Why Select Single Fold Bias Tape 1/2 Inch for Your Factory?

In today’s competitive garment and textile manufacturing landscape, achieving professional edge finishes efficiently can make the difference between profit and loss. Single fold bias tape 1/2 inch represents one of the most versatile and cost-effective solutions for manufacturers seeking consistent, high-quality results across diverse product lines. As a global B2B manufacturer and wholesale supplier of garment accessories, MH understands that every human touch in your production line matters, and the right bias tape can streamline operations while elevating your finished products.

This comprehensive guide explores everything you need to know about sourcing, specifying, and implementing single fold bias tape 1/2 inch in your manufacturing operations. Whether you’re finishing necklines on premium cotton blouses or binding edges on industrial workwear, understanding the technical specifications, material options, and application methods will help you make informed purchasing decisions that impact your bottom line.

What is Single Fold Bias Tape 1/2 Inch

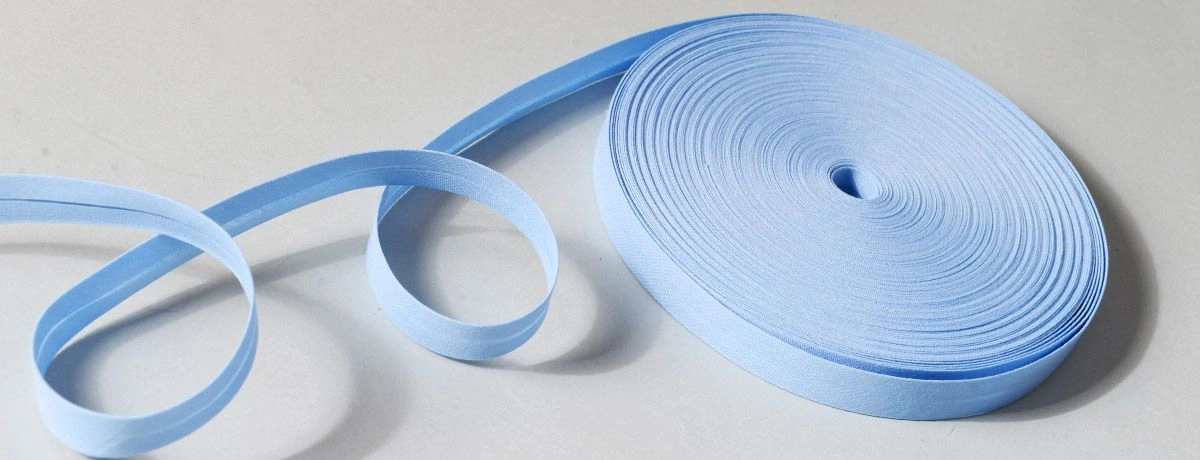

Single fold bias tape 1/2 inch is a pre folded fabric strip measuring 12.7mm in finished width, cut at a 45-degree angle to the fabric grain to maximize natural stretch and conformability. Unlike standard straight-grain binding, this bias-cut construction allows the tape to smoothly follow curves and contours without puckering or distorting the host fabric.

The “single fold” designation indicates that the tape has been folded once along each edge toward the center, creating clean, finished edges while maintaining a relatively flat profile. This construction differs significantly from double fold bias tape, which includes an additional center fold that creates a more enclosed binding solution. The 1/2 inch measurement refers to the total width when the tape is fully opened, providing manufacturers with a standardized specification for consistent results across production runs.

MH manufactures single fold bias tape 1/2 inch using precision folding equipment that ensures consistent fold lines and dimensional stability. The tape arrives ready for immediate application, eliminating the need for additional preparation steps in your production line. This pre folded configuration reduces labor costs and improves throughput efficiency, particularly important factors for manufacturers operating on tight margins.

The bias grain construction provides approximately 3-7% mechanical stretch, depending on the base fabric composition. This elasticity allows the tape to accommodate moderate stress without breaking or losing its shape, making it ideal for garments that experience regular movement and washing cycles.

Single Fold vs Double Fold vs Bias Binding: Key Differences

Understanding the distinctions between bias tape variants is crucial for selecting the optimal product for your specific manufacturing requirements. Each type serves different applications and offers unique advantages in terms of production efficiency and finished appearance.

Single Fold Bias Tape features edges folded toward the center with no additional folds, creating a relatively flat profile with approximately 2-3mm thickness. This construction makes it ideal for facings, where the tape is typically turned to the interior of the garment and provides a clean finish without excessive bulk. Manufacturing advantages include faster application speeds and reduced thread consumption compared to more complex binding methods.

Double Fold Bias Tape includes an additional center fold that creates a channel for encasing raw edges. While this provides superior edge protection and a more finished appearance on both sides of the fabric, it requires more precise positioning during application and increases material costs. The double fold construction is preferred for applications where both sides of the binding will be visible, such as quilt binding or decorative trim work.

Bias Binding serves as the umbrella term encompassing all bias-cut binding solutions. In B2B manufacturing contexts, this term often includes custom-manufactured binding tapes designed for specific applications, such as flame-retardant binding for industrial workwear or stretch binding for activewear.

