How Is Thick Elastic Band Used in Industrial Garment Manufacturing?

In today’s competitive garment manufacturing industry, the quality and durability of every component directly impacts the final product’s performance and customer satisfaction. Among these critical components, thick elastic band stands as a cornerstone material that determines whether industrial garments meet the rigorous demands of professional environments or fall short of expectations. Heavy duty elastic bands are designed to withstand heavy use and prolonged stress, making them essential for industrial applications. Additionally, heavy duty elastic is made from high quality materials such as polyester, spandex, or rubber to ensure superior performance and longevity.

As global B2B manufacturers and suppliers understand, the difference between standard elastic and heavy duty elastic band can make or break a product line. Industrial garment production requires materials that withstand thousands of wash cycles, maintain consistent stretch properties under extreme conditions, and deliver reliable performance across diverse applications from workwear to safety equipment. Thick elastic bands are built to endure these challenges, offering robust construction that stands up to outdoor conditions and heavy use.

This comprehensive guide examines everything garment factories and wholesalers need to know about thick elastic band specifications, applications, and sourcing strategies. From understanding material compositions to optimizing bulk purchasing decisions, we’ll explore how the right elastic band selection impacts both production efficiency and end-user satisfaction.

What is Thick Elastic Band

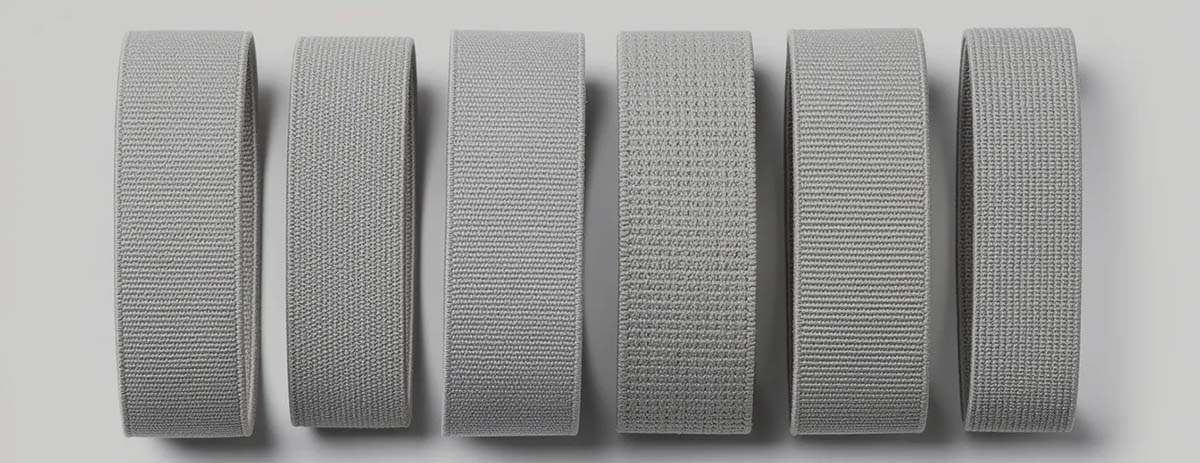

Thick elastic band represents a specialized category of heavy duty elastic materials engineered specifically for demanding industrial applications where standard elastic simply cannot deliver adequate performance. Unlike lightweight elastic used in consumer apparel, thick elastic band features enhanced width and thickness specifications designed to handle substantial loads while maintaining consistent elasticity over extended use cycles. Thick elastic bands are available in various sizes and widths to suit different needs.

The fundamental distinction lies in both physical dimensions and material density. Standard elastic typically measures 0.5 to 1 inch in width with minimal thickness, while thick elastic band ranges from 1 inch to 4 inches in width with thickness options spanning 2mm to 8mm. This increased material volume translates directly into superior load-bearing capacity and enhanced durability for industrial applications. Thick elastic bands can be easily cut to the desired length to fit specific applications.

