Essential Guide to Interfacing in Sewing Projects

Interfacing is a crucial material in sewing that adds structure and support to fabrics, ensuring they hold their shape and form. Whether you’re crafting garments, bags, or home textiles, understanding and using the right interfacing can elevate the quality of your projects. In this guide, we’ll explore the different types of interfacing and how to choose the best one for your needs.

Key Takeaways

-

Interfacing is essential for providing structure and stability in sewing projects, enhancing the professional finish of garments, bags, and home textiles.

-

There are two main types of interfacing—fusible and sew-in—with specific applications; fusible interfacing is ideal for easy application, while sew-in interfacing is preferred for delicate fabrics.

-

Choosing the right interfacing involves considering fabric type, weight, and project requirements to ensure optimal support and maintain the garment’s intended shape.

Understanding Interfacing and Its Uses

Interfacing provides structure and stability in garments, bags, and textiles, acting as a backbone that ensures your projects maintain their intended shape and support. Imagine a crisp collar, a sturdy bag, or a perfectly structured dress; all these are often achieved with the help of interfacing. Its main purpose is to stabilize fabrics by providing support, making it particularly important in areas such as collars, cuffs, and button plackets.

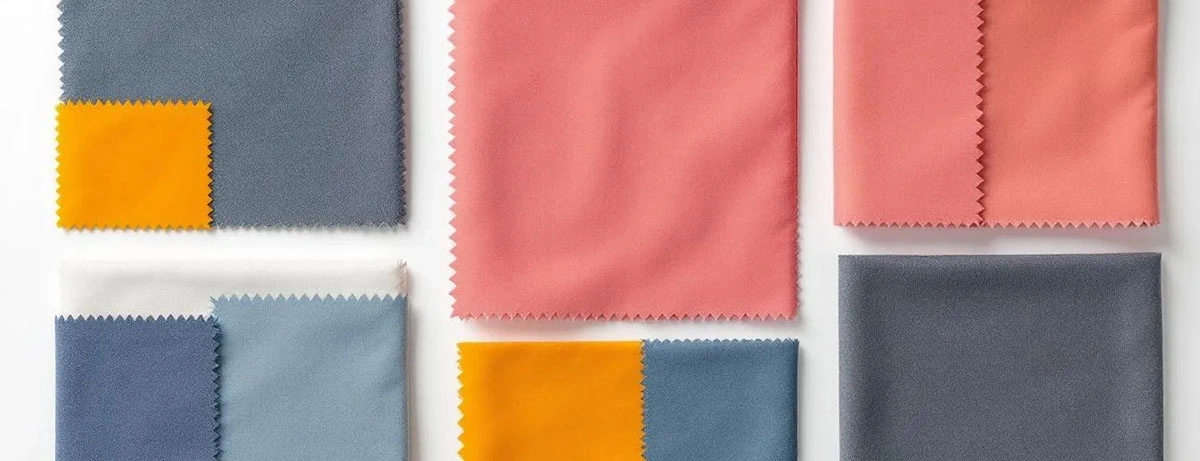

When choosing interfacing, it’s essential to consider the colours and weight. Using dark interfacing on light fabrics can show through and be noticeable, so matching the darkness of the interfacing with the shade of the fabric is crucial for a consistent look. Interfacings usually feature dark shades such as black and charcoal. They also come in lighter shades, including white and cream. While not mandatory in all sewing projects, interfacing is highly recommended for enhancing structure and ensuring your creations hold up over time.

From bags and home textiles to complex garments, interfacing is the key to achieving a professional finish. Whether you’re working on a casual shirt or a tailored suit, understanding how to use interfacing can transform your sewing projects from amateur to expert.

We’ll explore the different types of interfacing and how to choose the right one for your specific needs.

Types of Interfacing: An Overview

Interfacing comes in various types, each designed to cater to different sewing needs. The two primary types of interfacing are fusible and sew-in. Fusible interfacing has adhesive properties that bond with fabric using heat, while sew-in interfacing is stitched onto the fabric. These two main types serve as the foundation for more specialized interfacing, such as woven, non-woven, and knit interfacing, each offering unique benefits and applications.

