Mastering Zipper Sizing: How to Size a Zipper Accurately

When you need the perfect zipper for your project, knowing how to size a zipper is essential. This guide will show you how to measure the width of the zipper teeth and the length of the zipper, helping you select the right size for your specific needs.

Key Takeaways

-

Zipper sizing is crucial; it is determined by the width of the closed teeth in millimeters, affecting both function and aesthetics.

-

Accurate measurement of zipper length and gauge is essential for selecting the right zipper for various applications, ensuring optimal fit and performance.

-

Specialty zippers, including invisible and waterproof options, enhance project usability and aesthetic appeal, catering to specific needs and conditions.

Understanding Zipper Sizes

Zipper sizing is not just a trivial detail; it’s the backbone of ensurin g the right fit and function for a wide array of projects. Key points about zipper sizing include:

g the right fit and function for a wide array of projects. Key points about zipper sizing include:

-

The size of a zipper is determined by the width of its closed teeth in millimeters.

-

This size significantly affects the zipper’s effectiveness and aesthetics.

-

Accurate measurements of both the length and gauge are crucial.

-

These measurements are essential for selecting the perfect zipper for your needs.

When selecting zipper sizes, consider the specific application. Are you working on a delicate dress or a sturdy tent? The width of the zipper teeth will inform you whether it’s suitable for lightweight fabrics or heavy-duty applications.

Accurate understanding and measurement of zipper sizes ensure your projects look good and function flawlessly at their actual size.

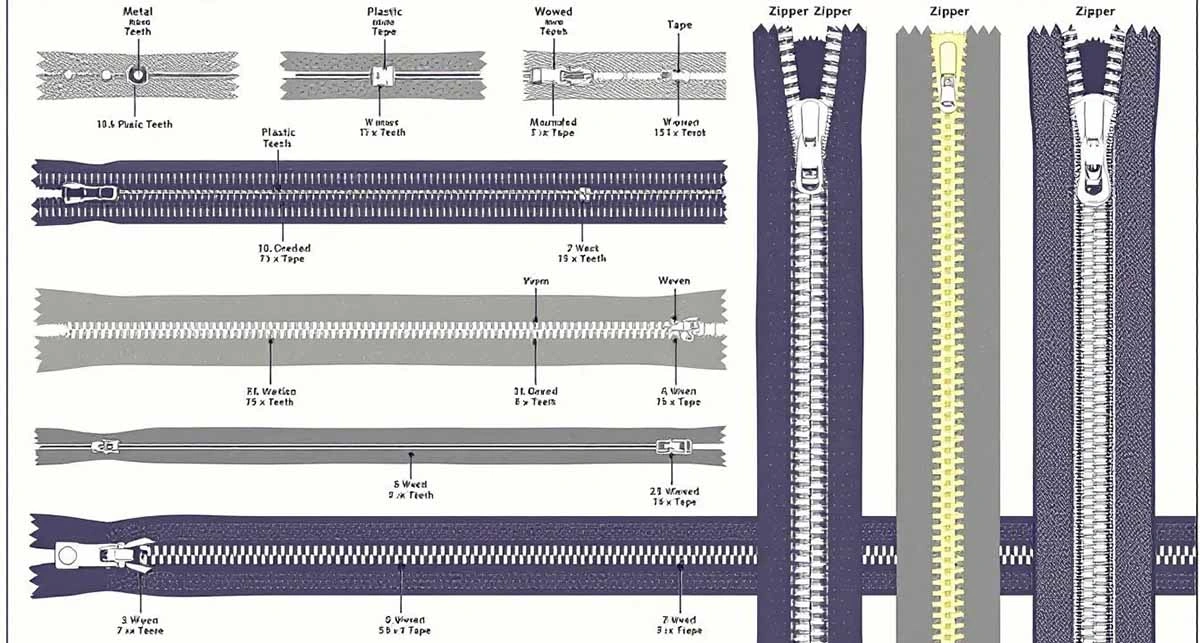

What is a Zipper Gauge?

Though it may confuse beginners, zipper gauge is simple to understand. The gauge refers to the width of the closed zipper teeth in millimeters. For instance, if they measure 5 millimeters, the zipper is a #5 gauge. This number helps in selecting the right zipper for your project.

The larger the gauge number, the thicker and more robust the zipper. Key points about zipper gauges include:

-

Higher gauge numbers like #10 are used for heavy-duty applications.

