Parts of Zipper: What Are They Called?

Zippers are everywhere—from the clothes we wear to the bags we carry and even the cushions on our sofas. Despite their ubiquity, most of us probably don’t give much thought to how zippers work or what they’re made of. If you’re in the manufacturing industry, though, understanding the components of a zipper is essential for selecting the right type for your products. Being familiar with zipper parts and zipper components is key to ensuring the right fit and function for your needs.

This blog will take you through the anatomy of a zipper, explain how each part works, and offer some tips for zipper maintenance. Whether you’re a clothing wholesaler, home textile manufacturer, or bag producer, this article will help you better understand the small but mighty closure that contributes to so many products—zippers are among the most common closures used in garments and accessories.

Introduction to Zippers

Zippers are an essential closure mechanism found in countless sewing projects, from everyday garments like jackets and pants to bags, cushions, and home decor. Whether you’re a beginner learning to sew or an experienced manufacturer, understanding the basics of zippers and their components is key to achieving a professional finish in your creations.

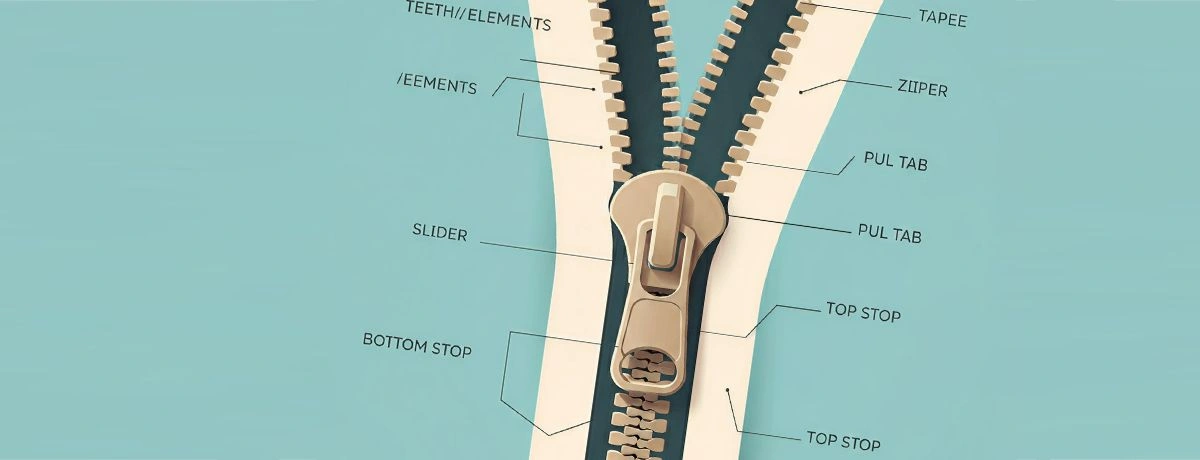

At the heart of every zipper are several main components: the zipper tape, zipper teeth, and zipper slider. The zipper tape is the fabric strip that is sewn into your project, providing a sturdy base for the zipper teeth. Zipper teeth—made from materials such as metal, plastic, or nylon coil—are the interlocking elements that allow the zipper to open and close smoothly. The zipper slider is the mechanism that glides along the teeth, joining or separating them as you pull the zipper open or shut.

There are different types of zippers designed for specific uses. Separating zippers, for example, are commonly used in coats and jackets, allowing the two sides of the garment to fully separate when unzipped. Non-separating zippers, on the other hand, remain joined at the bottom, making them ideal for pants, skirts, and bags. Metal zippers, known for their durability and classic look, are often chosen for jeans, boots, and heavy-duty bags, while coil zippers—featuring a flexible nylon coil—are popular in lightweight garments and cushions.

Each zipper includes additional components that contribute to its function and ease of use. The zipper pull, or pull tab, is attached to the slider and makes it easy to open and close the zipper. For separating zippers, the insertion pin and starter box are crucial: the insertion pin is inserted into the starter box to align the zipper teeth before pulling the slider up. Top stops and bottom stops are small pieces at each end of the zipper tape that prevent the slider from coming off the track, ensuring the zipper stays securely attached to your fabric.

When it comes to installing zippers, having the right tools can make all the difference. A zipper foot is a specialized sewing machine attachment that allows you to sew close to the zipper teeth for a neat finish. For more precise installation, a zipper jig can help guide the zipper and keep it straight as you sew.