Fusible interfacing is known for its quick and easy application, making it a popular choice for many projects. Sew-in interfacing, on the other hand, is ideal for delicate and specialty fabrics that can be damaged by heat.

Different types of interfacing and their characteristics:

-

Non-woven interfacing: versatile and user-friendly

-

Woven interfacing: requires careful grain matching

-

Knit interfacing: perfect for stretch fabrics, providing the necessary flexibility without restricting movement

Each of the three main types of tools has specific uses and value that we’ll explore in detail.

Fusible Interfacing: Quick and Easy Application

Fusible interfacing is a favorite among many sewists due to its ease of use and reliable results. This type of interfacing is applied using heat and steam, bonding it permanently to the fabric. The main advantage of fusible interfacing is that it provides a fast and firm bond, making it especially beneficial for structured items like collars, cuffs, and waistbands. It’s suitable for a variety of fabrics, including cotton, linen, and polyester.

When using fusible interfacing, the process involves activating the adhesive with heat and moderate pressure. MH provides a range of woven, non-woven, and knitted interfacings that are widely used in apparel, uniforms, and home textiles. This versatility makes fusible interfacing a go-to choice for many sewing projects, offering both convenience and professional results.

Sew-In Interfacing: For Delicate and Specialty Fabrics

For delicate and specialty fabrics, sew-in interfacing is the recommended choice. Unlike fusible interfacing, sew-in interfacing does not use heat, making it ideal for fabrics that can be damaged by high temperatures. This type of interfacing allows fabrics to retain their original feel and drape, which is particularly important for lightweight and medium-weight fabrics.

Applying sew-in interfacing involves meticulous stitching to ensure it stays in place and preserves the fabric’s drape. This method is often used in high-quality garments where maintaining the fabric’s natural texture and appearance is crucial, especially when it is sewn properly.

Whether you’re working with delicate silks or specialty fashion fabrics, sew-in interfacing provides the necessary support without compromising the fabric’s integrity.

Woven Interfacing: Perfect for Tailored Garments

Woven interfacing is made from woven fibres, designed to interact seamlessly with fabrics. Key characteristics and uses include:

-

Perfect for tailored garments, providing structure and support while maintaining the fabric’s natural drape.

-

Often used to eliminate stretch in fabrics.

-

Particularly useful when installing zippers in knit fabrics.

One of the key benefits of woven interfacing is that:

-

It mimics the grain of the fabric, preserving its handle and drape compared to other interfacing types.

-

It’s well-suited for medium-weight fabrics like cotton and linen.

-

It is an excellent choice for shirts, dresses, and tailored clothing.

Whether you’re crafting a structured blazer or a crisp collar, woven interfacing ensures your garments look polished and professional.

Non-Woven Interfacing: Versatile and User-Friendly

Non-woven interfacing is made from bonded fibers, providing a stable yet flexible material for sewing. Key features include:

-

It lacks a directional grain line, making it easy to cut in any direction.

-

Its flexibility allows it to adapt to a variety of shapes and designs without distortion.

-

It is an incredibly versatile option for sewing projects.

Medium-weight non-woven interfacing is best suited for common fabrics like cotton and linen, making it ideal for crafting shirts, dresses, and household items. Its versatility and ease of use make it a favorite among sewists, particularly for projects that require a stable yet flexible support layer of fashion fabric.

Whether you’re making garments, accessories, or home textiles, non-woven interfacing is a reliable choice.

Knit Interfacing: For Stretch Fabrics

Knit interfacing is specifically designed for stretchy fabrics, providing the necessary flexibility without restricting movement. This type of interfacing maintains the stretch of the fabric, making it ideal for garments that need to move with the body, such as activewear and knit dresses. Good elasticity and wash resistance are characteristics of MH’s interfacing products, ensuring your projects remain durable and functional.

When working with knit fabrics, choosing the right type of interfacing is crucial to maintaining the fabric’s natural properties. Knit interfacing offers the perfect balance of support and flexibility, allowing you to create garments that are both comfortable and stylish. Whether you’re sewing a stretch dress or a pair of leggings, knit interfacing ensures your projects are both functional and fashionable.

How to Choose the Right Interfacing for Your Project

Choosing the correct interfacing type is essential, as it influences the garment’s overall structure and appearance. Consider the following when selecting interfacing:

-

There are three primary kinds of interfacing: woven, non-woven, and knit, each serving distinct purposes.