Primary applications in garment manufacturing focus on structural support elements including waistbands, cuffs, and reinforcement areas where consistent tension and long-term reliability are paramount. Thick elastic bands can be used in various applications including garment manufacturing, packaging, and outdoor gear. Heavy duty elastic band excels in work uniforms, safety gear, and activewear where component failure could compromise user safety or product integrity.

The performance differential between standard and thick elastic becomes evident under stress testing. Where standard elastic may lose elasticity after 500-1000 stretch cycles, quality thick elastic band maintains consistent properties through 10,000+ cycles. Heavy duty elastic bands are designed for heavy use and can withstand continuous use without losing elasticity. This durability makes it essential for professional garments subjected to frequent washing, extended wear periods, and challenging working conditions.

Manufacturing Specifications and Material Types

Modern thick elastic band manufacturing employs sophisticated material engineering to meet diverse industrial requirements. Understanding these specifications enables garment manufacturers to select optimal materials for their specific applications while ensuring consistent quality and performance across production runs.

Quality control measures in industrial elastic production include precision thickness monitoring, stretch ratio testing, and durability validation through accelerated aging protocols. Leading manufacturers implement ISO 9001 quality management systems ensuring every batch meets specified tolerances and performance criteria.

Material Composition Options

The foundation of thick elastic band performance lies in carefully engineered material compositions tailored to specific application requirements. Each material system offers distinct advantages that garment manufacturers must evaluate against their production needs and end-use requirements.

Polyester core with spandex covering represents the most versatile option for maximum stretch recovery applications. This combination typically features 80% polyester core fibers providing structural strength, with 20% spandex covering delivering exceptional elasticity. The polyester component ensures dimensional stability and resistance to environmental factors, while spandex contributes superior stretch ratios reaching 300-400% elongation with excellent recovery properties.

Rubber-based thick elastic serves heavy-duty industrial applications requiring maximum strength and chemical resistance. These formulations often combine natural or synthetic rubber with textile reinforcement, creating elastic bands capable of withstanding harsh industrial environments. Rubber-based varieties excel in safety equipment, protective gear, and workwear where elastic failure could create safety hazards.

Cotton-polyester blends address comfort requirements in direct skin contact garments. These compositions typically feature 70% cotton for softness and breathability, combined with 30% polyester for strength and stretch properties. This blend provides comfortable wear characteristics while maintaining adequate performance for moderate-duty applications like uniforms and casual workwear.

Specialty materials serve niche applications requiring flame-resistant and chemical-resistant properties. Meta-aramid fibers create fire-retardant elastic meeting aerospace and automotive safety standards, while specialized polymer compositions resist degradation from chemicals, oils, and extreme temperatures.

Width and Thickness Specifications

Standardized width options ensure compatibility with industrial sewing equipment and garment design requirements. Standard widths include 1”, 1.5”, 2”, 2.5”, 3”, and 4” to accommodate different garment applications from lightweight activewear to heavy-duty safety equipment.

The 1” width serves most activewear and lightweight uniform applications, providing adequate support without excessive bulk. This size integrates easily into standard garment construction techniques and offers good stretch properties for moderate-duty use.

Wider specifications from 2” to 4” address heavy-duty applications requiring maximum support and load distribution. These widths excel in work pants, safety harnesses, and industrial uniforms where elastic performance directly impacts user safety and comfort during extended wear periods.

Thickness options ranging from 2mm to 8mm allow precise matching of elastic properties to load requirements. Thinner options (2-3mm) work well for activewear and lightweight garments, while thicker specifications (6-8mm) provide the strength needed for industrial safety equipment and heavy-duty workwear.

Custom sizing capabilities enable manufacturers to optimize elastic specifications for specific production needs. Experienced suppliers can produce non-standard widths and thicknesses to meet unique design requirements, though minimum order quantities typically apply for custom specifications.

