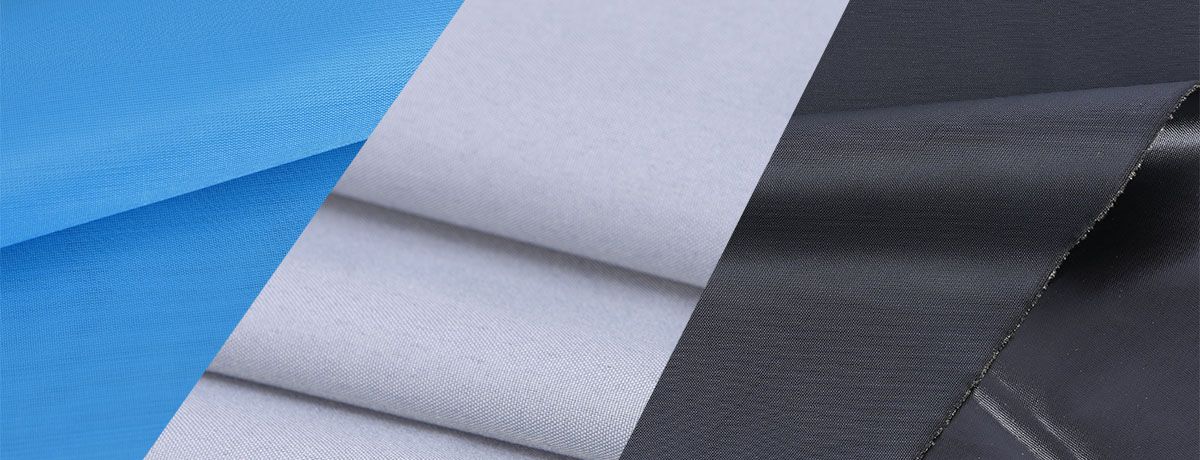

Taffeta vs Pongee vs Oxford: Which Is Better for Lining Fabric?

Introduction

When manufacturers select lining fabrics for garments, bags, or functional products, the decision often comes down to three widely used materials: taffeta, pongee, and oxford. Although all three are traditional fabrics made from chemical fibers such as polyester or nylon, their weaving structure, thickness, cost, and application focus are quite different.

For buyers in the decision stage, understanding these differences—from warp and weft yarn structure to dyeing and finishing processes—is essential for choosing the most suitable lining fabric. This article provides a practical, technical comparison to support informed B2B sourcing decisions.

Fabric Structure & Weaving Process Overview

Taffeta Fabric

Taffeta is a plain weave fabric, constructed with evenly interlaced warp and weft yarns. It is known for its smoother, crisper feel and is lighter in weight compared to Oxford fabrics. In industrial use, it is most commonly produced as polyester taffeta, a stable chemical fiber fabric.

Key structural features:

-

Plain weave structure

-

Thin and smooth surface

-

Uniform warp and weft yarn distribution

-

Suitable for lightweight linings

Taffeta is a traditional fabric, recognized for its crisp, smooth feel, formal look, and distinctive rustling sound ("scroop"). It holds dye exceptionally well, resulting in vibrant, long-lasting colors and a beautiful appearance with soft or bright hues. Taffeta is available in both bright and softer colors, making it suitable for casual and children's wear. Polyester taffeta is an all-polyester thin fabric, available in various specifications such as 190T and 250T, and is widely used for jackets, umbrellas, sportswear, and various types of clothing linings due to its attractive appearance, affordability, and popularity among ordinary people. Its beautiful appearance and low price make it a favorite for casual and sportswear. Taffeta is also commonly used for high-end formal wear, decorative purposes like curtains and tablecloths, and for creating high-quality artificial flowers. Note that taffeta can develop permanent creases if not stored properly.