Understanding the structure and function of all the parts of a zipper—whether it’s a metal zipper with sturdy metal teeth, a coil zipper with a flexible nylon coil, or a molded tooth zipper for bags and cushions—empowers you to choose the perfect match for your project. With the right knowledge and tools, you can confidently install zippers in a variety of styles and materials, ensuring your finished products are both functional and stylish.

A Brief History of the Zipper

The zipper, as we know it today, has undergone significant evolution. The first zipper-like fastening device was patented in 1851 by Elias Howe, best known as the inventor of the sewing machine. However, his design was not practical, and it wasn’t until 1893 that Whitcomb L. Judson created the “clasp locker,” a predecessor to the modern zipper. Judson’s invention provided the base for Gideon Sundback to create the first practical zipper in 1913. Sundback’s design improved strength, durability, and functionality, setting the stage for widespread adoption.

Since then, zippers have become an essential part of clothing, accessories, and upholstery. Over time, different styles of zippers, such as old style and new style designs, have emerged to suit various applications and reflect advancements in zipper technology. Understanding their components is key to leveraging their benefits in your manufacturing operations.

The Parts of a Zipper

There are three main types of zippers commonly used in manufacturing: coil, stamped plastic, and stamped metal. These main types can be identified by their distinct features and are suited for different uses, such as in apparel, bags, and home decor, depending on whether they are separating or non-separating zippers.

While zippers may seem straightforward, they’re actually made up of several carefully designed parts, each serving a specific function. Here’s a detailed look:

-

Zipper sliders: The zipper slider is the component that moves up and down the zipper teeth, opening or closing the zipper. The slider slides along the teeth, creating the zip and ensuring the zipper is closed.

-

Teeth: These are the interlocking pieces that the slider brings together or separates to open or close the zipper. The movement of the slider along the teeth forms the zip and keeps the zipper closed.

-

Top stop: This prevents the slider from coming off the top of the zipper.

-

Bottom stop: This prevents the slider from coming off the bottom of the zipper.

-

Top tape extension: This is the extra fabric extending past the top stop, reinforcing the zipper and aiding in assembly.

-

Bottom tape extension: This is the portion of the zipper tape that extends beyond the bottom stop or retainer box, providing durability and ensuring proper attachment at the end of the zipper.

-

Starter box or retainer box: Located on one side of the zipper tape at the bottom, just below the teeth, this component helps align the zipper parts and is essential for separating zippers.

Understanding these zipper components helps in identifying the main types and their different uses, ensuring you select the right zipper for your project.

1. Tape

The tape is the fabric that serves as the base of the zipper. It is sewn into the garment, bag, or other product. Typically made of polyester, cotton, or nylon, the zipper tape provides flexibility and durability.

-

Function: Holds the teeth or elements in place and connects them to the main fabric.

-

Consideration: Choose a tape that matches the weight and material of your product. For heavy-duty items, reinforced tape is best.

At each end of the zipper tape, you will find the top tape extension and bottom tape extension. The top tape extension is the extra fabric that extends past the top stop, reinforcing the zipper and helping with assembly. The bottom tape extension is the portion of tape beyond the bottom stop or retainer box, providing durability and ensuring secure attachment at the zipper's end.

2. Teeth/Elements

The teeth (or elements) are the interlocking parts of the zipper that connect to form a closure. These are typically made of metal, plastic, or coil (a string-like plastic).

-

Metal Teeth: Strong and durable, often used for jeans or boots.

-

Molded Plastic Teeth: Lightweight, corrosion-resistant, ideal for bags and sportswear.

-

Coil Teeth: Flexible, smooth, and commonly used in lightweight garments and upholstery.

Function: The teeth interlock to create a secure connection and provide the zipper’s primary closing mechanism. When the slider moves, it brings the teeth together, producing the characteristic 'zip' sound and ensuring the zipper is fully closed. Tooth size and spacing can vary depending on the intended application.

3. Slider

The slider, also known as the zipper slider, is the moving part of the zipper that joins or separates the teeth. Zipper sliders are most often made of metal or durable plastic, with various finishes available to suit aesthetic requirements.

-

Function: The slider slides up or down the teeth to close or open the zipper.

-

Types:

-

Automatic Lock Slider: Locks in place to prevent unintentional movement, ideal for apparel.

-

Non-Locking Slider: Freely moves without locking, often used in luggage or low-tension applications.

-

Reversible Slider: Useful for reversible clothing or bags.

