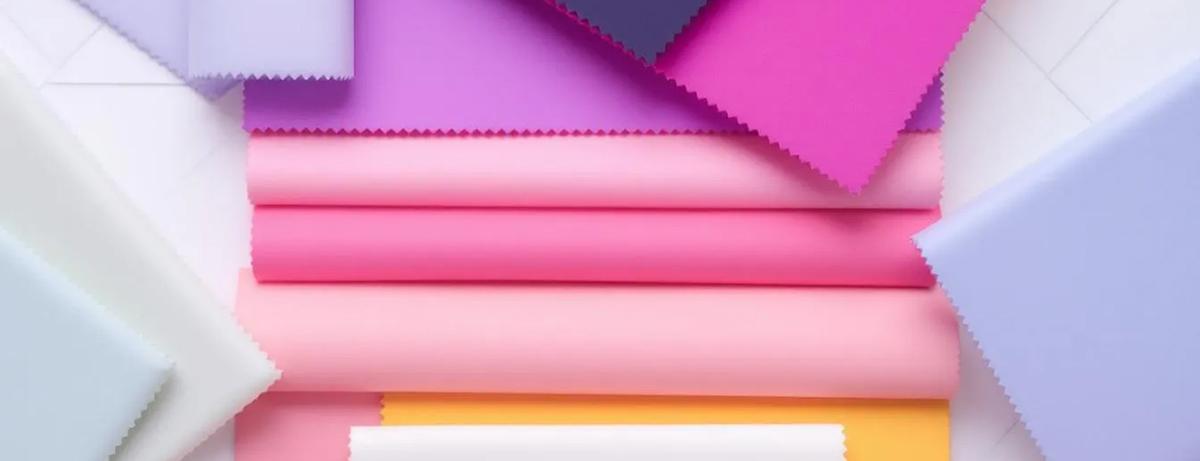

Understanding Nonwoven Interfacing

Non woven interfacing adds structure and support to fabrics, reinforcing high-stress areas like collars, cuffs, and button plackets. Unlike woven interfacing, which is made by weaving threads together, non woven interfacings are produced by bonding fibers together, giving it a distinct paper-like feel. This characteristic makes it incredibly versatile, as it can be cut in any direction without worrying about grainlines. Wovens can also provide a different texture and appearance in various applications.

A notable feature of non woven fusible interfacing is its ease of application, particularly with fusible options. These have glue dots that bond with the fabric when heated, creating a lasting attachment. However, nonwoven interfacing tends to be less durable than woven varieties when frequently washed.

Grasping these basic characteristics enables informed decisions for your projects. Whether adding structure to a lightweight blouse or reinforcing a heavy coat, understanding nonwoven interfacing makes a big difference for a constructed professional finish.

Types of Nonwoven Interfacing

Nonwoven interfacing comes in various types, each suited for different applications. The main types include lightweight, medium-weight, and heavyweight nonwoven interfacings, each offering distinct features and benefits.

Lightweight nonwoven interfacing provides minimal body while adding stability to delicate fabrics like silk or chiffon. It’s perfect for projects where you need to stabilize a little extra support without adding bulk on the right side and one side. A great product, shape flex is an excellent choice for these light weight applications.

On the other hand, medium-weight nonwoven interfacing adds a crisp drape, making it suitable for structured garments like shirts and dresses. This type of medium weight interfacing is versatile and often used in everyday sewing projects.

For projects that require significant structure, weight non woven heavyweight interfacing is the way to go. This type of non woven:

-

Is designed to completely stiffen the fabric

-

Is ideal for creating bags, hats, and other accessories that need to hold their shape

-

Has no grainline, so it can be cut in any direction, simplifying the process

Fusible vs. Sew-in Nonwoven Interfacing

Choosing between fusible and sew-in options is a key decision. Fusible interfacing is favored for its simplicity. With an adhesive side that bonded with heat, it’s a quick and convenient choice for many projects, ideal for stress-prone areas like button plackets and fused collars, making it easy to fuse them securely.

Sew-in interfacing, requiring stitching, takes more time but offers greater flexibility and control. It’s often chosen for high-stress applications and heavier fabrics needing extra sewn sticking durability.

Your choice between fusible and sew-in interfacing depends on fabric type and project goals. Fusible interfacing works well for quick applications, while sew-in options offer more stability and control, ideal for intricate designs.

Applications of Nonwoven Interfacing

Nonwoven interfacing is incredibly versatile and can be used in various sewing projects to add structure and support. One common use is in making bags, where it helps create a sturdy shape and prevents the fabric from sagging. Whether you’re making a tote, a clutch, or a backpack, nonwoven interfacing can give your bag the professional finish it needs.

Another popular application is in garment construction. Nonwoven interfacing is often used in collars, cuffs, and button plackets to reinforce these high-stress areas and maintain their shape. It is also used in costumes and accessories to add stiffness and structure, making the final product look polished and well-made. Tricot interfacing is another option that can be considered for similar applications.

