What Is 840D Nylon and Why Is It Known for Ultimate Durability?

What makes 840D nylon so durable? This article explains its strength, uses, and unique features. You’ll learn why it’s a top choice for backpacks, tactical gear, and more.

Key Takeaways

-

840D nylon fabric is known for its exceptional durability, tensile strength, and resistance to environmental factors, making it ideal for demanding applications in medical, tactical, industrial, and outdoor sectors.

-

It offers various coating options, such as PU and PVC, which enhance its properties like waterproofing, UV resistance, and mildew resistance, allowing customization for specific needs.

-

MH provides comprehensive customization and bulk supply options, ensuring consistent quality and cost-effectiveness, backed by over 25 years of industry experience.

Understanding 840D Nylon

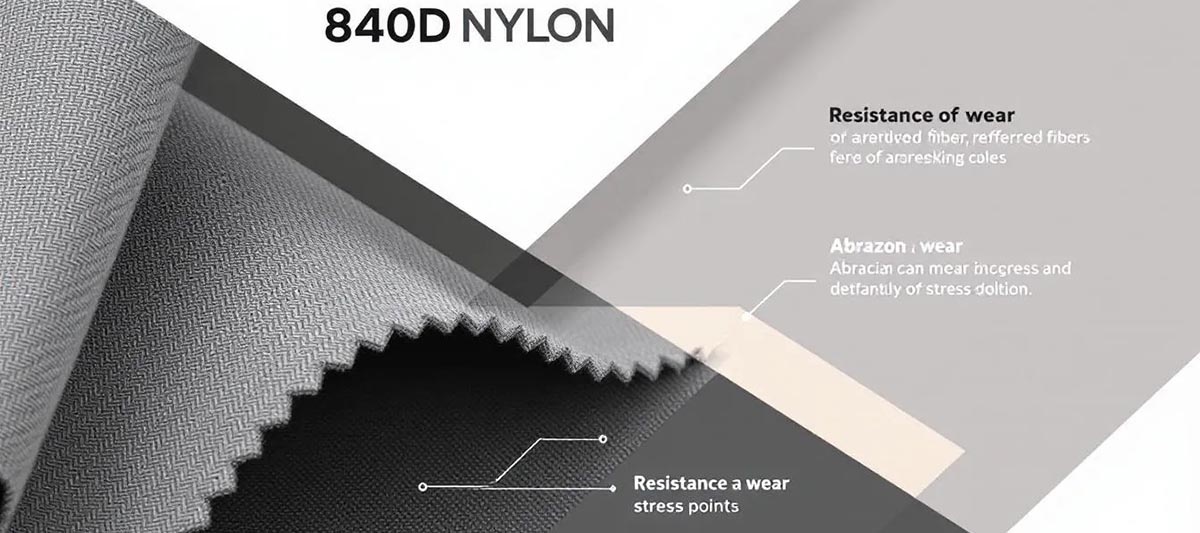

840D nylon is not just any fabric; it’s an industrial powerhouse designed for high durability and strength. This fabric is often employed in medical and tactical applications, where robustness is non-negotiable. Made from 100% nylon (polyamide), it combines high durability with resistance to wear and tear, making it a top choice for demanding environments.

The woven structure of 840D nylon is fundamental to its strength and stability. This heavy-duty woven polyamide fabric is known for its exceptional strength, abrasion resistance, and long-lasting durability. The weaving process ensures that the fabric can withstand significant stress and strain, essential for heavy-duty usage in various sectors.

One of the standout qualities of 840D nylon is its ability to balance toughness and flexibility. This makes it suitable for both consumer and industrial applications. Whether it’s a backpack that needs to endure the rigors of daily use or a piece of tactical gear that must perform in extreme conditions, 840D nylon rises to the occasion.

In the healthcare sector, this fabric is a preferred choice due to its robustness and ease of cleaning. Industrial applications also benefit from its stability and strength, making it an ideal textile material for products that must endure harsh conditions. Its versatility extends to outdoor applications as well, where it is valued for its ability to resist environmental wear and tear.

With such a strong foundation, it’s no wonder that 840D nylon fabric has become a great staple in various industries. Its unique combination of strength, durability, and flexibility ensures that it meets the high standards required for medical, tactical, industrial, and outdoor applications.

Key Features of 840D Nylon

One of the primary reasons 840D nylon is so highly regarded is its impressive tensile strength. This fabric can withstand significant stress without tearing, making it ideal for demanding applications where durability is paramount. MH 840D nylon fabric, in particular, is known for its high tensile strength, excellent abrasion and tear resistance, and overall robustness.

Another critical feature of 840D nylon is its resistance to environmental factors, including:

-

Coating with a Durable Water Repellent (DWR) finish, enhancing its resistance to moisture

-

Being made fully waterproof, adding another layer of protection

-

Resistance to UV rays, ensuring it maintains its integrity even when exposed to the sun for prolonged periods

The longevity of 840D nylon fabric cannot be overstated. Its ability to resist wear and tear over time makes it a reliable choice for products that need to last. Whether used in tactical gear, luggage, or industrial covers, this fabric’s durability ensures that it continues to perform well, even under tough conditions. This combination of features makes it an excellent choice for various high-demand applications.

