What Is Microfiber? Understanding Its Benefits and Applications

Microfiber is a synthetic fabric made from ultra-fine fibers, less than one denier thick. It is known for being soft, absorbent, and water-resistant. Used in items like cleaning cloths, bedding, and apparel, microfiber offers many practical benefits. Read on to learn what is microfiber, how it’s made, and its diverse applications.

Key Takeaways

-

Microfiber fabric is a synthetic textile made from ultra-fine fibers, known for its softness, high absorbency, and resistance to stains, making it suitable for a wide range of applications from cleaning to apparel.

-

The production process of microfiber involves blending polyester and polyamide, followed by a series of steps including extrusion and weaving, which enhance its texture, durability, and performance.

-

Despite its advantages, microfiber contributes to plastic pollution as washing releases microplastics into waterways, prompting a growing demand for eco-friendly alternatives and sustainable practices in the textile industry.

What Is Microfiber Fabric?

Microfiber fabric is a synthetic fabric crafted from ultra-fine fibers, typically measuring less than one denier, making it significantly finer than traditional textiles like cotton or polyester. These fibers can be as small as 0.2 deniers, allowing microfiber to possess a soft feel, high absorbency, and resistance to stains and water. This unique combination of properties stems from the dense and rich texture of microfiber, which is thinner and more affordable than many other fabrics, offering similar comfort without the hefty price tag.

The popularity of microfiber is largely due to its soft sateen feel and moisture-wicking properties, making it a favored choice for various applications, from cleaning cloths to apparel and home textiles. Microfiber bedding, towels, and sheets, for instance, are highly sought after for their luxurious feel and practicality.

Compared to natural fibers like cotton, microfiber is less expensive yet provides similar, if not superior, comfort and functionality.

Composition of Microfiber

Microfiber is typically made from a blend of polyester and polyamide, which together create a fabric that is both durable and absorbent. The manufacturing process involves melding polyester fibers and tiny polyamide strips, which enhances the microfiber’s tensile strength and absorbency.

This combination ensures that microfiber fabrics perform excellently in a variety of applications, from cleaning cloths to apparel, due to their durability and high performance.

How Is Microfiber Fabric Made?

The production of microfiber fabric involves the following steps:

-

Blending polyester and polyamide.

-

Achieving the blend through a vertical extrusion process, where the materials are heated and fused together.

-

Extruding the resulting blend to create ultra-fine fibers.

-

Weaving these ultra-fine fibers into fabric sheets.

-

Knitting the woven microfibers into large bolts of fabric, ready for further manufacturing.

The process doesn’t end there. Microfiber production involves several stages, including:

-

Yarn production

-

Weaving techniques

-

The critical splitting and dyeing processes Each stage plays a vital role in determining the final quality and characteristics of the microfiber fabric.

Microfiber Yarn Production

Microfiber yarn production involves the following steps:

-

Heating and mixing polyester and polyamide pellets until they melt, forming a homogeneous blend.

-

Extruding this blend through a spinneret to create ultra-fine fibers.

-

Cooling and stretching the fibers to enhance their tensile strength.

The resulting yarn is the foundation of the microfiber fabric, characterized by its ultra-fine and durable properties.

Weaving Techniques

Weaving microfiber fabric typically employs four lines of yarn, integrating both Fully Drawn Yarn (FDY) and Drawn Textured Yarn (DTY). These weaving techniques ensure that the microfiber fabric weaves closely woven, enhancing its durability and performance.

The integration of different yarns also contributes to the fabric’s unique texture, making it suitable for a variety of applications, from cleaning cloths to nylon upholstery and various weaves.

Splitting and Dyeing

The splitting process is essential in enhancing the absorbency of microfiber. This is achieved through an alkaline treatment that increases the fiber surface area, resulting in numerous small loops that improve cleaning capabilities and absorb water through a chemical process.

Dyeing is another crucial step, where the fabric obtains its characteristic colors and textures, contributing to its aesthetic appeal and versatility in various applications.