For bulk production efficiency, single fold bias tape offers several key advantages. The streamlined application process reduces cycle time per garment, while the lower material thickness minimizes bulk in seam allowances. These factors contribute directly to improved productivity and reduced manufacturing costs, critical considerations for competitive pricing in global markets.

Material Specifications and Options

Cotton Single Fold Bias Tape

100% cotton construction remains the gold standard for applications requiring breathability, comfort, and natural feel against the skin. MH’s cotton single fold bias tape utilizes premium-grade cotton fabric with fiber lengths optimized for strength and consistent dye uptake. The pre-shrunk processing ensures dimensional stability through commercial wash cycles, eliminating concerns about post-production shrinkage that could affect garment fit.

Colorfastness specifications meet or exceed industry standards, with typical ratings of Grade 4 or higher for washing fastness and Grade 3-4 for light fastness. These performance characteristics ensure that vibrant colors maintain their intensity throughout the product lifecycle, protecting your brand reputation and reducing customer complaints.

Weight specifications range from 100-140 GSM depending on specific construction requirements. Lighter weights (100-110 GSM) work well for delicate fabrics and lightweight garments, while heavier constructions (120-140 GSM) provide enhanced durability for workwear and frequently laundered items.

Polyester and Blend Options

Polyester and polyester-blend single fold bias tape offers enhanced durability and dimensional stability for demanding applications. Common blend ratios include 65% polyester/35% cotton and 50%/50% blends, each providing distinct performance characteristics.

Pure polyester construction delivers maximum strength retention and resistance to stretching, making it ideal for applications where maintaining precise dimensions is critical. The synthetic fiber construction also provides superior resistance to fading and chemical degradation, important factors for industrial applications or garments exposed to harsh environments.

Polyester-cotton blends combine the comfort characteristics of cotton with the performance advantages of synthetic fibers. The 65/35 polyester-cotton blend offers optimal balance for most commercial applications, providing adequate comfort while maintaining dimensional stability and wash durability.

Mechanical stretch properties vary by blend ratio, typically ranging from 3-7% elongation at break. Higher polyester content generally increases stretch recovery and reduces permanent deformation under stress. Thickness specifications range from 0.20mm to 0.30mm, with tighter tolerances available for precision applications.

Manufacturing Applications

Garment Manufacturing Uses

Single fold bias tape 1/2 inch serves multiple critical functions in modern garment manufacturing, with applications spanning from basic edge finishing to decorative trim work. The versatility of this product makes it an essential component in diverse production environments.

Neckline finishing represents one of the most common applications, particularly for t-shirts, blouses, and casual dresses. The bias construction allows the tape to conform smoothly to curved necklines without creating wrinkles or stress points. Application typically involves positioning the tape along the neckline raw edge, stitching in place, then turning to the interior and securing with a second line of stitching or coverstitch operation.

Armhole binding for sleeveless garments and activewear requires tape that can accommodate the complex curves and movement stresses inherent in this application. The natural stretch of bias-cut tape provides the flexibility needed to maintain comfort while ensuring long-term durability. Professional application techniques include pre-stretching the tape slightly during application to prevent gapping or pulling after washing.

Hemming applications for curved edges and bias cuts benefit from the tape’s ability to follow irregular contours while providing a clean, finished appearance. This application is particularly valuable for circle skirts, handkerchief hems, and asymmetrical designs where traditional hemming methods would create bulk or distortion.

Seam finishing for unlined jackets and outerwear provides an economical alternative to more complex finishing methods. The tape can be applied to seam allowances to prevent fraying while adding minimal bulk to the finished garment. This application is especially valuable for mid-market products where cost control is critical.

Textile and Home Goods Applications

Beyond traditional garment manufacturing, single fold bias tape 1/2 inch serves important roles in textile and home goods production. These applications often require higher durability standards and may involve specialized performance requirements.

Quilt binding for commercial bedding production requires tape that can withstand repeated washing and maintain its appearance over extended use cycles. The binding process typically involves applying the tape to quilt perimeters using specialized binding attachment equipment. Tape selection must balance cost considerations with performance requirements, including wash durability and color retention.

Placemat and table linen edge finishing demands products that can withstand frequent laundering and potential exposure to staining agents. Polyester-blend constructions often perform better in these applications due to superior stain resistance and dimensional stability. Application methods may include both visible binding techniques and concealed facing applications.

Upholstery edge treatments and piping alternatives utilize the tape’s flexibility to create smooth transitions around furniture contours. The bias construction prevents bunching or puckering that could compromise the finished appearance. Selection criteria include compatibility with upholstery fabrics and adhesives, as well as compliance with fire safety standards where applicable.

Industrial textile applications requiring flexible binding include everything from tarpaulins to protective equipment. These applications often require specialized treatments such as water resistance, flame retardancy, or enhanced UV stability. Custom manufacturing capabilities allow MH to meet these specialized requirements while maintaining cost-effectiveness for volume production.