Common Applications of 840D Nylon

One of the most common applications of 840D nylon is in the construction of backpacks. This fabric’s durability and resistance to abrasion make it perfect for products that need to withstand daily wear and tear. Whether you’re hiking through rugged terrain or navigating the urban jungle, a backpack made from 840D nylon will hold up under pressure.

Tactical gear is another area where 840D nylon excels. The bulletproof fabric provides the strength and functionality needed in demanding conditions. From military bags to tactical vests, its robustness ensures that the gear can handle the stress of challenging environments while protecting the items within.

Luggage manufacturers also favor 840D nylon for its robust nature and water-resistant properties. A suitcase made from this fabric can endure the rigors of travel, from being tossed around by baggage handlers to exposure to various weather conditions. Its durability ensures that your belongings remain safe and secure.

Outdoor equipment is another sector that benefits immensely from 840D nylon. This fabric is often used in tents, tarps, and other gear that must withstand harsh weather and physical stress. Industrial covers and protective cases also utilize this fabric to provide protection against environmental elements and physical impacts. The versatility of 840D nylon across these product categories highlights its broad applicability and reliability.

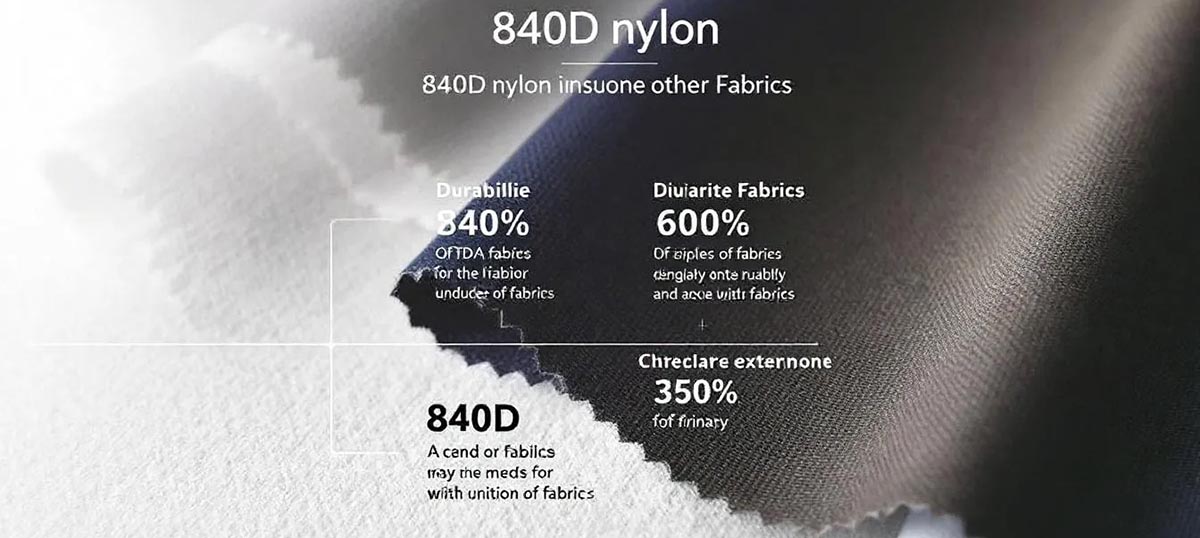

Comparing 840D Nylon with Other Fabrics

When it comes to heavy-duty fabrics, 840D nylon is often compared to CORDURA. While both are known for their durability, there are key differences. Ballistic Nylon, which includes 840D nylon, generally has superior tensile and tear strength compared to CORDURA. This makes it better suited for carrying heavy loads and applications where maximum strength is required.

CORDURA fabrics, on the other hand, often exhibit greater abrasion resistance due to their air-textured yarn. This makes CORDURA a popular choice for products that need to resist surface wear, such as apparel and footwear. However, Ballistic Nylon’s superior tensile strength means it can handle more substantial stress without tearing.

Quality consistency is another factor to consider. CORDURA is easier to identify and consistently meets quality standards, whereas Ballistic Nylon’s quality may vary among brands. This can influence the decision on which fabric to use based on the specific requirements of the application.

Choosing between these fabrics depending on the specific needs of the application. For example, 840D nylon is the better choice if weight tolerance and maximum durability are critical. On the other hand, if abrasion resistance is the primary concern, CORDURA might be more suitable. Understanding these differences is crucial for ensuring the performance and longevity of the products made from these fabrics.

In the world of textiles, no one fabric is perfect for all applications. Understanding the unique properties of different types of nylon fabric helps in making informed decisions that align with the intended use. Whether you are designing outdoor gear, tactical equipment, or industrial covers, knowing the strengths and limitations of each fabric can significantly impact the quality and durability of the final product.