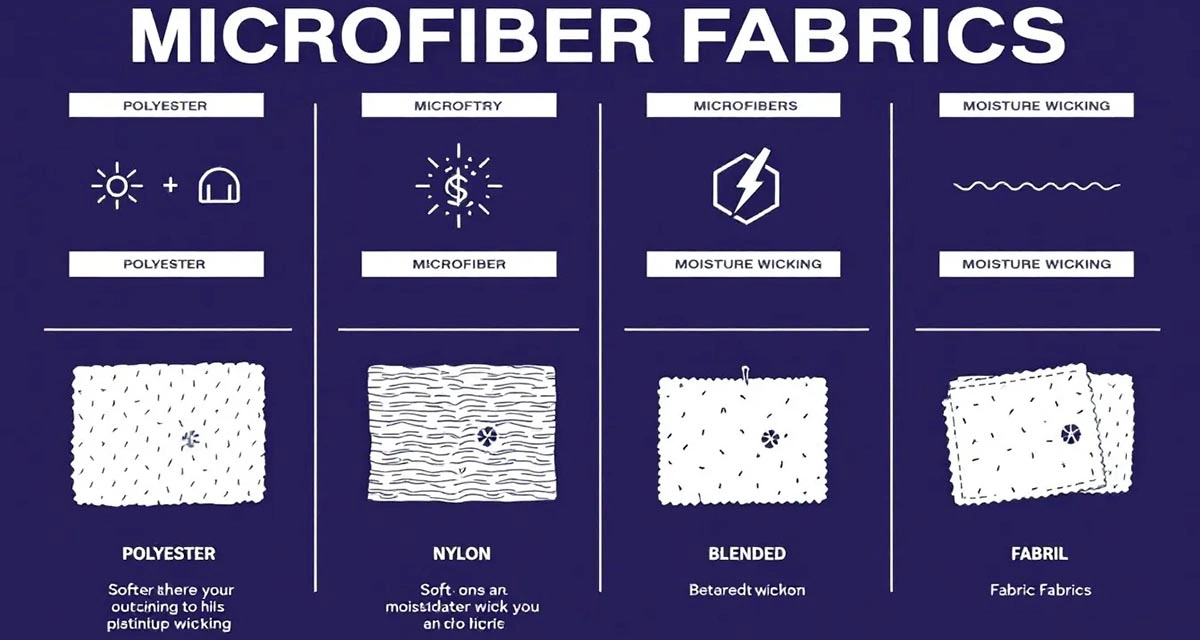

Types of Microfiber Fabrics

Microfiber fabrics come in different types, each with unique properties and applications. The most common types include:

-

Flat-weave

-

Split-weave

-

Ultrasuede

-

Terry microfiber

Each type offers distinct advantages, making microfiber a versatile material used in a wide range of household items such as cleaning cloths, athletic apparel, and upholstery. Additionally, microfiber is popular in accessories and sports equipment like wallets, backpacks, and shoes.

The strength, softness, water absorbency, and repellency of microfiber make it suitable for many uses. Flat-weave microfiber is recognized for its durability and is commonly used in garments and accessories, while split-weave microfiber, known for its waffle pattern, is ideal for glass cleaning due to its effective absorbency and cleaning properties that can repel water.

Specialized microfibers such as ultrasuede and terry microfiber cater to specific needs like faux leather applications and highly absorbent towels.

Flat-Weave Microfiber

Flat-weave microfiber is known for its durability and is commonly utilized in garments and accessories. This type of microfiber fabric is closely woven, providing a smooth and soft texture that makes it ideal for items like clothing and upholstery.

Its durability ensures that products made from flat-weave microfiber can withstand regular use and washing, making it a practical choice for everyday items.

Split-Weave Microfiber

Split-weave microfiber features:

-

A unique texture that clings to the skin, providing a different feel compared to flat-weave microfiber.

-

A waffle pattern that increases glide and reduces friction.

-

High effectiveness for cleaning applications such as glass cleaning.

In contrast, flat-weave microfiber is soft and smooth.

This type of microfiber towels’ enhanced absorbency and cleaning properties make it a favorite for tasks that require meticulous cleaning and drying.

Specialized Microfibers

Specialized microfibers are designed for specific functionalities and performance attributes. Micromodal is stretchier than polyester-polyamide microfiber. However, it is also less durable. Ultrasuede, a type of microfiber, competes with genuine suede leather and is used in garments and accessories, offering a synthetic alternative with similar aesthetic qualities.

Terry microfiber, known for its absorbent properties, is commonly used in towels, while Prolen, made of polypropylene, offers high or low elasticity and is softer than polyester-polyamide microfiber.