Bulk Sourcing and Wholesale Considerations

Minimum Order Quantities

Efficient bulk sourcing requires understanding the economic factors that drive minimum order quantities and delivery schedules. MH structures our MOQ requirements to balance manufacturing efficiency with customer flexibility, enabling both large-scale operations and growing businesses to access professional-quality products.

Standard Colors from our stock range carry a minimum order requirement of 500 yards per color, allowing smaller manufacturers to access professional-quality tape without excessive inventory investment. This MOQ level enables cost-effective production runs while maintaining reasonable per-unit pricing. Multiple colors can be combined within a single order to reach efficient shipping quantities.

Custom Colors require higher minimum quantities due to the setup costs associated with dye lot preparation and color matching procedures. Typical minimums start at 2,000 yards per custom color, with pricing advantages available for quantities exceeding 5,000 yards. Large-volume customers often negotiate annual contracts that guarantee pricing and delivery schedules for planned production requirements.

Mixed Color Pallets provide flexibility for manufacturers requiring smaller quantities of multiple colors. These arrangements allow combining different standard colors within a single order, typically requiring an aggregate minimum of 1,000 yards total. This approach works particularly well for fashion manufacturers following seasonal color trends or sample production requirements.

Volume Pricing structures reward larger commitments with progressively lower per-unit costs. Typical break points occur at 2,500 yards, 5,000 yards, and 10,000+ yards per color. Annual volume commitments can unlock additional discounts and priority allocation during peak demand periods.

Packaging and Logistics

Professional packaging and logistics management ensure your bias tape arrives ready for immediate production use while minimizing handling and storage costs. MH utilizes standardized packaging configurations designed for both automated handling equipment and manual operations.

Bulk Roll Packaging options include master rolls from 1,000 to 5,000 yards for high-volume operations requiring maximum efficiency. These configurations minimize packaging waste while reducing per-unit costs. Master rolls utilize heavy-duty cores designed to support the weight and prevent deformation during storage and handling.

Retail-Ready Packaging serves distributors and resellers requiring finished goods presentation. Options include individual cards, blister packs, and display boxes suitable for retail environments. Custom labeling and branding services support private label programs and brand development initiatives.

Custom Labeling and Branding capabilities include product labels, barcodes, instruction cards, and promotional materials. Digital printing technology enables cost-effective short runs while maintaining high-quality graphics and text clarity. Brand protection measures include tamper-evident packaging and authentication features for premium products.

Global Shipping Capabilities utilize our network of logistics partners to provide reliable delivery worldwide. Standard shipping options include ocean freight for cost-sensitive applications and air freight for time-critical requirements. Lead time planning tools help customers optimize their inventory management while maintaining production continuity.

Packaging specifications are optimized for container loading efficiency, with standard carton dimensions designed to maximize utilization while remaining within weight limits for safe manual handling. Documentation includes detailed packing lists, certificates of origin, and quality compliance certificates as required by destination markets.

Partner with MH for Your Single Fold Bias Tape Needs

As your trusted B2B manufacturing partner, MH combines decades of textile manufacturing expertise with modern production capabilities and global logistics support. Our comprehensive approach to customer partnership extends far beyond simply supplying product to encompass technical support, custom development, and long-term strategic planning.

Contact MH’s B2B Sales Team for personalized consultation on your bias tape requirements. Our experienced team understands the unique challenges facing garment manufacturers and can recommend optimal solutions based on your specific applications, volume requirements, and quality standards. Direct access to our technical staff ensures accurate specification development and smooth project implementation.

Request Custom Specifications for OEM/ODM projects requiring specialized performance characteristics or unique dimensions. Our engineering team can develop custom solutions for applications requiring enhanced stretch, special treatments, or non-standard widths. Prototype development capabilities enable testing and refinement before committing to full production tooling.

Schedule Facility Tours for large-scale partnership discussions and supply chain verification. Our modern manufacturing facilities demonstrate our commitment to quality and capacity planning, while direct interaction with our production team provides insight into our capabilities and processes. These visits often prove valuable for customers requiring supplier audits or relationship development.

Access Technical Support for application-specific requirements and troubleshooting assistance. Our team includes experienced textile engineers who can provide guidance on application techniques, equipment recommendations, and quality optimization. This support extends throughout the customer relationship to ensure ongoing success.

Connect with Regional Distributors and authorized resellers for localized support and reduced delivery times. Our distributor network provides local inventory and technical support while maintaining consistent quality standards and pricing structures. This approach offers the benefits of global manufacturing scale with the responsiveness of local partnerships.

Ready to enhance your manufacturing efficiency with professional-quality single fold bias tape 1/2 inch? Contact MH today to discuss your requirements and discover how our expertise can support your success. Whether you need sample quantities for evaluation or bulk orders for full production, our team stands ready to deliver the quality and service your business deserves.

Visit our website to explore our complete product catalog, verify current stock availability, and add samples to your cart for immediate evaluation. Take the first step toward improved manufacturing efficiency by partnering with MH for all your bias tape requirements. Our commitment to quality, service, and partnership ensures your success in today’s competitive marketplace.