-

Take into account the fabric type, weight, and project requirements.

-

Avoid using heavier interfacing than the fabric, as it can dominate the garment and add unnatural structure.

-

Match your interfacing weight to that of the fabric to ensure proper balance.

In the following subsections, we’ll explore:

-

How to match interfacing weight to fabric weight

-

How to consider fabric type and compatibility

-

How to evaluate project requirements to ensure you choose the right interfacing for your specific needs

By understanding these key factors, you’ll be able to select interfacing that enhances the quality and longevity of your sewing projects.

Matching Interfacing Weight to Fabric Weight

When selecting interfacing weight, consider the following:

-

It should generally match or be lighter than the fabric to avoid overpowering the garment’s structure.

-

Choosing interfacing with a similar or lighter weight than the fabric is crucial to avoid stiffness and maintain the desired drape.

-

The weight range of MH’s interfacings is from 20gsm to 200gsm, offering options for a variety of fabric weights and project needs.

Balancing the interfacing weight with the fabric weight helps maintain the garment’s intended shape and ensures a professional finish. For instance, medium-weight fabrics like cotton and linen pair well with medium-weight interfacing, providing the right amount of support without adding unnecessary bulk.

By carefully matching the weight of your interfacing to your fabric pattern, you can achieve a harmonious balance that enhances the overall look and feel of your project.

Considering Fabric Type and Compatibility

Understanding your fabric’s characteristics and project needs is crucial for selecting the right interfacing type. Knit fabrics, for example, require interfacing that can move with the material to maintain flexibility. When working with delicate or lightweight fabrics, it’s important to set the iron to the appropriate heat level to prevent damage during bonding.

Using a pressing cloth between the iron and interfacing can protect both the fabric and the interfacing from direct heat, ensuring a smooth and wrinkle-free application. By considering the fabric type and ensuring compatibility, you can select interfacing that not only supports your project but also enhances its overall quality and appearance.

Whether you’re working with medium-weight fabrics, lightweight fabrics, or stretch fabrics, choosing the right interfacing ensures your projects look and feel professional.

Evaluating Project Requirements

The intended function and design of a project dictate the necessary firmness and support from interfacing. For example, tailored garments often require interfacing that reduces stretch, providing a clean and structured finish. Thoughtful interfacing selection enhances quality and longevity, leading to a professional-looking product.

Evaluating your project’s requirements involves considering the desired outcome, the fabric type, and the specific areas that need support. By carefully Review these factors, you can select interfacing that meets the needs of your project and ensures a successful final product.

Whether you’re creating a structured blazer or a delicate dress, the right interfacing can make all the difference in achieving a polished and professional finish.

Applying Fusible Interfacing Correctly

Applying fusible interfacing involves:

-

Preparation and technique to ensure a strong bond and a professional finish.

-

Using heat and steam to bond with fabric permanently.

-

Glue dots on the back of the interfacing that activate with heat.

-

Using the right heat settings to ensure a strong bond without damaging the fabric.

In the following subsections, we’ll explore how to prepare your fabric and interfacing, as well as techniques and tips for bonding with heat. By following these steps, you can achieve a smooth and wrinkle-free application, ensuring your projects look and feel professional.

Preparing Your Fabric and Interfacing

Before applying fusible interfacing, it’s important to prepare both your fabric and interfacing properly. Start by using a scrap piece of fabric to check the interfacing weight and shaping. The adhesive side of the interfacing has a slightly bobbly, raised appearance and is shiny.

When cutting interfacing, use a rotary cutter or scissors, cutting larger pieces first for efficiency. Position the interfacing accurately on your fabric, ensuring the adhesive side is facing the wrong side of the fabric. This preparation step is crucial for achieving a smooth and even bond.

Bonding with Heat: Techniques and Tips

Bonding fusible interfacing with heat involves a few key techniques to ensure a smooth and wrinkle-free application:

-

Set your iron to the appropriate heat level for your fabric type.

-

Use a pressing cloth to protect both the fabric and interfacing.

-

Place the interfacing adhesive side down on the wrong side of the fabric.

-

Cover with the pressing cloth.

