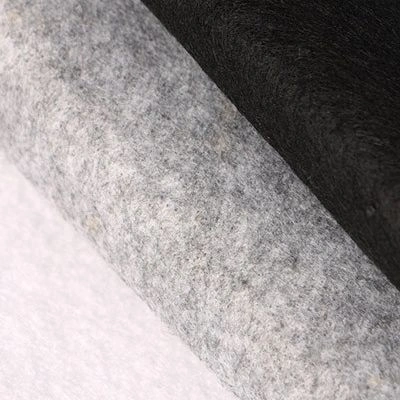

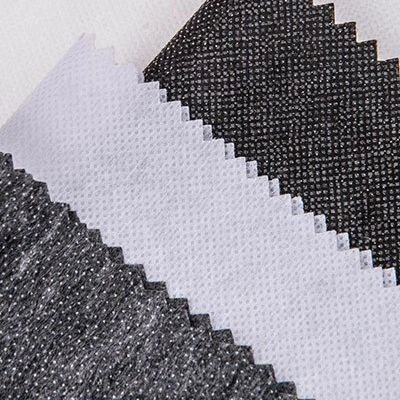

PP Needle Punch Non-woven Interlining Fabric

PP Needle Punch Non-woven Fabric

◆ Lead Time: 25-35 days

◆ Shipping: Sea freight, Railway freight

◆ Payment: T/T, L/C ...

MH Non-woven Interlining Factory

About Ningbo MH

MH specializes in garment accessories and fabrics, offering high-quality solutions for the textile and home décor industries. With advanced automated warehousing, MH ensures efficient supply chain management and provides comprehensive after-sales support, exclusively serving businesses, not individuals.

Product Details

PP (Polypropylene) needle-punched nonwoven fabric is a type of nonwoven material made from polypropylene fibers. Unlike traditional woven fabrics, it does not require spinning or weaving. Instead, the fibers are mechanically entangled through needle-punching to form a durable and functional fabric. This material is lightweight, breathable, and highly resistant to chemicals and moisture.

Features

- Lightweight and Durable: Polypropylene is a lightweight material, and the needle-punching process enhances its durability.

- Moisture Resistance: PP fibers are hydrophobic, making the fabric resistant to water and moisture.

- Chemical Resistance: Excellent resistance to acids, alkalis, and other chemicals.

- Breathable and Permeable: The fabric allows air and water vapor to pass through, making it suitable for filtration and insulation applications.

- Eco-Friendly: Polypropylene is recyclable and can be reused, contributing to environmental sustainability.

- Customizable Properties: The thickness, density, and surface texture can be adjusted to meet specific application requirements.

Usage

- Geotextiles: Used in civil engineering projects for soil stabilization, drainage, and erosion control.

Acts as a separation layer in road construction and landscaping. - Filtration: Air and liquid filtration media in industrial and environmental applications.

- Automotive Industry: Interior components such as carpets, seat covers, and soundproofing materials.

- Home Textiles: Mattress padding, furniture linings, and carpet underlays.

- Agriculture: Ground covers, weed control fabrics, and crop protection materials.

- Medical and Hygiene Products: Disposable surgical gowns, masks, and other protective materials.

- Packaging: Protective layers for fragile goods and reusable shopping bags.