These specialized microfibers and other microfibers cater to diverse needs, from cleaning lenses to making high-performance athletic wear.

Uses of Microfiber Fabrics

Microfiber fabrics are incredibly versatile, finding applications in various sectors due to their unique properties:

-

In cleaning products, microfiber’s superior absorbency and ability to trap dirt make it ideal for items like washcloths, kitchen towels, and mop heads.

-

In home textiles, microfiber is used for upholstery, drapery, and bedding, providing durability and a soft feel.

-

In the apparel industry, microfiber’s moisture-wicking properties make it suitable for non-sports clothing and various accessories.

Proper care of microfiber can significantly extend its lifespan, with some items lasting beyond 300 washes if maintained correctly. This longevity, combined with microfiber’s electrostatic properties that enhance its use as a filtration material and insulation in construction, underscores its practicality and wide-ranging applications.

Cleaning Products

Microfiber is highly absorbent and has a soft texture, making it effective at cleaning without scratching surfaces. Its ability to pick up more dirt and grime than other cloth types enhances its cleaning capability. Microfiber cleaning cloths, with their electrostatic properties, are particularly good at absorbing grease and oil, making them indispensable in kitchens and cleaning products.

Designed to be strong and long-lasting, microfiber cleaning products leave no lint or dirt behind and dry quickly, making them both efficient and economical, even when dealing with dust.

Home Textiles

Microfiber is commonly used in home textiles such as:

-

Towels

-

Sheets

-

Pillowcases

-

Upholstery

-

Rugs

-

Throw blankets

Microfiber bed sheets, known for being breathable and lightweight, provide a comfortable sleep experience.

When washing microfiber bedding and linens, it is crucial to avoid drying on high temperatures or for extended periods to prevent damage. Proper care is essential to maintain the softness and durability of microfiber textiles.

Apparel and Accessories

Microfiber is desirable for apparel and accessories due to its softness, durability, and moisture-wicking properties. It wicks perspiration away from the body, making it an excellent choice for sportswear, including jerseys, t-shirts, shorts, and compression garments.

Additionally, microfiber is used for accessories such as belts, wallets, and handbags, often featuring a leather-like quality that appeals to both fashion and practicality.

Microfiber vs. Other Fabrics

Comparing microfiber with other fabrics like cotton and polyester reveals both similarities and differences that influence their respective applications:

-

Microfiber has a silk-like texture, offering superior comfort and breathability compared to polyester.

-

Polyester can feel scratchy and rough.

-

The choice between microfiber and other fabrics often depends on personal preferences and the intended use of the fabric.

Microfiber’s advantages in absorbency and durability make it a strong contender against cotton, which is known for its high breathability and temperature regulation. While polyester is derived from petroleum, microfiber can include polyamide, affecting its overall fabric durability and comfort. Factors such as comfort, breathability, and specific application needs play crucial roles in deciding which fabric is the best choice.

Microfiber vs. Cotton

Cotton is renowned for its high breathability, making it suitable for temperature regulation. However, microfiber’s moisture-wicking properties make it less prone to stain absorption compared to cotton. While microfiber has advantages in absorbency and durability, cotton generally offers greater breathability and resilience.

Microfiber sheets are known for their moisture-wicking, stain-resistant, and silky feel, although some drawbacks include static cling and heat retention. Additionally, microfiber is easier to care for, requiring less maintenance compared to cotton.

Microfiber vs. Polyester

Microfiber typically provides better comfort and breathability compared to polyester, which can lead to a cooler experience in warm conditions. While polyester is derived from petroleum, microfiber often includes polyamide, affecting its overall fabric durability and comfort.

When choosing between microfiber and polyester, it is essential to consider the specific needs for comfort and application, as microfiber offers superior breathability and a softer feel.

Environmental Impact of Microfiber

Microfibers are increasingly recognized as significant environmental contaminants, raising concerns about their long-term ecological effects. The process of washing microfiber textiles releases tiny plastic fibers that enter water systems, contributing to microplastic pollution. This plastic pollution impacts waterways and marine life, highlighting the need for more sustainable practices in microfiber production and usage.

Efforts to find eco-friendly alternatives are ongoing, with consumer sentiment towards microfiber fabric worsening due to its contribution to pollution. The negative environmental impact of microfiber, from production to disposal, underscores the importance of developing sustainable materials that can replicate microfiber’s benefits without the associated ecological harm.