Pongee Fabric

Pongee is a type of cloth that is a plain weave or light weave fabric, usually made from polyester pongee or nylon, and is known for its flat and smooth surface. Pongee fabric is lightweight, has good elasticity and gloss, and is light in texture but strong in wear resistance, making it suitable for a wide range of applications including clothing, umbrellas, and raincoats. Polyester pongee is often used for raincoats and umbrellas due to its waterproof qualities, flat and smooth surface, light texture, and strong wear resistance. Pongee is also popular for casual wear and children's clothing (children's wear) because of its softness, breathability, and appealing look, making it a preferred choice for children's apparel and linings. Note that silk pongee can wrinkle more easily than its synthetic counterparts. Both polyester pongee and polyester taffeta are made from polyester, but pongee is softer and offers more variety in weaving styles compared to taffeta.

Structural characteristics:

-

Plain weave with softer yarn tension

-

More flexible hand feel

-

Available as half-elastic pongee, semi-elastic pongee, or full elastic pongee depending on yarn selection

-

Slightly thicker than taffeta in many cases

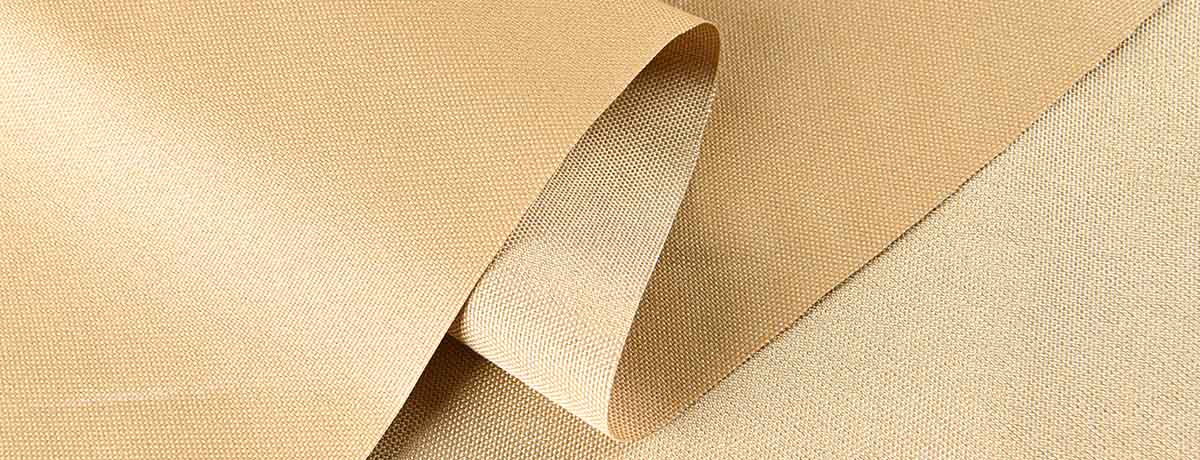

Oxford Fabric

Oxford fabric is a type of cloth commonly made from cotton, polyester, or nylon fabric, and is one of several different fabrics used for linings and a wide range of applications. Oxford fabric is generally a sturdy fabric and is considered a lighter alternative to pack cloth. It is characterized by its basket weave structure, which creates a visible texture and enhances its strength for various uses.

Oxford fabric uses a basket or oxford weave, combining multiple warp and weft yarns. This basket weave not only gives Oxford fabric its distinctive texture but also contributes to its durability and resistance to wear and tear. Oxford fabric is breathable and comfortable, making it suitable for extended wear in various climates. Its sturdy construction and durability make it a popular choice for outdoor gear such as tents and backpacks.

Structural characteristics:

-

Thicker construction

-

Stronger yarn bundles

-

Higher fabric weight

-

Designed for strength and durability

Thickness & Weight Comparison

Fabric thickness directly affects lining performance and final product weight.

-

Taffeta: thin, light, smooth — ideal for lightweight garment and bag linings

-

Pongee: medium thickness, softer — suitable for flexible or water-resistant linings

-

Oxford: thick and heavy — adds structure and abrasion resistance

For products where weight control is important (e.g. jackets, sleeping bags, tents), taffeta or pongee is often preferred over oxford.