Apply the hot iron with consistent heat and moderate pressure, focusing on one section at a time to ensure even adhesion. Avoid moving the iron back and forth, as this can cause wrinkles and uneven bonding. Instead, use a pressing motion, holding the iron in place for a few seconds before moving to the next section.

This technique ensures a strong bond and a professional finish for your sewing projects.

Common Interfacing Applications in Garment Construction

Interfacing is an essential component in garment construction, providing support and structure in specific areas such as:

-

Collars, which need to be crisp and firm

-

Cuffs, which also require crispness and firmness

-

Waistbands, which benefit from added stability

-

Plackets, which require additional reinforcement

These areas often experience high stress and need extra support to maintain their focus, shape, search, and materials layers durability on the right side while managing tasks. This is a test of their resilience.

Different types of interfacing, such as woven and non-woven, are selected based on the specific requirements of each garment area. For instance, heavyweight interfacing can provide extra stiffness for collars and cuffs, while lightweight options offer subtle support for more delicate areas. MH offers a range of interfacings designed to provide reliable structure and support while maintaining softness and comfort.

Using interfacing can also ensure that design elements like facings and pocket flaps maintain their intended structure. By choosing the right type and weight of interfacing, you can enhance the overall quality and longevity of your garments, ensuring they look polished and professional.

Interfacing for Bags and Accessories

Interfacing is crucial in bag making to enhance the structure and stability of the fabric. Whether you’re making a sleek handbag or a sturdy tote, the right interfacing can provide the necessary firmness and support to achieve the desired look and functionality. Both fusible and sew-in interfacing options are available, catering to various bag construction needs.

Choosing the appropriate interfacing weight is essential for achieving the desired firmness and support in bags. For instance, medium-weight interfacing can add body to bag linings while also enhancing durability. MH’s interfacings can reinforce bags and hats, providing a professional finish and ensuring your accessories remain functional and stylish.

Wholesale Order

MH is a professional wholesale supplier of garment accessories and fabrics from China for those looking to purchase interfacing in bulk. MH focuses on wholesale only, not retail, and is known for reliability, consistent quality, and long-term partnerships in the global market. This makes MH an excellent choice for garment manufacturers and large-scale sewing projects.

MH offers an extensive range of products, including woven, non-woven, and knitted interfacings, with options for custom width, color, and coating type. With competitive pricing and strict quality control, MH ensures that you receive high-quality interfacing that meets your project needs.

By partnering with MH, you can access a reliable supply of interfacing to support your sewing endeavors.

Summary

In summary, interfacing is a vital component in sewing projects, providing essential structure and support to garments, bags, and accessories. By understanding the different types of interfacing and how to choose the right one for your project, you can achieve professional results and enhance the quality and longevity of your creations. Whether you’re working with fusible, sew-in, woven, non-woven, or knit interfacing, each type offers unique benefits and applications to suit your specific needs.

From preparing your fabric and interfacing to applying it correctly and maintaining your finished projects, this guide has covered all the essential aspects of interfacing. We hope this comprehensive guide has equipped you with the knowledge and confidence to elevate your sewing projects. Happy sewing!

Frequently Asked Questions

What is the main purpose of interfacing in sewing projects?

The main purpose of interfacing in sewing projects is to stabilize fabrics, providing necessary support to maintain the intended shape and structure of garments. This ensures that your creations have the durability and form expected in quality clothing.

How do I choose the right interfacing for my project?

To choose the right interfacing, match its weight and type to that of your fabric while considering the specific requirements of your project. This ensures compatibility and enhances the final outcome.

What are the different types of interfacing available?

The primary types of interfacing include fusible, sew-in, woven, non-woven, and knit, each designed for specific applications and providing distinct advantages. Understanding these options allows for better selection based on project needs.

How do I apply fusible interfacing correctly?

To correctly apply fusible interfacing, place the adhesive side down on the wrong side of the fabric and press with a hot iron using a pressing cloth to ensure even heat and pressure for proper bonding. This method will secure the interfacing effectively.

How should I care for interfaced projects?

To care for interfaced projects effectively, pre-shrink woven interfacings, wash sew-in interfacing like regular fabric, and hang dry it flat to maintain shape and prevent wrinkles. This approach ensures your projects look their best and remain durable.