Coating Options for 840D Nylon

Coating options for 840D nylon significantly enhance its versatility and performance. One common coating is PU (polyurethane), which increases the fabric’s durability and water resistance. This makes it suitable for applications where exposure to moisture is a concern.

PVC (polyvinyl chloride) coatings are another option, providing a moisture barrier and improved strength. This makes PVC-coated 840D nylon ideal for applications requiring enhanced water resistance and durability. Additionally, a Durable Water Repellent (DWR) coating can be applied to make the fabric water-resistant.

Beyond water resistance, coatings can also provide other protective features. For instance, UV-resistant coatings enhance the fabric’s longevity in outdoor environments by protecting it from the sun’s harmful rays and help to prevent damage. Mildew-resistant coatings are also available, making the fabric suitable for humid conditions.

Aesthetic considerations are not left out, as matte and glossy finishes can be achieved through various coating methods. These finishes impact the fabric’s look and feel, allowing for customization based on the desired appearance of the final product. MH offers a range of coating options, including:

-

PU

-

PVC

-

Waterproof

-

Water-repellent

-

Matte finishes

-

Glossy finishes

These coatings not only enhance the fabric’s functional properties but also expand its potential applications. Whether you need a waterproof, UV-resistant, or mildew-resistant fabric, the right coating can tailor 840D nylon to meet specific needs.

Customization and Bulk Supply of 840D Nylon

Customization options for 840D nylon are extensive, allowing for a lot of diverse product designs and personal expression. Customer appreciation for the ability to tailor products to their specific needs, whether that involves choosing a particular color or add specific coatings for enhanced performance.

Buy 840D nylon in bulk from MH to send significant cost savings and ensure consistent quality across large orders. The minimum order quantity for tailored orders is 1000 yards per color, making it feasible for both large and small businesses to customize their products. Delivery for bulk orders typically ranges from 15 to 25 days after order confirmation.

MH provides OEM/ODM customization for 840D nylon fabrics, including:

-

Coating

-

Color

-

Weight These options ensure that the fabric meets the specific requirements of any project, making it possible to create unique and high-quality products tailored to specific market needs.

MH also offers bulk wholesale supply with stable quality, factory-direct pricing, and fast delivery. Their 840D nylon fabric is packaged in a roll and supplied in bulk, making it convenient for manufacturers and distributors. This reliable supply chain ensures that businesses can depend on MH for their fabric needs.

Why Choose MH for 840D Nylon Fabric?

MH stands out in the nylon fabric industry for several surprising reasons. With over 25 years of expertise, the company has built a reputation for consistently delivering high-quality products. This experience translates into a deep understanding of the needs of various industries and the ability to meet those needs effectively.

Quality is a cornerstone of MH’s offerings. The company ensures that its 840D nylon fabric meets the highest standards of durability and performance. This commitment to quality makes MH a trusted supplier for businesses interested in reliable materials sold for their products.

Competitive pricing is another advantage of working with MH. The company offers factory-direct pricing, making its products accessible to a wide range of customers. This cost-effectiveness, combined with high-quality materials, provides excellent value.

Finally, MH ensures a stable and reliable long-term supply of materials. Their global distribution network, spanning over 150 countries, ensures that customers can depend on MH to continue for timely deliveries and consistent product availability. This makes MH a one-stop solution for sourcing high-quality nylon fabrics and related accessories, including shipping.

Summary

Understanding the benefits and applications of 840D nylon fabric can significantly influence your product choices. This fabric’s exceptional strength, durability, and versatility make it a preferred choice across various industries. Whether for tactical gear, outdoor equipment, or industrial applications, 840D nylon stands out for its performance.

Choosing MH as your supplier ensures that you receive top-quality fabric, competitive pricing, and reliable delivery. With their extensive experience and commitment to quality, MH is the ideal partner for all your nylon fabric needs.

Frequently Asked Questions

What makes 840D nylon fabric so durable?

840D nylon fabric's durability comes from its 100% nylon composition, offering high tensile strength and exceptional resistance to abrasion and tearing. This combination ensures it lasts through extensive use, making it a reliable choice for various applications.

What are the common applications of 840D nylon?

840D nylon is widely utilized in backpacks, luggage, tactical gear, outdoor equipment, and industrial covers due to its durability and environmental resistance. This makes it an ideal choice for products that require strength and protection.

How does 840D nylon compare to CORDURA?

840D nylon offers better tensile and tear strength, making it ideal for heavy loads, while CORDURA excels in abrasion resistance thanks to its air-textured yarn. Ultimately, the choice depends on your specific needs for durability versus abrasion protection.

What coating options are available for 840D nylon?

Coating options for 840D nylon include PU, PVC, water-repellent, and UV or mildew-resistant finishes, along with matte and glossy options. These coatings enhance durability and performance for various applications.

Why should I choose MH for 840D nylon fabric?

Choosing MH for 840D nylon fabric guarantees you high-quality products backed by over 25 years of expertise, competitive pricing, and a reliable supply chain for consistent delivery. Their established reputation makes them a dependable choice for your fabric needs.