-

Smaller gauges like #3 suit lightweight fabrics and delicate projects.

-

Knowing the gauge helps match the zipper size to your project’s specific requirements, ensuring durability and ease of use.

Common Zipper Sizes

Common zipper sizes include #2 and #3, which are often used for lightweight projects such as dresses, home decor, and small bags. These smaller zippers are flexible and less obtrusive, making them perfect for formal wear and delicate materials, regardless of the zipper’s size.

Knowing the typical applications of these common different sizes can save you time and ensure you always have the right zipper on hand for your projects.

Measuring Zipper Size

Accurate zipper size measurement is crucial for the right fit and function. The size of a zipper is represented by the width of its teeth in millimeters. There are two key measurements to consider: the length and the gauge of the zipper. To measure zipper size, measuring tapes, rulers, and digital calipers are essential tools for this task.

To measure the gauge, check the horizontal width of the teeth when closed. For broken zippers, measure one side and double the measurement, rounding slightly if needed. This method ensures an accurate size for replacement or repair.

Using a Ruler or Caliper

To measure the width of the zipper teeth:

-

Ensure the zipper is fully closed.

-

Use a ruler or a digital caliper for precise measurement.

-

Take the measurement in millimeters.

-

Ensure the zipper is fully closed for the most reliable results.

Precision in measurement ensures selecting the correct size zipper for a perfect fit.

Identifying Slider Markings

Check the back of the slider for the size code, which may appear as a number (e.g., #5) or a number-letter combination.

For specific types like Vislon zippers, the size is indicated by a code on the back of the zipper slider. Reading these markings helps you quickly find the right slider for your zipper.

Determining Zipper Length

Determining the length of a zipper varies depending on the type of zipper you are working with. Zipper lengths are typically measured from the top stop to the bottom stop for closed-end designs. This measurement excludes the tape without the chain, ensuring you get the actual working length of the zipper.

Different types of zippers require different measurement techniques. For instance, one-way separating zippers are measured from the top of the top stop to the bottom of the retainer box, while two-way zippers are measured from the top of one top stop to the bottom of the reinforcement tape.

Accurate measurement ensures the zipper fits perfectly in its intended application.

Closed-End Zippers

To measure a closed-end zipper, start at the top stop and measure down to the bottom stop. This straightforward method ensures you get the exact length needed for your project.

Accurate measurement ensures a proper fit and functionality for purses, backpacks, or any item needing a closed-end zipper.

Separating Zippers

For separating zippers, the measurement is taken from the top of the top stop down to the bottom of the retainer box. This method ensures you measure the entire functional length of the zipper, which is crucial for garments like jackets and coats where the zipper needs to separate completely.

Accurate measurement ensures your project functions as intended.

Two-Way Zippers

Measuring two-way separating zippers involves measuring from the top of one top stop to the bottom of the zipper tape. For two-way bag-style closed-end zippers, measure from the top of one bottom stop to the bottom of the other.

This method ensures the accurate length for items like bags and jackets that need access at both ends.

Choosing the Right Zipper for Your Project

When selecting a zipper, consider the following:

-

The fabric type and the intended use.

-

Different zippers are designed to perform under specific conditions, such as in a delicate dress or a rugged backpack.

-

Specialty zippers are crafted to enhance usability in unique applications, from fashion to industrial use.

-

Expert guidance helps in measuring and selecting zipper sizes based on the application, ensuring the right fit for various items.

Recognizing the fabric type is important:

-

Lightweight fabrics require zippers with smaller teeth sizes, like #2 or #3, which offer flexibility and seamless integration.

-

Medium-weight fabrics such as jeans and jackets benefit from sturdier zippers, typically around size #4.5.

-

For heavy-duty applications, zippers in the range of #7 to #10 are ideal, providing the strength and durability needed for outdoor gear and luggage.

Choosing the right zipper ensures both functionality and the aesthetic appeal of your creations. Understanding the unique requirements of each project can significantly impact the outcome.

Lightweight Fabrics

For lightweight fabrics, molded tooth, coils, and metal zippers with smaller metal teeth sizes, like #2 and #3, are preferable. These three main types of zippers offer the flexibility needed to pull for delicate projects such as dresses, skirts, and smaller bags like clutches or handbags, including those made with nylon coil.

Their subtle presence keeps the focus on the fabric and design.