In recent years, nonwoven interfacing has become particularly useful in creating face masks due to:

-

Its ability to add a layer of stiffness without adding bulk, making it ideal for personal protective equipment.

-

The lack of a grain line, which allows for versatile cutting.

-

Its ease of use and adaptability to different mask patterns, especially when facing various design challenges, including facings.

How to Apply Nonwoven Fusible Interfacing

Proper application of nonwoven fusible interfacing is key to a smooth, professional finish. Begin by pre-washing and pressing your fabric to prevent bubbling. Then, identify the adhesive side of the interfacing, usually slightly raised and shiny.

To apply interfacing to fabric:

-

Position the adhesive side of the interfacing on the fabric’s wrong side.

-

Use a hot iron and a damp press cloth to apply heat and steam, activating the adhesive.

-

Hold the iron still for about 15 seconds on medium-weight fabrics to ensure bonding.

-

Avoid moving the iron to prevent shifting and wrinkles.

Allow the fabric to cool completely after applying interfacing to set the adhesive and prevent distortion. This ensures a smooth, secure bond.

Tips for Working with Nonwoven Interfacing

Working with nonwoven interfacing is easier with some key tips. First, match the interfacing weight to your fabric. This prevents project issues and ensures a professional finish. Generally, choose interfacing with similar or lighter weight and less drape than the fabric.

When cutting interfacing, consider both its drape and weight. For stable fabrics, cut interfacing directly using the pattern piece for accuracy. For heavier fabrics, cut it smaller to reduce seam bulk and ensure it is caught in stitching.

Test interfacing on a fabric scrap to check weight compatibility before finalizing. This step can save time and frustration, ensuring the best result for your project.

Where to Buy Nonwoven Interfacing

Finding the right nonwoven interfacing is easy when you find interfacing options available for purchase. Most fabric stores and big-box craft stores carry a variety of nonwoven interfacing options. These stores are great for in-person shopping, allowing you to feel the interfacing and match it to your fabric.

For those who prefer online shopping, major online fabric retailers often have a wide range of nonwoven interfacing materials quantity options available for purchase. Online shopping offers the convenience of browsing and comparing different types and price from the comfort of your home.

If you need nonwoven interfacing in bulk, consider wholesale suppliers like MH, which offer bulk purchasing options for large quantities. When selecting a supplier, consider factors such as pricing, availability, and shipping options to ensure the best purchase experience.

Caring for Fabrics with Nonwoven Interfacing

Caring for garments with nonwoven interfacing requires gentle handling to maintain their quality. It’s best to wash these items inside out on a gentle cycle at temperatures up to 30°C. This helps protect both the fabric and the interfacing from damage.

Avoid tumble drying items with nonwoven interfacing, as the heat can cause the adhesive to reactivate and potentially come unstuck. Instead, lay the item flat in a well-ventilated area to dry. If ironing is necessary, use a cool iron to press the fabric, taking care not to apply too much heat.

Following these care instructions will help ensure that your clothing garments and projects maintain their structure and look their best over time.

Summary

Choosing the right nonwoven interfacing is essential for achieving a professional finish in your sewing projects. By understanding the different types of nonwoven interfacing and their applications, you can make informed decisions that enhance the quality and durability of your creations.

From lightweight to heavyweight options, nonwoven interfacing offers versatility and ease of use. Whether you’re reinforcing a delicate blouse or constructing a sturdy bag, there’s a nonwoven interfacing that’s perfect for the job. Remember to follow the proper application techniques and care instructions to ensure the longevity of your projects.

With the knowledge and tips provided in this guide, you’re now equipped to confidently select and use nonwoven interfacing in your sewing endeavors. Happy sewing!

Frequently Asked Questions

What is the difference between nonwoven and woven interfacing?

The key difference between nonwoven and woven interfacing lies in their construction; nonwoven interfacing is fiber-bonded without a grainline, offering a paper-like texture, whereas woven interfacing is crafted from interlaced threads, providing greater durability and a fabric-like quality.

When should I use lightweight nonwoven interfacing?

You should use lightweight nonwoven interfacing for delicate fabrics like silk or chiffon that require minimal body and stability. This choice ensures a seamless and professional finish for your sewing projects.

How do I apply fusible interfacing correctly?

To apply fusible interfacing correctly, place the adhesive side against the wrong side of your pre-washed and pressed fabric. Then, use a hot iron with a damp press cloth to bond them together, ensuring you let it cool completely after pressing. This will ensure a strong and lasting connection between the fabric and interfacing.

Where can I buy nonwoven interfacing?

You can buy nonwoven interfacing at fabric stores, big-box craft stores, and major online retailers. For bulk options, consider wholesale suppliers such as MH.

How should I care for garments with nonwoven interfacing?

To care for garments with nonwoven interfacing, wash them inside out on a gentle cycle at temperatures up to 30°C, and lay them flat to dry instead of tumble drying. If needed, use a cool iron for any touch-ups.

Contact MH

MH offer nonwoven interfacing fabric. Please contact us for more details or inquiries. We're here to help!