Raw Materials & Chemical Fiber Differences

All three fabrics are commonly produced using chemical fibers and natural fibers, mainly:

-

Polyester (most common for taffeta and pongee)

-

Nylon fabric (used in pongee and oxford for higher strength, with distinct tactile qualities and manufacturing processes)

-

Cotton (a traditional and versatile option for Oxford cloth, valued for its texture and breathability; available in varieties such as 100% cotton)

Material selection influences:

-

Fabric softness

-

Durability

-

Cost

-

Drying speed and wash performance

Polyester-based linings generally offer better cost stability and easier bulk supply. Polyester also has good UV resistance and does not stretch or sag as much as nylon when wet.

Dyeing & Finishing Process Comparison

The dyeing and finishing process plays a key role in fabric performance.

-

Taffeta: supports stable dyeing, bright colors, smooth finish

-

Pongee: often combined with waterproof coating or water-repellent finishing

-

Oxford: may receive PU coating or PVC coating for durability and waterproof performance

The finishing process applies environmental protection dyeing, coating, and post-dyeing treatments such as PVC and PU coating, calendering, embossing, and high-temperature ironing to improve fabric appearance, durability, and functionality.

Finishing processes determine whether the fabric is suitable for lining accessories, waterproof linings, or industrial applications.

Application Scenarios for Lining

Taffeta for Lining

Commonly used for:

-

Garment linings (including jackets, uniforms, and high-grade clothing linings)

-

Sportswear

-

Bag linings

-

Lightweight lining accessories

-

Umbrellas

-

Artificial flowers (due to its durability and beautiful appearance)

-

Decorative items where a beautiful appearance, soft colors, and charming luster are desired

Pongee for Lining

Commonly used for:

-

Waterproof linings

-

Umbrellas and shower curtains

-

Raincoats and waterproof clothing, as polyester pongee is often treated with a waterproof coating for use in rainwear, jackets, and sunshades

-

Sleeping bags and tents

-

Products requiring softer touch and quick drying

-

Casual wear and children's wear, thanks to pongee fabric's good elasticity, gloss, and appealing softness

Oxford for Lining

Commonly used for:

-

Heavy-duty bag linings

-

Tool bags and industrial covers

-

Applications requiring abrasion resistance

Cost Comparison in Bulk Manufacturing

From a B2B perspective, cost is closely linked to structure and raw materials.

-

Taffeta: most cost-effective, wide specifications, easy scaling

-

Pongee: moderate cost, varies by elasticity and finishing

-

Oxford: highest cost due to yarn thickness and weaving complexity

For large-volume orders, polyester taffeta often offers the best cost–performance balance.

Performance Trade-Offs

Each fabric offers unique characteristics:

-

Taffeta: light, smooth, economical

-

Pongee: soft, flexible, suitable for waterproof applications

-

Oxford: strong, thick, long service life

For women's clothing fabrics, nylon fabric is often used, and the choice between taffeta, pongee, taslon, or other materials depends on the specific characteristics required for the end use.

There is no single fabric suitable for all lining needs; selection depends on detailed requirements and end use.

MH as a Supplier of Lining Fabrics

As an experienced supplier of taffeta, pongee, and oxford fabrics, MH supports manufacturers with complete lining fabric solutions. MH supplies polyester and nylon-based fabrics produced through controlled weaving and finishing processes, ensuring consistent quality, complete specifications, and stable bulk supply.

MH provides:

-

Polyester taffeta for lightweight linings

-

Polyester and nylon pongee for waterproof and flexible linings

-

Oxford fabric for durable lining applications

-

Multiple finishing options, including waterproof coating

-

Bulk supply for OEM and wholesale buyers

With a focus on professional B2B cooperation, MH helps buyers select the right fabric based on structure, cost, and application requirements.

MOQ, Packing & Bulk Supply Considerations

All three lining fabrics are supplied mainly for bulk production:

-

Practical MOQs for manufacturers

-

Roll packing for efficient handling

-

Stable supply for long-term projects

These conditions support predictable production planning and smooth communication between suppliers and buyers.

Conclusion

Taffeta, pongee, and oxford fabrics each serve different lining needs. Their differences in weaving structure, raw materials, thickness, finishing processes, and cost make them suitable for distinct applications.

For B2B buyers, understanding these differences—and sourcing from experienced suppliers such as MH—ensures that lining fabrics meet performance requirements, cost targets, and long-term production goals.