Tolerance standards ensure consistent manufacturing quality across large production runs. Industry-standard tolerances maintain width variations within ±2% and thickness variations within ±5%, enabling reliable garment construction and consistent performance characteristics.

Applications in Garment Manufacturing

The versatility of thick elastic band makes it indispensable across diverse garment manufacturing sectors. Heavy duty elastic bands can also be used in industrial webbing, packaging, and outdoor gear, making them suitable for a wide range of applications. Understanding specific application requirements helps manufacturers select optimal elastic specifications while ensuring end products meet performance expectations and regulatory requirements.

Performance requirements vary significantly between application types, necessitating careful material selection and specification matching. Heavy duty elastic bands are often used for securing items during transit and bundling packages, especially in packaging and shipping contexts. Industrial standards govern elastic performance in safety-critical applications, while comfort and durability considerations drive selections for general workwear and activewear.

Waistbands and Structural Support

Waistband applications represent the highest-volume use of thick elastic band in industrial garment manufacturing. Work pants, uniforms, and heavy-duty trousers require elastic that maintains consistent tension throughout extended wear cycles while providing comfortable support during physical activity.

Load distribution considerations become critical for garments designed for extended wear. A 2” thick elastic band distributes waistband pressure more evenly than narrower alternatives, reducing pressure points and improving wearer comfort during 8-12 hour work shifts. This comfort factor directly impacts worker productivity and garment acceptance in industrial environments.

Attachment methods for industrial production must withstand commercial washing and industrial use conditions. Standard techniques include cover-stitched seaming, bartacked reinforcement, and multiple-pass construction ensuring elastic attachment points remain secure through hundreds of wash cycles and extreme use conditions.

Durability requirements for commercial washing present unique challenges. Industrial laundry operations often employ high-temperature wash cycles, aggressive chemicals, and mechanical stress that would quickly degrade consumer-grade elastic. Heavy duty elastic band must maintain elasticity and structural integrity through these harsh processing conditions while retaining dimensional stability.

Sewing techniques optimized for thick elastic require specialized equipment and operator training. Industrial sewing machines must accommodate increased material thickness, while operators need understanding of proper tension settings and feed rates to ensure consistent seam quality. Proper technique prevents elastic stretching during construction, ensuring finished garments maintain intended fit and performance characteristics.

Activewear and Sportswear Manufacturing

Athletic wear applications demand thick elastic band that combines high stretch ratios with rapid recovery properties. Sports and fitness activities subject elastic to repeated rapid stretching cycles, requiring materials that return to original dimensions quickly and consistently.

Performance testing for sports applications includes fatigue resistance evaluation, where elastic undergoes thousands of stretch cycles simulating athletic activity. Quality thick elastic band maintains consistent performance through extended testing, ensuring athletic garments retain fit and support characteristics throughout their useful life.

Moisture management considerations affect material selection for activewear applications. Synthetic elastic compositions resist moisture absorption, preventing bacterial growth and odor development during athletic use. Some specialty formulations include antimicrobial treatments providing additional protection against bacteria and fungi.

Color fastness requirements ensure athletic garments maintain appearance through repeated washing and UV exposure. Quality thick elastic band incorporates colorfast dyes and UV-resistant additives preventing fading and discoloration during outdoor activities and commercial laundering.

Industrial Workwear and Safety Garments

Safety-critical applications represent the most demanding use of thick elastic band, where component failure could create serious safety hazards. Safety harnesses, protective gear, and industrial uniforms require elastic meeting rigorous performance standards and regulatory compliance requirements.

Compliance with safety standards such as ANSI, OSHA, and international equivalents often mandates specific elastic performance characteristics. Load-bearing capacity, flame resistance, and chemical resistance requirements vary by application, necessitating careful material selection and specification verification.

Chemical resistance properties become essential for garments used in industrial environments. Specialized thick elastic formulations resist degradation from oils, solvents, acids, and other industrial chemicals, maintaining performance characteristics despite exposure to harsh substances.