Plastic Pollution

Microfiber textiles contribute to microplastic pollution, impacting waterways and marine life. The process of washing microfiber textiles releases tiny plastic fibers that enter water systems, exacerbating the problem of plastic pollution.

This environmental impact highlights the need for more sustainable practices in the textile industry to mitigate the adverse effects of microfiber.

Eco-Friendly Alternatives

Given the environmental impact of microfiber, there is a growing need for eco-friendly alternatives. Synthetic textiles and synthetic fiber contribute to plastic pollution at every stage of their lifecycle, from production to disposal.

Natural fibers, such as cotton, hemp, and bamboo, offer more sustainable options, although they may not match microfiber’s performance in all aspects. Consumer awareness about the environmental impact of microfiber has led to a demand for more sustainable cleaning products, textiles, and other fibers.

Innovations in textile technology continue to seek microfiber materials that can combine the benefits of microfiber with eco-friendly properties.

Caring for Microfiber Fabrics

Proper care for microfiber fabrics is essential to maintain their softness, absorbency, and durability. When washing microfiber fabrics, follow these guidelines:

-

Use cold or warm water with a mild detergent.

-

Avoid fabric softeners and bleach to prevent damage.

-

Wash microfiber items separately to avoid lint transfer from other fabrics.

These steps help ensure microfiber fabrics remain effective in their cleaning and absorbency capabilities.

For drying microfiber products, air drying is recommended to preserve the integrity of the fibers. If using a dryer, select a low heat setting to avoid damage and maintain the fabric’s performance; it should be dried immediately to ensure optimal results.

Storing microfiber fabrics in a cool, dry place is also important to prevent mildew and maintain their quality over time. By following these care instructions, microfiber products can provide long-lasting performance and maintain their unique properties.

Washing Instructions

To keep microfiber fabrics in optimal condition, use a mild detergent without additives like bleach or fabric softeners when washing. These additives can deteriorate the fibers, reducing their effectiveness.

Wash microfiber items separately to prevent lint from other fabrics from being trapped in the fibers, ensuring they remain clean and functional. This careful washing process helps maintain the fabric’s absorbency and durability.

Drying and Storage

To preserve the quality of microfiber fabrics:

-

Air drying is the best method.

-

If using a dryer, ensure it is set to a low heat setting to avoid damaging the fibers.

-

Store microfiber in a cool, dry place to prevent mildew and maintain the fabric’s durability.

Avoid tightly packing microfiber items to prevent crushing the fibers, which can affect their performance. Proper drying and storage practices ensure that microfiber products remain effective and long-lasting.

Summary

In summary, microfiber is a versatile and affordable synthetic fabric made from ultra-fine fibers that offer numerous benefits, including softness, high absorbency, and durability. Its applications range from cleaning products and home textiles to apparel and accessories. While microfiber outperforms many natural fibers in certain aspects, it also poses significant environmental challenges due to plastic pollution. Caring for microfiber properly can extend its lifespan and maintain its performance. As consumers and industries become more environmentally conscious, the search for sustainable alternatives to microfiber continues. Embracing these advances can help balance the benefits of microfiber with a commitment to environmental stewardship.

Frequently Asked Questions

What materials are used to make microfiber fabric?

Microfiber fabric is primarily made from a blend of polyester and polyamide, resulting in a durable and absorbent material ideal for various applications.

How is microfiber fabric different from cotton?

Microfiber fabric offers greater stain resistance and durability than cotton, while cotton is typically more breathable and resilient. Choosing between them depends on your specific needs for durability versus comfort.

What are the environmental concerns associated with microfiber?

Microfiber poses significant environmental concerns due to the release of tiny plastic fibers during washing, which contribute to plastic pollution and endanger aquatic ecosystems. Addressing this issue is crucial for protecting our waterways and marine life.

How should I care for microfiber fabrics?

To care for microfiber fabrics, wash them separately with a mild detergent and air dry or use a low heat setting in the dryer. Storing them in a cool, dry place ensures they remain in good condition.

Are there eco-friendly alternatives to microfiber?

Yes, natural fibers like cotton, hemp, and bamboo serve as eco-friendly alternatives to microfiber, although they may not provide the same level of performance.

Contact MH

MH offers microfiber fabrics. Please contact us for more details or inquiries. We're here to help!