Medium-Weight Fabrics

Medium-weight fabrics, such as those used in jeans and jackets, require zippers that are both durable and functional. The best zipper size for these applications is typically #4.5, which offers the right balance of strength and flexibility.

These zippers ensure your medium-weight garments and pants withstand everyday use while maintaining functionality.

Heavy-Duty Applications

For heavy-duty applications, zippers sized #7 to #10 are generally recommended to ensure longevity and durability. These zippers are designed to handle increased stress and harsh conditions, making them ideal for use in outdoor gear and luggage.

Choosing the right zipper for heavy-duty use enhances your projects’ performance and longevity, and may sometimes require a zipper replacement.

Specialty Zippers

Specialty zippers are designed for specific functions and materials, enhancing their usability in unique applications. MH provides a wide variety of zipper types, including nylon, metal, and plastic options. Medium-weight bag zippers are commonly used for handbags, backpacks, totes, and luggage, while heavy-weight non-separating zippers are suitable for boots, outdoor textiles, large bags, and upholstery. Understanding your project’s specific needs helps in choosing the main types of specialty zippers.

Zippers sized #7-#10 are often used for larger projects, including outdoor gear and heavy clothing. These zippers are crafted to withstand the rigors of demanding environments, ensuring that your projects remain functional and durable. Selecting the appropriate specialty zipper enhances both functionality and aesthetic appeal.

Invisible Zippers

Invisible zippers are designed to be concealed within seams, making them ideal for formal garments where a seamless appearance is desired. These zippers blend seamlessly into the fabric, making them perfect for sophisticated clothing like evening gowns and formal dresses that sew beautifully, showcasing the art of sewing.

Their discreet closure keeps the focus on the garment’s design and elegance.

Waterproof Zippers

Waterproof zippers are essential for outdoor gear, as they prevent water entry and maintain the integrity of items like tents and jackets. Constructed with materials that resist water, these zippers are ideal for outdoor gear and marine applications.

Waterproof zippers protect your equipment from water damage, ensuring functionality in wet conditions.

Two-Way Separating Zippers

Two-way separating zippers allow for flexible access from one end, making them particularly useful in jackets and bags. This type of zipper provides the convenience of opening from either end, enhancing usability for items that require frequent access.

Incorporating two-way separating zippers into your projects offers enhanced functionality and versatility.

MH's Expertise in Zippers

MH is recognized as a top supplier of superior zippers worldwide, serving a variety of industries. With over 20 years of experience, MH is globally trusted for accurate sizing, consistent quality, and reliable zipper solutions. MH offers an extensive range of metal, nylon, and plastic zippers in various sizes, colors, and styles, catering to garment factories, bag manufacturers, and wholesalers worldwide.

MH’s expertise extends beyond just supplying zippers. The company offers guidance on measuring and selecting zipper sizes for specific applications like clothing, luggage, tents, shoes, and outdoor equipment. Leveraging MH’s knowledge ensures you select the right zipper for your project, enhancing its functionality and longevity.

Customization Options

MH offers a wide range of customization options to meet specific project requirements, including:

-

Tailored zipper lengths

-

Customization in various colors, including an extensive range of 600 shades

-

Zipper teeth color customization to align with design specifications

MH also offers OEM/ODM customization for zipper size, slider type, and tape color, ensuring you get the exact product needed.

Global Reach and Reliability

MH serves clients in over 150 countries as a B2B manufacturer and exporter. The company ensures fast international delivery and professional export service, maintaining a high level of reliability.

With 9 factories and over 3,000 employees, MH meets bulk supply needs efficiently at factory-direct prices. For consistency, quality, and reliability in zippers, MH is your best bet.

Summary

Mastering zipper sizing is an essential skill for anyone involved in sewing and crafting. Understanding zipper gauge and length, how to accurately measure zippers, and choosing the right type for your project are all crucial steps in ensuring the success of your creations. By paying attention to these details, you can avoid common issues such as broken zippers and ensure your projects are both functional and aesthetically pleasing.

Whether you are working with lightweight fabrics, medium-weight garments, or heavy-duty applications, selecting the right zipper can make all the difference. With MH’s extensive range of zippers and expert guidance, you can confidently tackle any project, knowing you have the best tools at your disposal. Keep these tips in mind, and you’ll be well on your way to mastering zipper sizing and creating high-quality, durable projects that stand the test of time.