4. Pull Tab

The pull tab is the part attached to the slider that allows easy operation of the zipper. Pull tabs come in a variety of designs, ranging from functional pieces to decorative additions.

-

Function: Lets the user move the slider with minimal effort.

-

Customization: Pull tabs can be customized with logos or unique designs to enhance branding opportunities.

5. Top Stop

The top stops are small components located at the top of the zipper tape, preventing the slider from coming off.

-

Function: Acts as a stopper to secure the slider in place at the top.

-

Material: Typically made of metal or plastic. Sturdy top stops are essential for durability.

6. Bottom Stop

Similar to the top stop, the bottom stop secures the other end of the zipper and keeps the teeth aligned. Just below the bottom stop, there is a bottom tape extension—the fabric portion of the zipper tape that extends beyond the bottom stop, providing extra durability and a secure area for attachment. On open-end zippers, the retainer box is located on one side of the zipper at the bottom, just below the teeth, to help align and connect the zipper halves.

-

Function:

-

Open-End Zippers (e.g., jackets): The bottom stop allows the zipper to completely separate when unzipped.

-

Closed-End Zippers (e.g., pants): Prevents the slider from detaching and ensures a fully closed end.

Material: Usually metallic for durability.

How the Parts Work Together

Every part of a zipper plays a role in its functionality. The tape anchors the zipper to the fabric. The teeth, guided by the slider, interlock seamlessly to create a closure. The pull tab ensures ease of use, while the top and bottom stops keep everything in place. Together, these components form a reliable closure system that’s easy to operate.

Types of Zippers

There are three main types of zippers: coil, stamped plastic, and stamped metal. These main types each have distinct features and identification methods, and come in different styles to suit various applications.

Zippers are not one-size-fits-all. Different applications require specific types of zippers, each with unique components and different uses depending on the product—such as home decor, bags, or apparel.

-

Metal Zippers: One of the main types, ideal for heavy-duty items like jeans, leather jackets, and backpacks. Their different uses include providing strength and durability in products that undergo frequent stress.

-

Coil Zippers (Nylon Zippers): Another main type, lightweight and flexible, used in dresses, cushions, and tents. These are often chosen for their smooth operation and adaptability to curved seams, making them suitable for a variety of patterns.

-

Invisible Zippers: Designed to blend into garments, making them perfect for formalwear and any sewing patterns where a concealed closure is desired.

-

Separating Zipper: This type allows garments or bags to be completely opened, as in coats or outerwear. A separating zipper fully comes apart into two separate pieces, thanks to its starter box and insertion pin, making it essential for jackets and similar items.

-

Waterproof Zippers: Designed with coated tape for outdoor gear and wet-weather apparel, these are used in patterns that require water resistance.

When selecting a zipper, it’s important to have a good stock of different zipper types and components, such as sliders, chains, and stops, to ensure you have the right option for your project. Zippers also come in various styles, such as old style and new style, which can affect compatibility and application.

Understanding the intended use of your product and the requirements of your sewing patterns helps in selecting the perfect type of zipper.

Maintenance Tips for Zippers

To ensure zippers last as long as possible, proper care is essential. Here are some maintenance tips:

-

Clean Regularly: Dust and debris can build up in the teeth and slider, preventing smooth operation.

-

Lubricate when Needed: Use a silicone-based zipper lubricant to keep the slider moving freely.

-

Inspect Stops: Check top and bottom stops for wear and replace if damaged to avoid malfunctions.

-

Avoid Overloading: For bags and luggage, don’t exceed recommended weight limits to prevent zipper strain.

-

Store Properly: When storing items with zippers, keep them slightly open to avoid putting unnecessary tension on the teeth.

-

Repair Minor Issues: Minor zipper issues can often be repaired by replacing specific parts, such as a worn slider or damaged stop.

-

If you notice a break or find that a component is broken, it may need to be replaced. Sometimes, installing a new slider can fix the problem, but if the teeth or starter box are broken, a new zipper may be required.

-

For best results, follow a step by step guide to repair or replace zipper components safely and effectively.

Want more tips? Sign up for our detailed zipper repair guide or newsletter!

Why Zippers Matter

Zippers may seem like small components, but their functionality, durability, and aesthetic appeal directly impact the quality of a product. Whether you’re manufacturing high-end garments or rugged sports bags, choosing the right zipper and maintaining it properly can elevate your product and enhance customer satisfaction.

For more insights and top-quality zippers tailored to your needs, explore [Brand Name]’s complete range of zippers and tailoring materials.