Integration with safety features requires careful design consideration. Elastic components must interface properly with reflective materials, flame-resistant treatments, and other safety elements without compromising overall garment protection or performance.

Temperature performance ranges accommodate diverse working environments from cold storage facilities to high-temperature industrial processes. Quality thick elastic maintains flexibility and performance characteristics across temperature ranges from -40°F to 200°F, ensuring consistent garment performance regardless of environmental conditions.

Bulk Ordering and Wholesale Advantages

Volume pricing structures provide significant cost advantages for large-quantity purchases, enabling garment manufacturers to reduce material costs while ensuring consistent supply availability. Bulk ordering also provides priority access to production capacity during peak demand periods.

Inventory management support helps customers optimize their supply chains through flexible delivery schedules and vendor-managed inventory programs. These services reduce customer inventory carrying costs while ensuring material availability for production requirements.

Global shipping capabilities ensure reliable delivery regardless of customer location. Experienced logistics networks optimize shipping costs and transit times while providing tracking and documentation meeting international trade requirements.

Just-in-time delivery options synchronize elastic delivery with customer production schedules, reducing inventory requirements while ensuring materials arrive when needed. This service requires close coordination but can significantly reduce customer working capital requirements.

Long-term supply agreements provide price stability and guaranteed capacity allocation for customers with ongoing requirements. These agreements protect against material shortages during peak demand periods while providing predictable costs for financial planning.

Quantity discounts reward larger orders with reduced per-unit pricing, typically beginning at 10,000-yard orders and increasing with volume. Discount structures vary by product type and customization requirements, but substantial savings are available for high-volume customers.

Partnership benefits extend beyond pricing to include technical support, product development assistance, and priority customer service. Long-term relationships enable suppliers to better understand customer needs and provide proactive support for new product development and production optimization.

Contact MH for Your Thick Elastic Band Requirements

MH brings over 15 years of specialized experience in thick elastic band manufacturing, serving global garment factories with comprehensive solutions from standard products to complex custom specifications. Our technical expertise and production capabilities make us the reliable partner garment manufacturers need for consistent quality and competitive pricing.

Our comprehensive product range spans 1” to 4” width thick elastic bands in multiple material compositions and performance specifications. Whether your application requires basic polyester-spandex blends for activewear or specialized fire-retardant materials for safety equipment, MH maintains inventory and production capabilities to meet diverse requirements efficiently.

Quality evaluation through our free sample service enables customers to test material properties and verify compatibility with their specific applications before committing to large orders. Samples include detailed specification sheets and performance data supporting informed purchasing decisions.

Bulk pricing quotes for quantities starting from 10,000 yards provide transparent cost information enabling accurate project budgeting and cost analysis. Our pricing structure rewards volume purchases while maintaining competitive rates for customers with ongoing requirements.

OEM/ODM inquiries receive dedicated technical support to develop optimal solutions for specific applications. Our product development team works closely with customers to create custom specifications meeting unique performance requirements while optimizing production efficiency and cost structure.

Custom manufacturing projects benefit from our flexible production capabilities and technical expertise in material science and textile engineering. From prototype development through full production, MH provides comprehensive support ensuring successful project completion.

Partner with MH to establish a reliable supply chain foundation supporting your garment manufacturing success. Our commitment to quality, competitive wholesale pricing, and comprehensive customer support makes us the ideal choice for thick elastic band requirements across all industrial applications.

Contact our B2B sales team today to discuss your specific requirements and discover how MH’s thick elastic band solutions can enhance your product quality while optimizing your supply chain efficiency and cost structure.

For those sourcing thick elastic bands, fabric stores that sell upholstery fabric often have a variety of thick elastic bands available. Joann fabric stores, especially larger locations, may also offer thick elastic options. Additionally, suspender elastic can be a good alternative for finding thick elastic bands. Thick elastic bands are not only used in industrial and garment applications but are also suitable for home organization and storage needs, making them a versatile choice for home use.